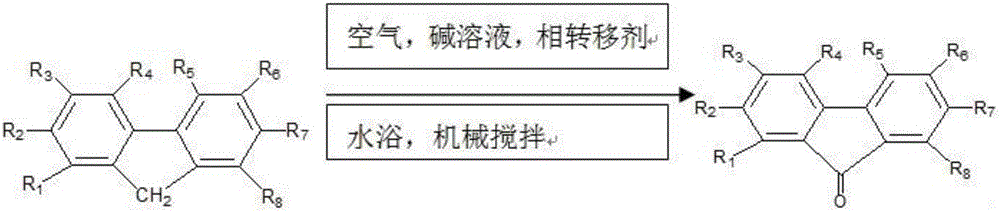

Method for preparing 9-fluorenone with fluorene

A technology of fluorenone and crude fluorene, applied in the field of organic synthesis, can solve the problems that quaternary ammonium salts are easy to decompose and cannot be used in a long-term cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Add 42.00g of industrial fluorene with a mass fraction of 95.44%, 18-crown-63.20g, and 45ml of xylene to a 250ml four-necked flask in sequence, adjust the temperature of the water bath to maintain 50°C, and use α-methylnaphthalene to absorb the solvent entrained in the tail gas , start the mechanical stirring, adjust the stirring rate to 300 rpm, after stirring for 10 minutes, add 6.70g KOH and 10.0ml water. After mixing evenly, start feeding 300mlx2 / min of clean and moist air, record the reaction time, and track the reaction with thin-layer chromatography. After reacting for 10 hours, the spot of fluorene disappeared, and the reaction was continued for 1 hour, and the sample was taken for gas chromatography analysis. Compared with the chromatogram of fluorene raw material, the peak of fluorene was missing, and only the peak of fluorenone was increased. Cool the reaction solution, crystallize the fluorenone, filter the mixture, recover the filtrate for recycling, wash t...

Embodiment 2

[0066]Except replacing 6.7g potassium hydroxide with 8.4g potassium hydroxide, other is the same as embodiment 1. After reacting for 5 hours, thin-layer chromatography showed that the spots of the fluorene raw material disappeared, and the reaction was stopped after continuing the reaction for 1 hour. Chromatographic analysis of the reaction solution showed 100% conversion of fluorene, and only one peak of fluorenone was added. Cool the reaction solution, crystallize the fluorenone, filter the mixture, recover the filtrate for recycling, wash the crystal fluorenone with a small amount of water, and place the crystal in the air to dry naturally. Weighing 30.73g, its purity was 100% by gas chromatography analysis.

Embodiment 3

[0068] Add 45ml of xylene, 62.62g of industrial fluorene, 64.80g of 18-crown-64.80g, 10.0ml of 45wt% KOH solution according to the procedure of Example 1, and the temperature of the water bath is 58°C. After reacting for 7 hours, thin-layer chromatography showed that the spot of fluorene raw material disappeared, and the reaction was stopped after continuing to react for 1 hour. Chromatographic analysis of the reaction solution showed 100% conversion of fluorene, and only one peak of fluorenone was added. Cool the reaction solution, fluorenone crystallizes, filter the mixture, recover the filtrate for use, wash the crystal fluorenone with a small amount of water, and place the crystal in the air to dry naturally. Weighing 50.12g, its purity was 100% by gas chromatography analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com