Preparation method of formaldehyde adsorption water-based environmental protection coating

An environmentally friendly coating and formaldehyde adsorption technology, applied in the direction of coating, etc., to achieve the effect of improving comprehensive performance, improving indoor air, and good adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

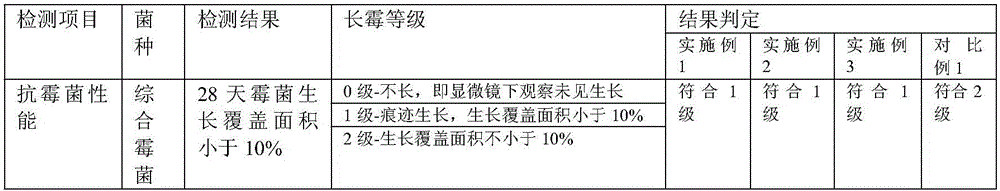

Examples

Embodiment 1

[0027] A formaldehyde-absorbing water-based environmental protection paint, comprising the following raw materials in parts by weight: 20 parts of styrene-acrylate resin liquid; 22 parts of pure acrylic acid emulsion; 13 parts of 2-imidazolidinone; 1-(2-hydroxyethyl)- 8 parts of 2-imidazolidinone; 8 parts of polyether modified polysiloxane; 11 parts of vinyl acetate-ethylene copolymer emulsion; 8 parts of nano-activated carbon; 7 parts of nano-titanium dioxide; 12 parts of calcined kaolin; 9 parts of anion additive; 3 parts; 8 parts of glycerin; 3 parts of hydroxyethyl cellulose; 1 part of cellulose ether; 11 parts of acrylate-styrene-vinyl acetate terpolymer; poly(N-isopropylacrylamide) modified 7 parts of magnesium hydroxide; 70 parts of deionized water.

[0028] Preferably, the liquid-solid content of the styrene-acrylate resin is 37-40wt%.

[0029] Preferably, the particle size of the nano activated carbon is 20-50nm.

[0030] Preferably, the particle size of the nano ti...

Embodiment 2

[0041] A formaldehyde-absorbing water-based environmental protection coating, comprising the following raw materials in parts by weight: 26 parts of styrene-acrylate resin liquid; 17 parts of pure acrylic emulsion; 15 parts of 2-imidazolidinone; 1-(2-hydroxyethyl)- 12 parts of 2-imidazolidinone; 6 parts of polyether modified polysiloxane; 12 parts of vinyl acetate-ethylene copolymer emulsion; 7 parts of nano-activated carbon; 9 parts of nano-titanium dioxide; 14 parts of calcined kaolin; 9 parts of negative ion additives; 6 parts; 6 parts of glycerin; 6 parts of hydroxyethyl cellulose; 2 parts of cellulose ether; 13 parts of acrylate-styrene-vinyl acetate terpolymer; poly(N-isopropylacrylamide) modified 8 parts of magnesium hydroxide; 80 parts of deionized water.

[0042] The preparation method is the same as in Example 1.

Embodiment 3

[0044] A formaldehyde-absorbing water-based environmental protection paint, comprising the following raw materials in parts by weight: 22 parts of styrene-acrylate resin liquid; 20 parts of pure acrylic acid emulsion; 17 parts of 2-imidazolidinone; 1-(2-hydroxyethyl)- 10 parts of 2-imidazolidinone; 5 parts of polyether modified polysiloxane; 13 parts of vinyl acetate-ethylene copolymer emulsion; 5 parts of nano-activated carbon; 9 parts of nano-titanium dioxide; 14 parts of calcined kaolin; 9 parts of negative ion additive; 7 parts; 8 parts of glycerin; 6 parts of hydroxyethyl cellulose; 2 parts of cellulose ether; 15 parts of acrylate-styrene-vinyl acetate terpolymer; poly(N-isopropylacrylamide) modified 11 parts of magnesium hydroxide; 80 parts of deionized water.

[0045] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com