Measuring instrument for film residual stress of flexible transparent substrate

A residual stress, transparent substrate technology, applied in the direction of force/torque/power measuring instruments, measuring devices, instruments, etc., can solve the problems of exceeding the measurement range, low reflectivity, and small curvature radius, so as to increase the measurable range and reduce the Interference effects, effects of consistent relative positions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Embodiments of the present invention are described in detail as follows in conjunction with accompanying drawings:

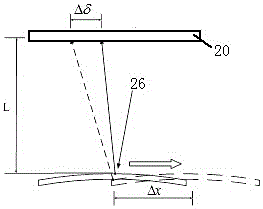

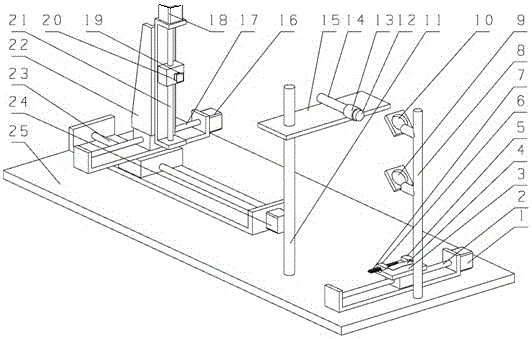

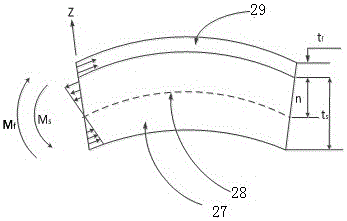

[0028] figure 1 It is the schematic diagram of the single-beam optical lever method, such as figure 1 with figure 2 As shown, the measuring instrument of the residual stress of the film on the flexible transparent substrate of the present invention adopts the principle of the optical lever method to measure the radius of curvature before and after the long film of the substrate, and utilizes the revised Stoney formula to obtain the residual stress; the residual stress of the film on the flexible transparent substrate is The measuring instrument includes an optical platform 25, a first support rod 8, an optical path system, a laser light source system, a sample support system, and a spot tracking three-dimensional motion system; the laser light source system and the optical path system are fixed on the first support rod, and the first The supporting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com