A kind of preparation method of phase stable ammonium nitrate

A technology of ammonium nitrate and phase stabilization, applied in the direction of non-explosive stabilizers, offensive equipment, non-explosive/non-thermal agent components, etc., can solve the problems of toxicity and restricted use, and achieve the effect of inhibiting the phase transition of ammonium nitrate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

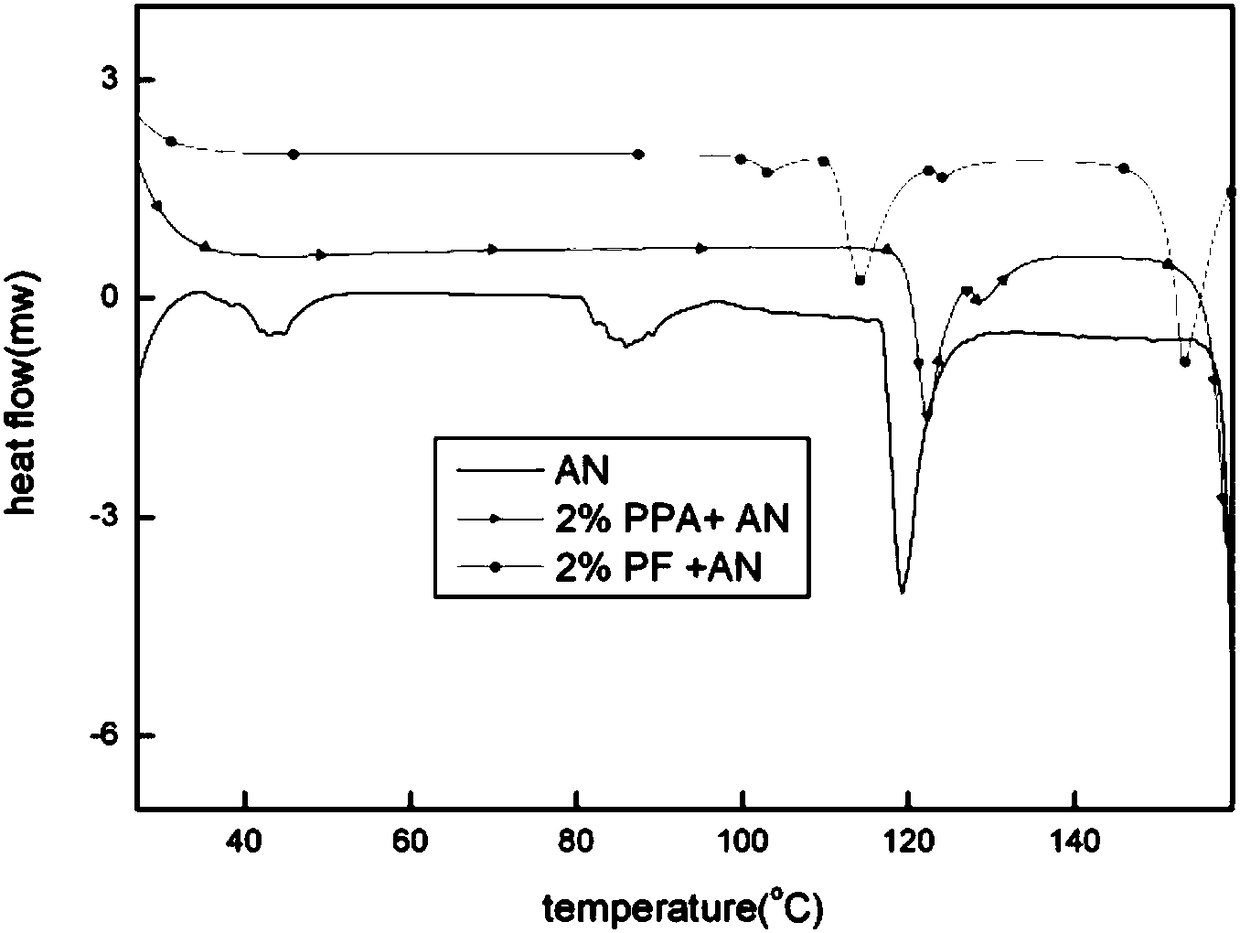

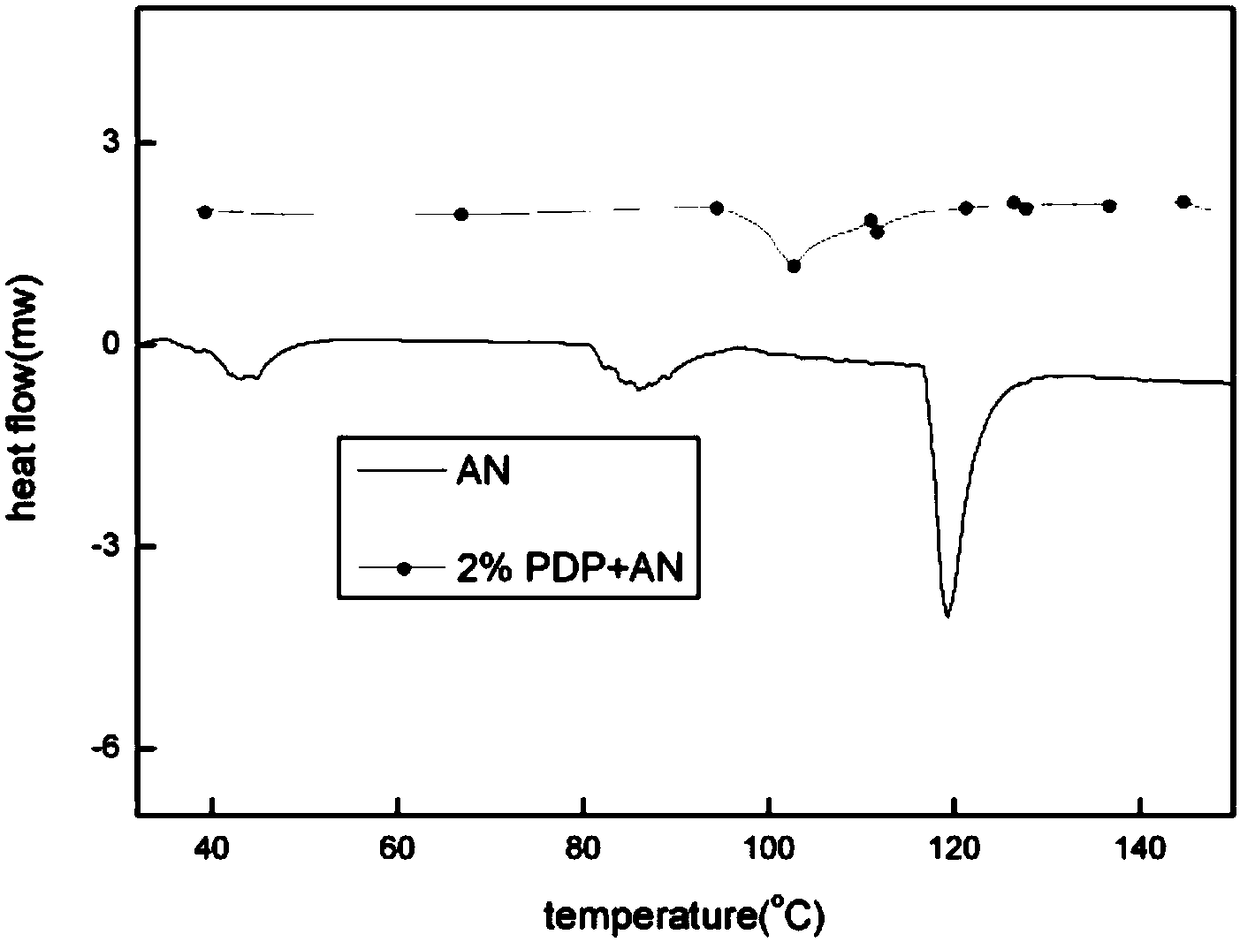

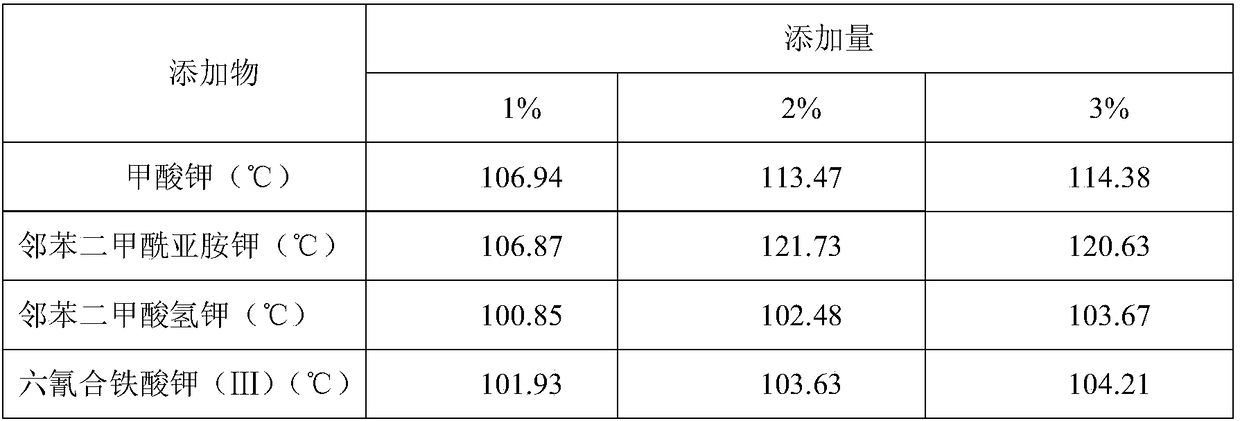

[0018] Dry, grind and grind 98g of ammonium nitrate and dissolve it in 25g of deionized water, then add 2g of potassium formate (PF), heat and stir at 100°C, the mixture is completely dissolved and then naturally cool to room temperature, after recrystallization, filter, and put the filtrate at 60°C Dry for 20 hours to constant weight, grind and sieve (100 mesh) to obtain phase-stable ammonium nitrate. The DSC results of the sample test are shown in Table 1, and the typical test results are shown in figure 1 . Phase stable ammonium nitrate has no phase change in the range of 30°C-100°C.

Embodiment 2

[0020] Dry, grind and grind 99g of ammonium nitrate and dissolve it in 70g of isopropanol, then add 1g of potassium formate (PF), heat and stir at 70°C, the mixture is completely dissolved and cooled to room temperature naturally, after recrystallization, filter, and filter the filtrate at 60°C Dry at ℃ for 24 hours to constant weight, grind and sieve (100 mesh) to obtain phase-stable ammonium nitrate. The DSC results of the sample test are shown in Table 1. Phase stable ammonium nitrate has no phase change in the range of 30°C-100°C.

Embodiment 3

[0022] Dry, grind and pulverize 97g of ammonium nitrate and dissolve it in 50g of deionized water, then add 3g of potassium formate (PF), heat and stir at 80°C, the mixture is completely dissolved and then naturally cool to room temperature, after recrystallization, filter, and put the filtrate at 40°C Dry for 40 hours to constant weight, grind and sieve (300 mesh) to obtain phase-stable ammonium nitrate. The DSC results of the sample test are shown in Table 1. Phase stable ammonium nitrate has no phase change in the range of 30°C-100°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com