Environment-friendly sewage purifier for electric discharge wire cutting machine tool and usage method

A technology for cutting machine tools and EDM wires, which is used in electric processing equipment, metal processing equipment, accessories, etc., can solve the problems of inability to clean, large manufacturing and use costs, and inability to filter, and achieves excellent purification effect. The effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

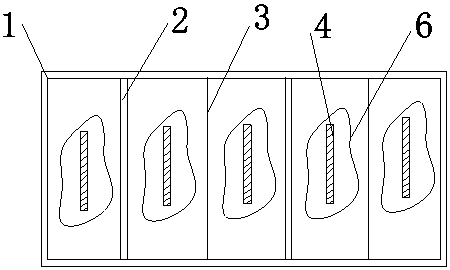

[0019] refer to figure 1 The shown environment-friendly sewage purifier for wire electric discharge machine tool includes wire electric discharge machine tool water tank 1, and the water tank 1 for wire electric discharge machine tool is divided into several compartments by plastic baffles, and any two adjacent The height of the plastic baffles is staggered, that is, a high baffle 2 is adjacent to a low baffle 3, and the water in two adjacent compartments flows from the bottom of the high baffle 2, or from the top of the low baffle 3 Wading.

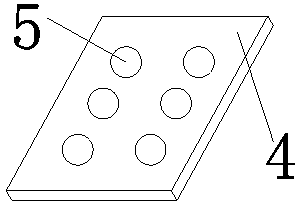

[0020] Plastic plate 4 is placed in each compartment, refer to figure 2 As shown, a plurality of magnets 5 are inlaid on the plastic plate 4, and a plastic bag 6 is covered on the plastic plate 4.

[0021] The using method of the present invention is as follows:

[0022] 1) Divide the water tank of the wire electric discharge cutting machine into several compartments through plastic baffles, any two adjacent plastic baffles are arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com