Oxidative extraction method for hydrogen peroxide preparation through anthraquinone process and method for producing hydrogen peroxide

A technology of hydrogen peroxide and anthraquinone method, applied in the direction of peroxide/peroxy hydrate/peroxyacid/superoxide/ozonide, chemical instruments and methods, inorganic chemistry, etc., to achieve small liquid backmixing , improve the yield, save the effect of production equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0077] This embodiment is used to illustrate the oxidative extraction method and the method for producing hydrogen peroxide of the anthraquinone method of the present invention.

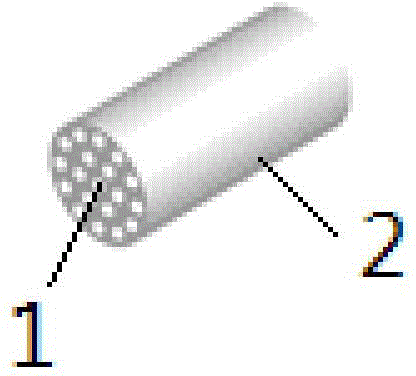

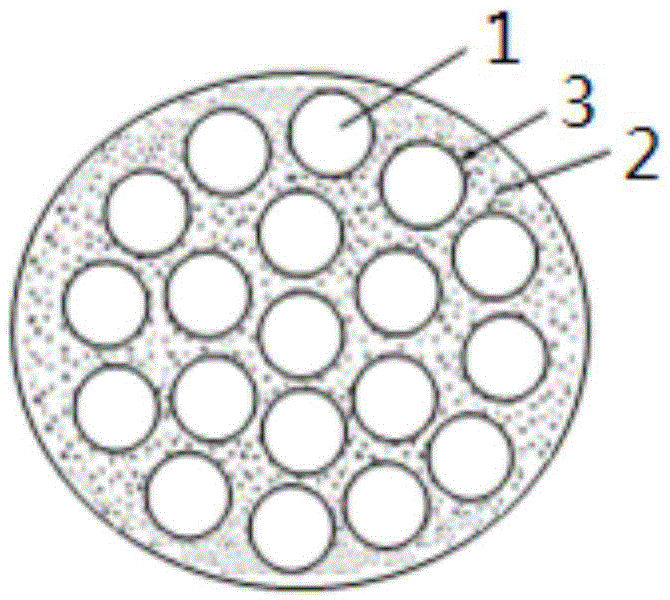

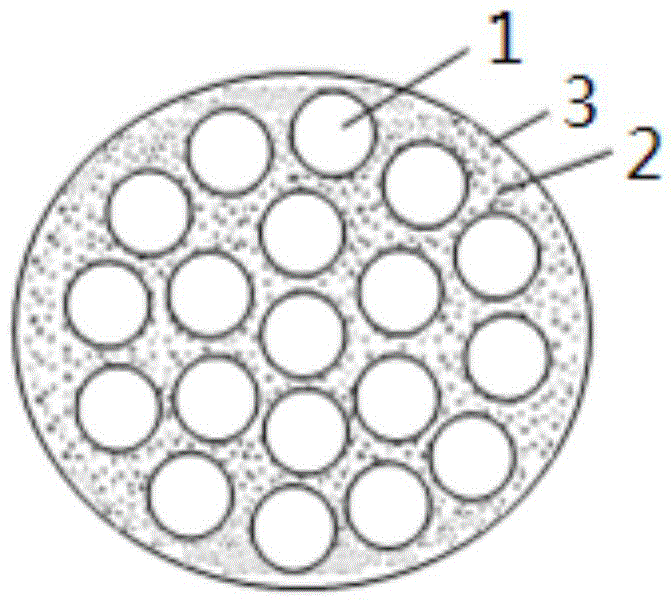

[0078] The mixing device used in this example is as Figure 4 As shown, the membrane tube used to connect the first channel and the second channel in the mixing device is as figure 2 As shown (commercially purchased from Beijing Zhongtianyuan Environmental Engineering Co., Ltd., there are 19 passages evenly distributed on the membrane tube, the inner diameter of each passage is 3.3mm, the average pore diameter of the pores on the substrate is 100nm, and the diameter of the pores on the porous membrane is 100nm. The average pore size is 30nm). A housing is used in cooperation with the membrane tube, the space formed by the outer wall of the membrane tube and the inner wall of the housing is used as the first channel, and the channel on the membrane tube is used as the second channel, and the first c...

Embodiment 2

[0086] This embodiment is used to illustrate the oxidative extraction method and the method for producing hydrogen peroxide of the anthraquinone method of the present invention.

[0087] The mixing device used in this example is as Figure 4 As shown, the membrane tube used to connect the first channel and the second channel in the mixing device is as figure 2 As shown (commercially purchased from Beijing Zhongtianyuan Environmental Engineering Co., Ltd., there are 4 passages evenly distributed on the membrane tube, the inner diameter of each passage is 3.3mm, the average pore diameter of the pores on the substrate is 5000nm, and the diameter of the pores on the porous membrane is 5000nm. The average pore diameter is 200nm). A housing is used in cooperation with the membrane tube, the space formed by the outer wall of the membrane tube and the inner wall of the housing is used as the first channel, and the channel on the membrane tube is used as the second channel, and the f...

Embodiment 3

[0095] This embodiment is used to illustrate the oxidative extraction method and the method for producing hydrogen peroxide of the anthraquinone method of the present invention.

[0096] The mixing device used in this example is as Figure 4 As shown, the membrane tube used to connect the first channel and the second channel in the mixing device is as figure 2 As shown (commercially purchased from Beijing Zhongtianyuan Environmental Engineering Co., Ltd., there are 10 channels evenly distributed on the membrane tube, the inner diameter of each channel is 3.3mm, the average pore diameter of the pores on the substrate is 200nm, and the diameter of the pores on the porous membrane The average pore diameter is 500nm). A housing is used in cooperation with the membrane tube, the space formed by the outer wall of the membrane tube and the inner wall of the housing is used as the first channel, and the channel on the membrane tube is used as the second channel, and the first channe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com