A kind of high temperature resistant polycarbonate and preparation method thereof

A technology of polycarbonate and high temperature resistance, applied in the field of high temperature resistant polycarbonate and its preparation, to achieve the effect of simple reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

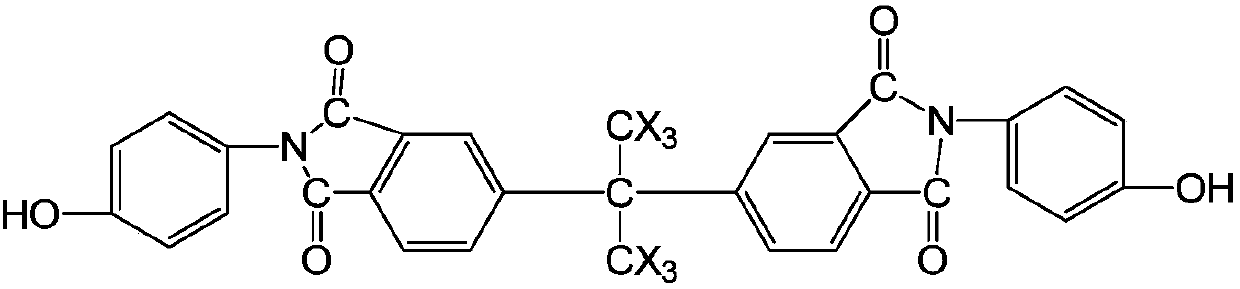

[0031] Synthesis of Dihydric Phenol Monomers Containing Imide Groups

[0032] Add 16.659g (0.0375mol) of 4,4'-(hexafluoroisopropylene) diphthalic anhydride, 8.3045g (0.0750mol) of aminophenol and 100ml of dimethylformamide into the reaction vessel, and stir at room temperature for 3~ 5h, then add 0.15mol acetic anhydride and 0.15mol triethylamine, raise the temperature to 50-60°C, and react for 2-4h; the obtained product is added dropwise to deionized water under stirring condition, then it is suction-filtered, washed and dried Dry, obtain amidation reaction product;

[0033] Add 17.76g (0.0250mmol) of the amidation reaction product into the reaction vessel, add 125ml of methanol and 125ml of chloroform, and add 1.657g of toluenesulfonic acid at the same time, raise the temperature to 75-85°C, and react for 3-5h. Then the temperature was lowered to 35-45° C., and the solvent was removed. Finally, recrystallize in 200 ml of deionized water / dioxane (1:1 volume ratio), wash and...

Embodiment example 1

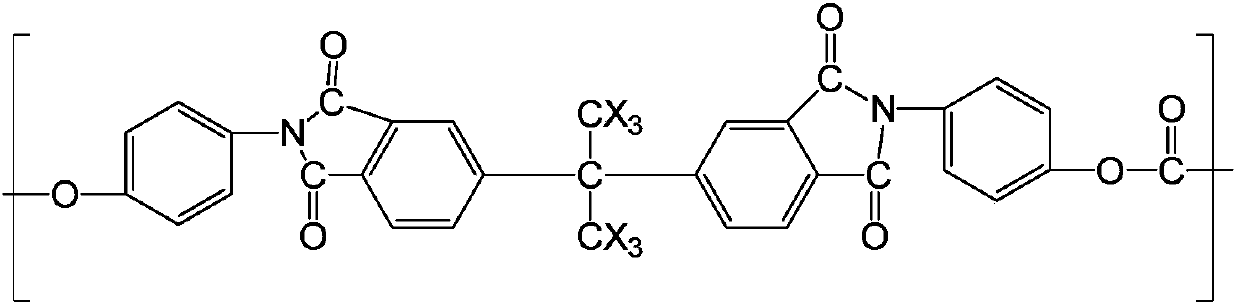

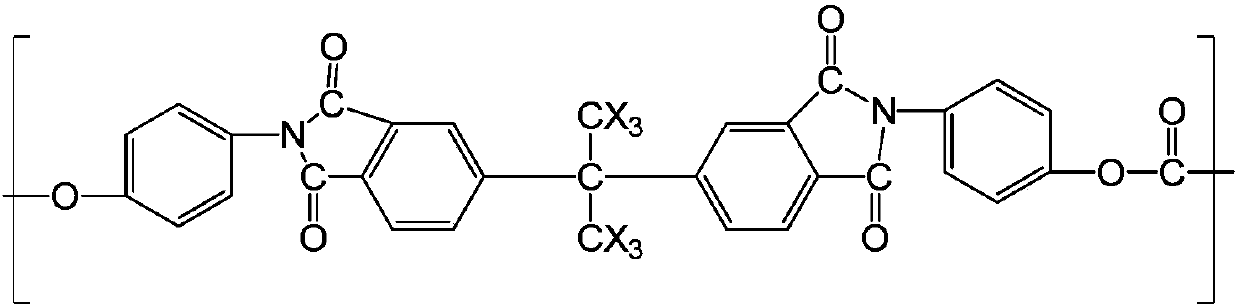

[0036] The molecular structural formula of the polycarbonate prepared by embodiment case 1 is:

[0037]

Embodiment example 2

[0039] Synthesis of Dihydric Phenol Monomers Containing Imide Groups

[0040] Add 12.609g (0.0375mol) of 4,4'-isopropyl diphthalic anhydride, 8.3045g (0.0751mol) of aminophenol and 100ml of dimethylformamide into the reaction vessel, stir at room temperature for 3 to 5 hours, and then Add 0.15mol acetic anhydride and 0.15mol triethylamine, raise the temperature to 50-60°C, and react for 2-4 hours; the obtained product is added dropwise to deionized water under stirring conditions, and then it is suction filtered, washed and dried to obtain Amidation reaction product;

[0041] Add 15.06g (0.25mmol) of the amidation reaction product into the reaction vessel, add 125ml of methanol and 125ml of chloroform, and simultaneously add 1.657g of toluenesulfonic acid, heat up to 75-85°C, and react for 3-5 hours. Then the temperature was lowered to 35-45° C., and the solvent was removed. Finally, recrystallize in 200 ml of deionized water / dioxane (1:1 volume ratio), wash and dry to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com