Magnetic chaff charcoal for removing lead and cadmium in water and preparation and application method thereof

A technology of biochar and chaff, applied in chemical instruments and methods, water pollutants, alkali metal compounds, etc., can solve the problems of magnetization that have not been reported yet, and achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

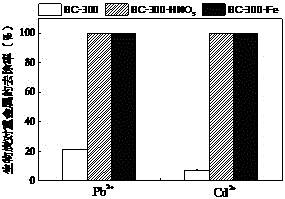

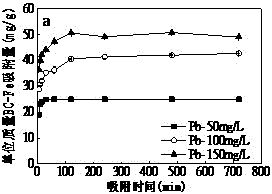

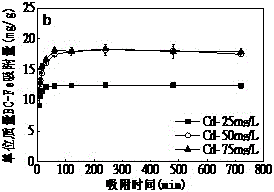

[0033] 1. Preparation of magnetic chaff biochar (BC-300-Fe)

[0034] (1) Wash and dry the chaff raw materials, heat at 300°C for 6 hours under nitrogen, carbonize and crush through a 100-mesh sieve, wash with 0.005mol / L nitric acid at a solid-to-liquid ratio of 1:10 to remove ash, and use ultrapure water Wash until neutral, and dry at 70°C to obtain chaff biochar;

[0035] (2) Take a certain amount of carbonized chaff and place it in 2mol / L nitric acid at a solid-to-liquid ratio of 1:20, and oxidize it at 110°C for 1.5h, stirring occasionally during this period. After cooling, wash with distilled water until the pH of the supernatant is neutral, and dry to obtain acid-modified chaff biochar;

[0036] (3) A certain proportion of FeCl3 6H 2 O and FeCl 2 4H 2 O mixed and dissolved in 0.5mol / L HCl solution, added to 0.9mol / L ammonia solution to form black Fe 3 o 4 Colloidal precipitate. Add a certain amount of carbonized rice husk, stir for 30 minutes, stand for separation,...

Embodiment 2

[0045] 1. Preparation of magnetic chaff biochar (BC-400-Fe)

[0046] (1) Wash and dry the chaff raw materials, heat at 400°C for 4 hours under nitrogen, carbonize and crush through a 100-mesh sieve, wash with 0.007mol / L nitric acid at a solid-to-liquid ratio of 1:15 to remove ash, and use ultrapure water Wash until neutral, and dry at 70°C to obtain chaff biochar (BC-400);

[0047] (2) Take a certain amount of carbonized chaff and place it in 2mol / L nitric acid at a solid-to-liquid ratio of 1:10, and oxidize it at 110°C for 2 hours, stirring occasionally during this period. After cooling, wash with distilled water until the pH of the supernatant is neutral, and dry to obtain acid-modified chaff biochar (BC-400-HNO 3 );

[0048] (3) A certain proportion of FeCl 3 ·6H 2 O and FeCl 2 4H 2 O mixed and dissolved in 0.4mol / L HCl solution, added to 0.7mol / L ammonia solution to form black Fe 3 o 4 Colloidal precipitate. Add a certain amount of carbonized rice husk, stir for 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturated adsorption capacity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com