High-efficiency and low-cost grinding abrasive disc with flannelette back and production technology thereof

A production process, low-cost technology, applied in abrasives, grinding devices, manufacturing tools, etc., can solve the problems of high cost, low efficiency, complex production process, etc., to achieve the effect of high grinding efficiency and ensure safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

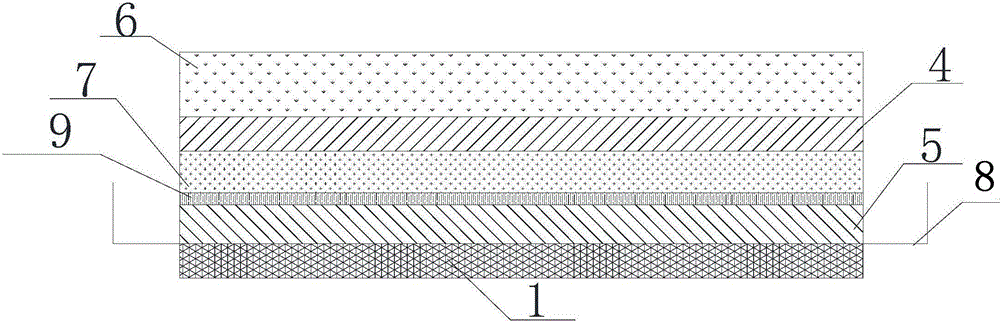

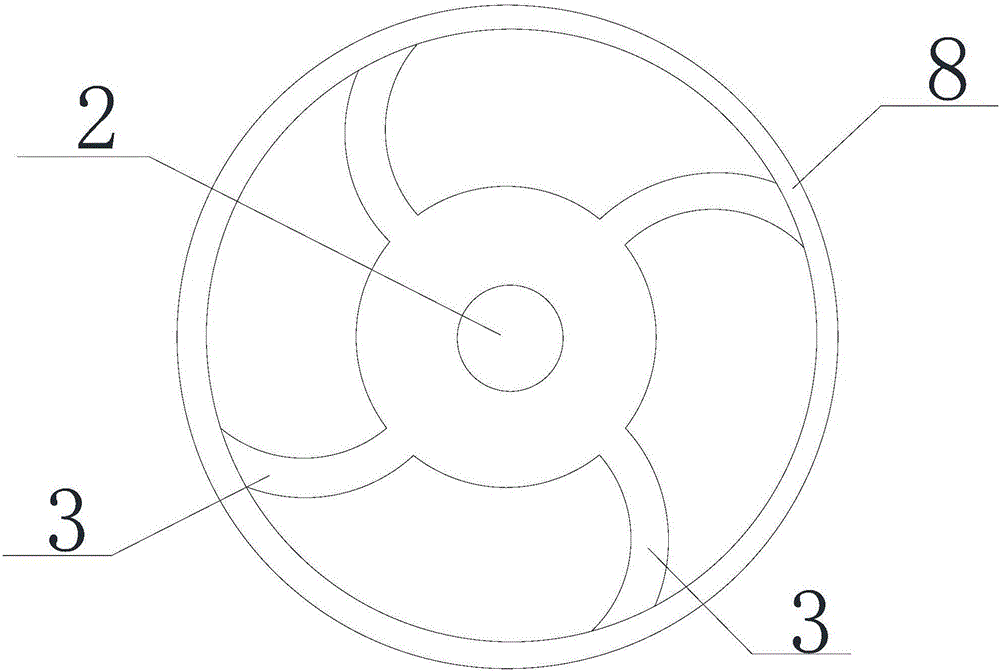

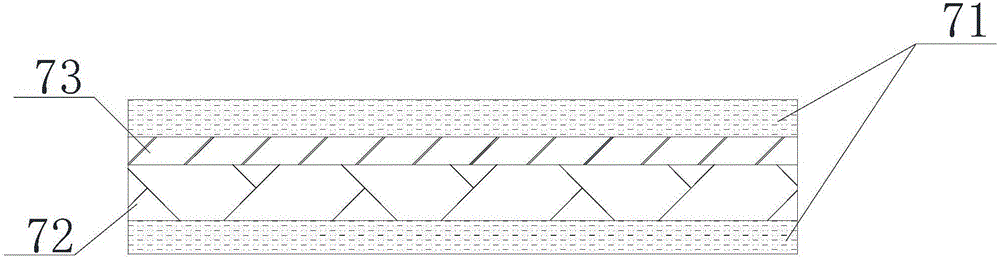

[0044] A kind of high-efficiency and low-cost cashmere grinding sand disc provided in this embodiment has a structure such as Figure 1-3 As shown, it includes a flannelette layer 1 and an abrasive cloth layer. The abrasive cloth layer includes a substrate layer and an abrasive layer. The center of the substrate layer is provided with an installation hole 2. The surface of the substrate layer is evenly distributed with spiral grooves 3. Inside the spiral groove 3 No binder, no abrasive, the substrate layer includes a first substrate layer 4 and a second substrate layer 5, the abrasive layer includes a first abrasive layer 6 and a second abrasive layer 7, and the upper surface of the first substrate layer 4 passes through The binder is bonded with the first abrasive layer 6, the lower surface of the first substrate layer 4 is bonded with the second abrasive layer 7 by the binder, and the second abrasive layer 7 is bonded away from the first substrate layer 4 by bonding. The bin...

Embodiment 2

[0065] A kind of high-efficiency and low-cost cashmere grinding sand disc provided in this embodiment has a structure such as figure 1 and 2 As shown, it includes a flannelette layer 1 and an abrasive cloth layer. The abrasive cloth layer includes a substrate layer and an abrasive layer. The center of the substrate layer is provided with an installation hole 2. The surface of the substrate layer is evenly distributed with spiral grooves 3. Inside the spiral groove 3 No binder, no abrasive, the substrate layer includes a first substrate layer 4 and a second substrate layer 5, the abrasive layer includes a first abrasive layer 6 and a second abrasive layer 7, and the upper surface of the first substrate layer 4 passes through The binder is bonded with the first abrasive layer 6, the lower surface of the first substrate layer 4 is bonded with the second abrasive layer 7 by the binder, and the second abrasive layer 7 is bonded away from the first substrate layer 4 by bonding. The...

Embodiment 3

[0086] A kind of high-efficiency and low-cost cashmere grinding sand disc provided in this embodiment has a structure such as figure 1 and 2 As shown, it includes a flannelette layer 1 and an abrasive cloth layer. The abrasive cloth layer includes a substrate layer and an abrasive layer. The center of the substrate layer is provided with an installation hole 2. The surface of the substrate layer is evenly distributed with spiral grooves 3. Inside the spiral groove 3 No binder, no abrasive, the substrate layer includes a first substrate layer 4 and a second substrate layer 5, the abrasive layer includes a first abrasive layer 6 and a second abrasive layer 7, and the upper surface of the first substrate layer 4 passes through The binder is bonded with the first abrasive layer 6, the lower surface of the first substrate layer 4 is bonded with the second abrasive layer 7 by the binder, and the second abrasive layer 7 is bonded away from the first substrate layer 4 by bonding. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com