Synthetic resin binder-molded solid acid, and method for producing same

A technology of synthetic resin and binder, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalyst, etc., can solve the problems of binder deterioration, insufficient chemical resistance, low catalyst activity, etc. Achieving a high degree of freedom and avoiding the degradation of catalyst performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

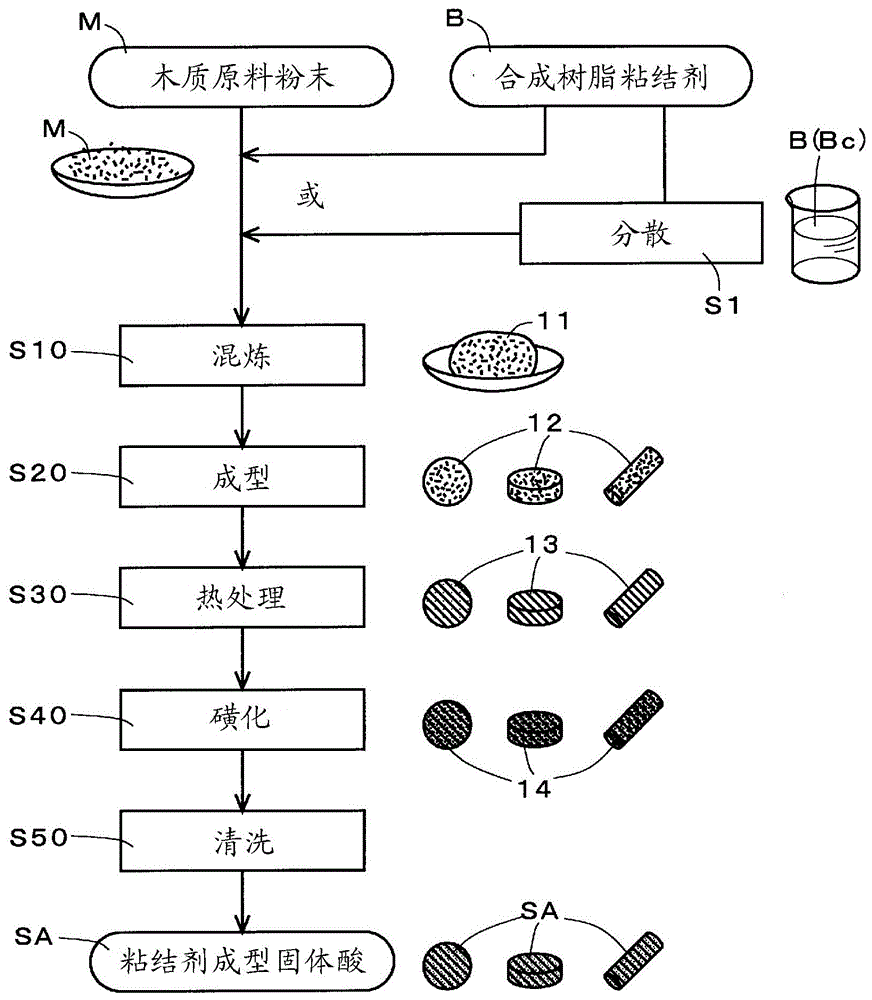

Method used

Image

Examples

preparation example Construction

[0060] The molded solid acid produced by the production methods illustrated and described in detail so far has a relatively high degree of freedom in the blending ratio of the wood raw material powder or in the design of the shape. Therefore, they can be prepared separately according to the desired use and purpose. In particular, since the solid acid is formed into a molded product of a predetermined shape, separation and recovery after use in a catalytic reaction become easy, and the usability at the time of use is greatly improved.

[0061] The present invention is characterized in that the binder contained in the molded solid acid is a synthetic resin, and finally the binder and the wood raw material powder are heat-treated simultaneously. The bonding of various raw materials to each other is promoted by heat treatment. Needless to say, the binder used in the molded solid acid of the present invention does not have the property of finally binding and integrating powdered s...

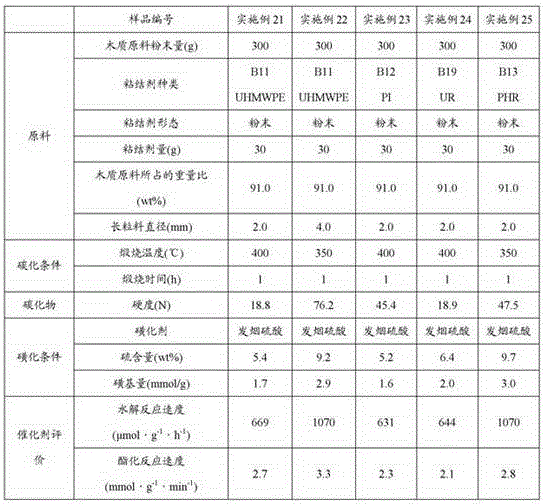

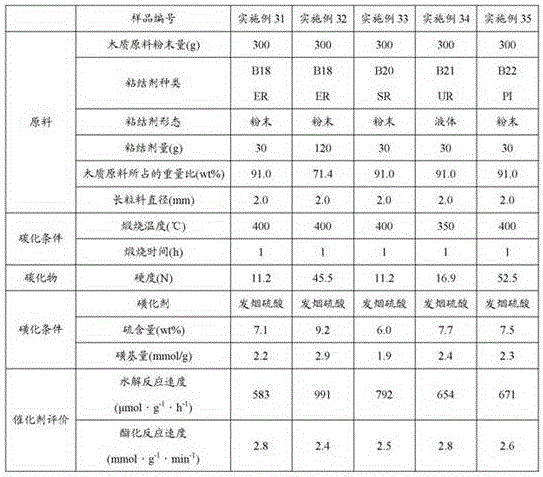

Embodiment

[0065] [use raw materials]

[0066]

[0067] As the polyethylene aqueous dispersion, an aqueous dispersion (low-density polyethylene (LDPE), trade name "Chemipearl (Chemipear) M200") manufactured by Mitsui Chemicals, Ltd. {binder B1} was used.

[0068] As the polyethylene powder, low-density polyethylene (LDPE) manufactured by Sumitomo Chemical Co., Ltd., trade name "Sumikathene G801" {binder B2} was used.

[0069] As the polyethylene powder, high-density polyethylene (HDPE) manufactured by Prime Polymer Co., Ltd. (KK Prime Polymer), product name "Hi-Zex (Hi-Zex) 1608J" {binder B3} was used.

[0070] As the polyethylene powder, linear medium-density polyethylene (LMDPE) manufactured by Prime Polymer Co., Ltd. (KK Prime Polymer), product name "Neo-Zex (Neozex) 45200" {Binder B4} was used.

[0071] As the polyethylene powder, a linear low-density polyethylene (LLDPE) manufactured by Prime Polymer Co., Ltd. (Prime Polymer Co., Ltd.), a product name "Ultzex (ultzex) 20200J" {...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com