Method for preparing ultrafine-yttria stable zirconia powder

A technology for stabilizing zirconia and yttrium oxide, which is applied in the field of high-temperature structural ceramic material preparation to achieve the effects of uniform powder particle size, good crystallinity and good sintering performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Preparation of ultrafine yttria stabilized zirconia powder

[0040] (1) First prepare ZrOCl with a concentration of 0.4mol / L with deionized water 2 solution and a 0.2mol / L yttrium nitrate solution. Measure the prepared ZrOCl 2 Solution 200ml, Y(NO 3 ) 3 Solution 21ml, 2ml CE64 solution, adjust the pH value to 7 with ammonia water, stir thoroughly for half an hour and heat at 100°C for 24h to obtain a white precursor;

[0041] (2) Put the obtained white precursor into a reaction kettle at 150°C for 24 hours to obtain a white precipitate of crystallinity; wash the white precipitate repeatedly with deionized water and filter it until there is no Cl in the white precipitate - Finally, wash twice with absolute ethanol and filter with suction, this purpose is to reduce the agglomeration between powders;

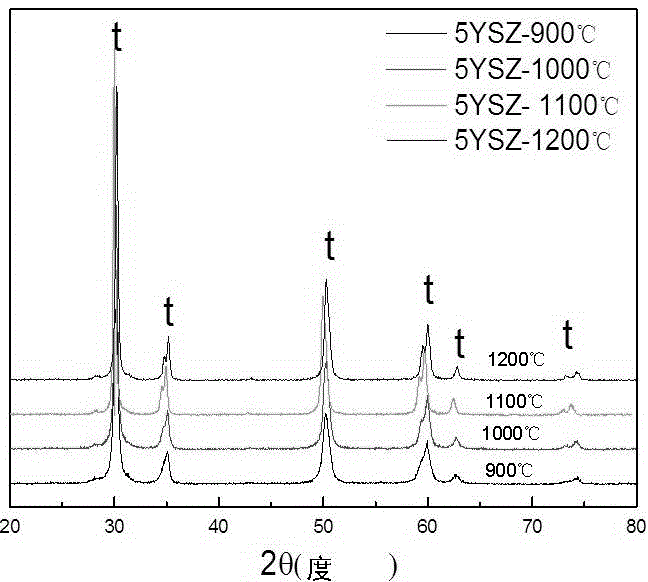

[0042] (3) Calcinate the washed white precipitate at 900°C, 1000°C, 1100°C and 1200°C for 2 hours to obtain 5mol% Y 2 o 3 -ZrO 2 powder.

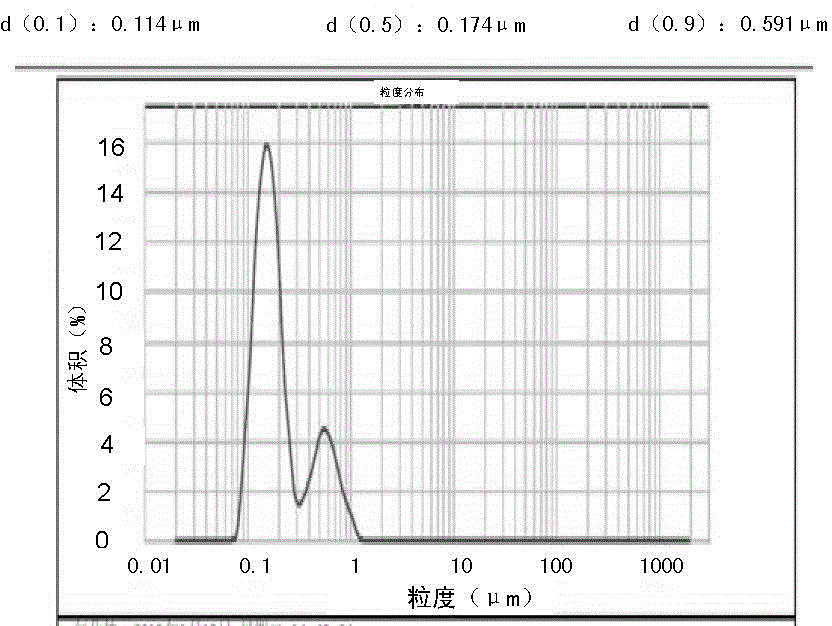

[0043] Characterization m...

Embodiment 2

[0049] (1) First prepare ZrOCl with a concentration of 0.4mol / L with deionized water 2 solution and a 0.2mol / L yttrium nitrate solution. Measure the prepared ZrOCl 2 Solution 200ml, Y(NO 3 ) 3 Solution 38ml, 2ml CE64 solution, adjust the pH value to 7 with ammonia water, stir thoroughly for half an hour and heat at 100°C for 24h to obtain a white precursor;

[0050] (2) Put the obtained white precursor into a reaction kettle at 150°C for 24 hours to obtain a white precipitate of crystallinity; wash the white precipitate repeatedly with deionized water and filter it until there is no Cl in the white precipitate - Finally, wash twice with absolute ethanol and filter with suction, this purpose is to reduce the agglomeration between powders;

[0051] (3) Calcinate the washed white precipitate at 900°C, 1000°C, 1100°C and 1200°C for 2 hours to obtain 8mol% Y 2 o 3 -ZrO 2 powder.

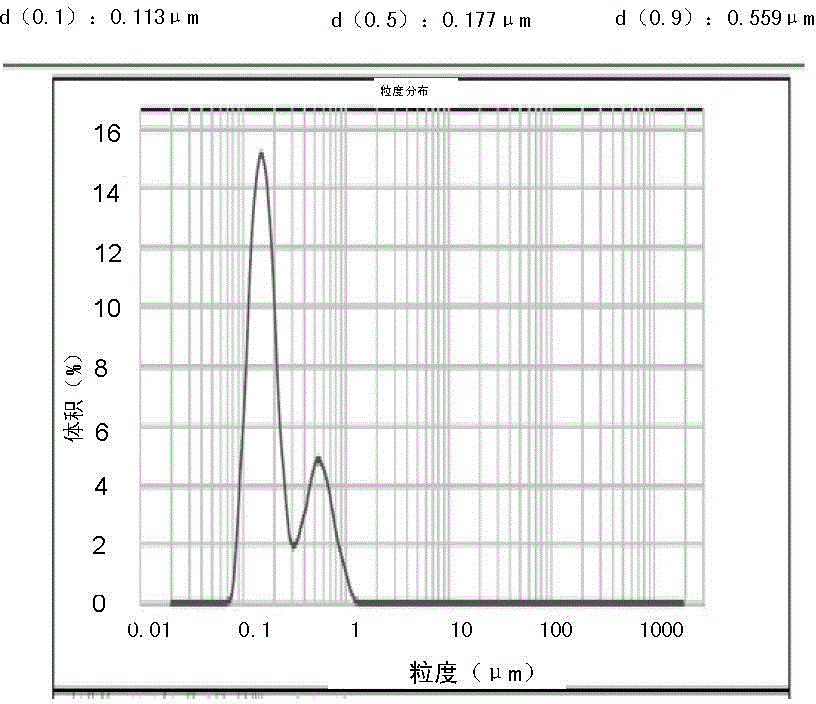

[0052] Laser particle size: The secondary particle size of the powder prepared in this experim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com