Flame-retardant high-temperature-resistant boron phenolic resin composition and preparation method thereof

A phenolic resin and composition technology, applied in the field of modified polymer materials and high temperature resistant products, can solve the problems of heat resistance, easy oxidation, etc., and achieve the effects of reducing curing temperature, improving densification, and meeting environmental protection requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with embodiment, but does not limit the present invention.

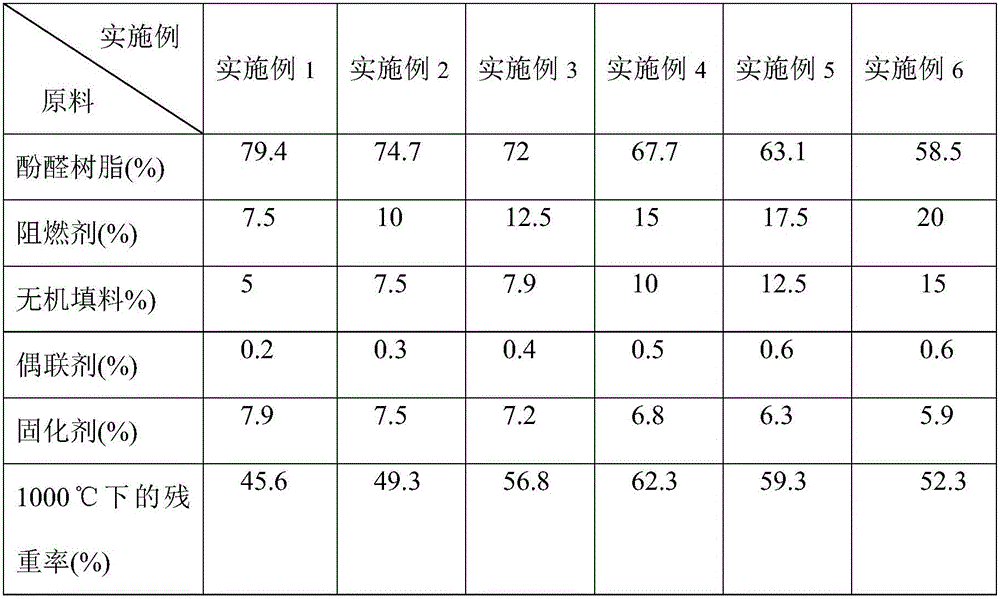

[0021] The flame-retardant and high-temperature-resistant phenolic resin composition provided by the present invention is a phenolic resin composition mainly obtained by adding a flame retardant and an inorganic filler. The composition contains the following components in weight percent: phenolic resin 58.5 to 79.4 %, flame retardant 7.5-20.0%, coupling agent 0.2-0.6%, inorganic filler 5.0-15.0%, curing agent 5.0-10.0%.

[0022] The coupling agents are silane coupling agents KH-550 and KH-570, the mass of which is 5%-12% of the modified substance. The curing agent is hexamethylenetetramine, and the content of the curing agent hexamethylenetetramine is set at 5.0-10%. The curing temperature is 60°C, and the curing time is 12 hours.

[0023] Dissolve the phenolic resin in an appropriate amount of absolute ethanol solution at a temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com