A multi-heat pipe composite high-power electronic chip radiator

An electronic chip and high-power technology, applied in the direction of electric solid-state devices, circuits, electrical components, etc., can solve the problems of heat dissipation performance limitation, limit heat dissipation to be improved, etc., to achieve the goal of increasing the carrying limit, increasing the capillary limit, and meeting the heat dissipation requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing:

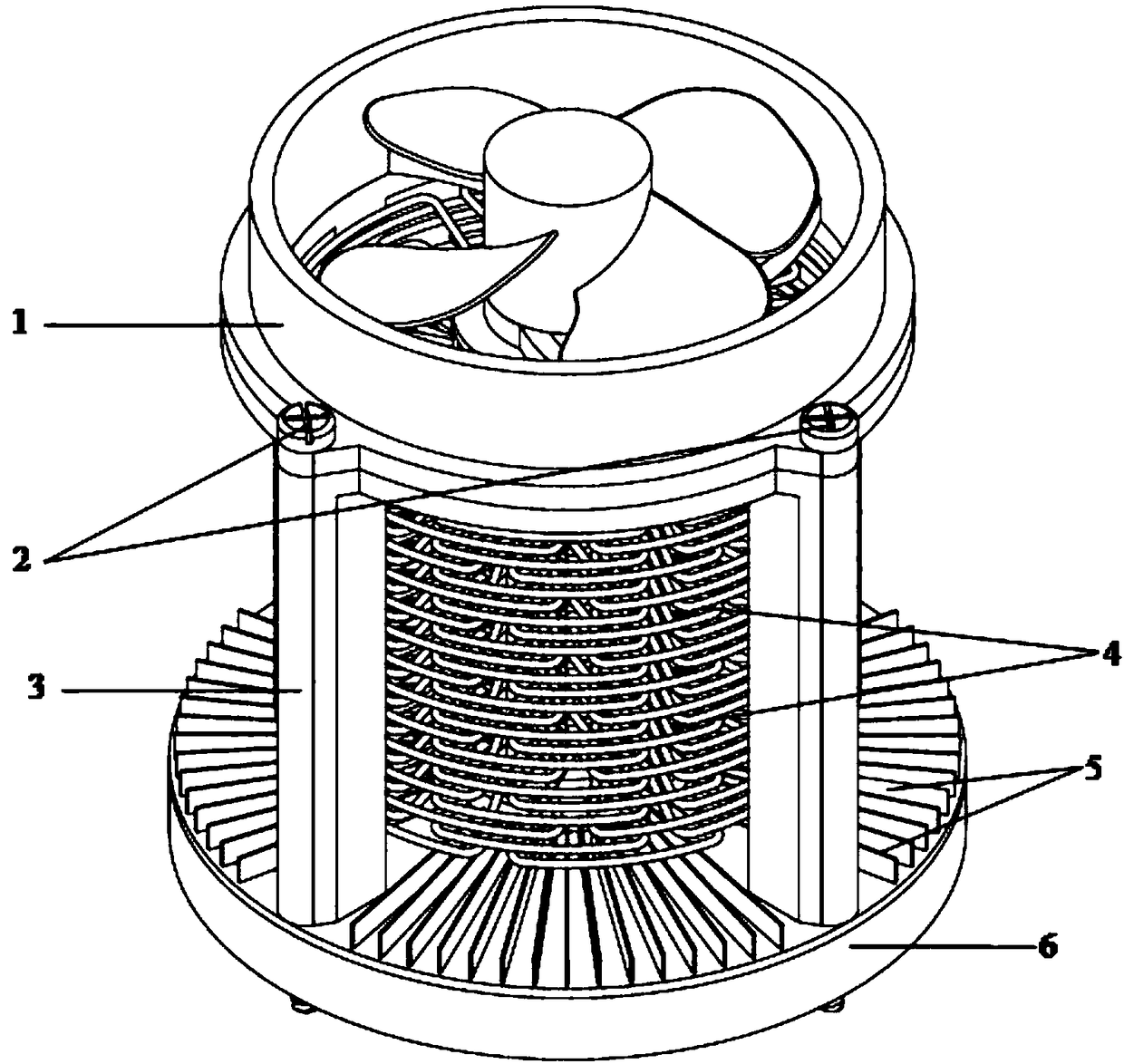

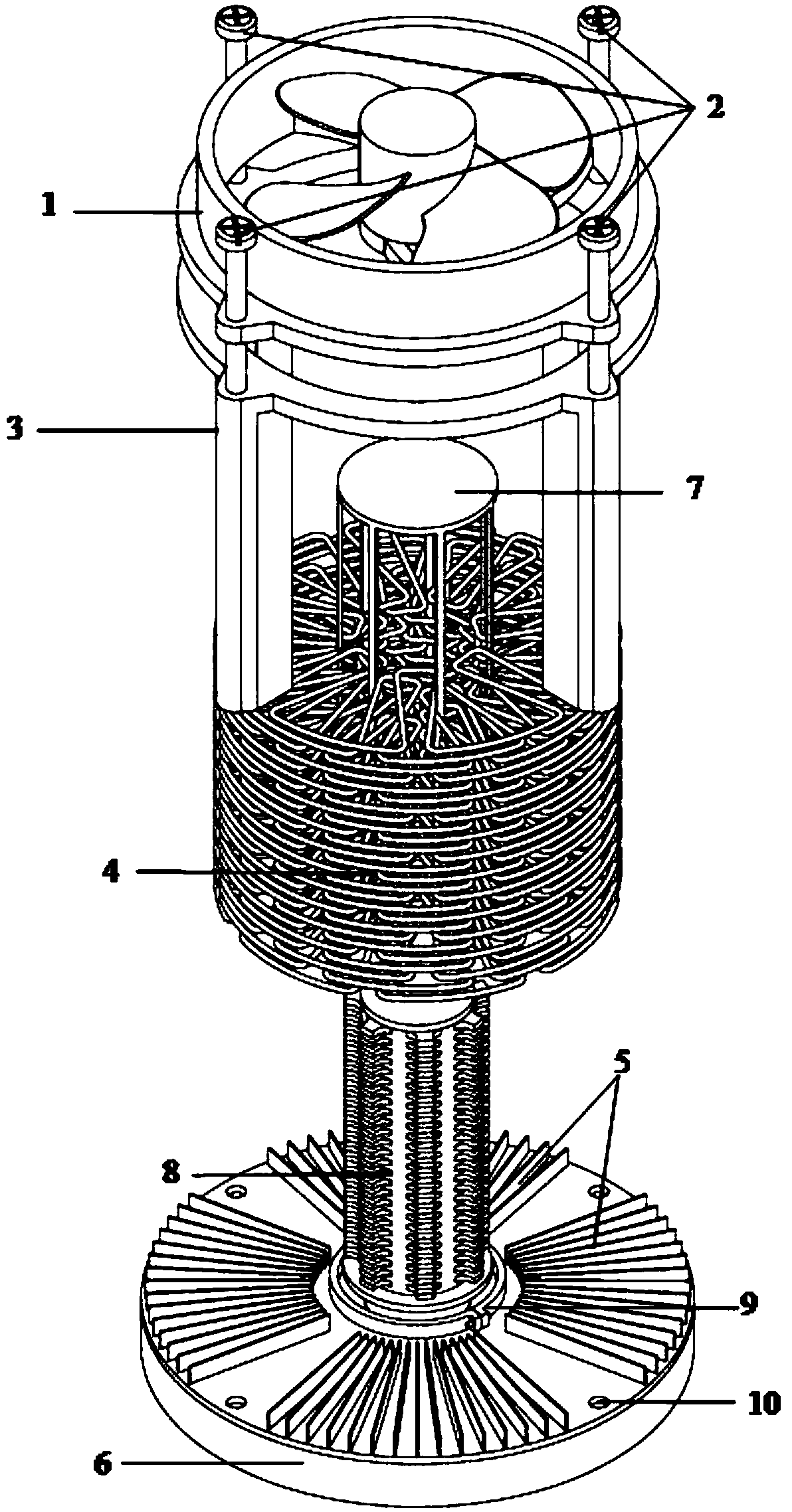

[0029] Such as Figure 1-2 As shown, a multi-heat pipe composite high-power electronic chip radiator includes an annular steam cavity base 6, a gravity heat pipe 8, a heat-driven pulsating flow heat pipe fin 4, a fastening handle 7, a tie hoop 9, and a cooling fan 1. Enclosure bracket 3 and fastening bolt 2.

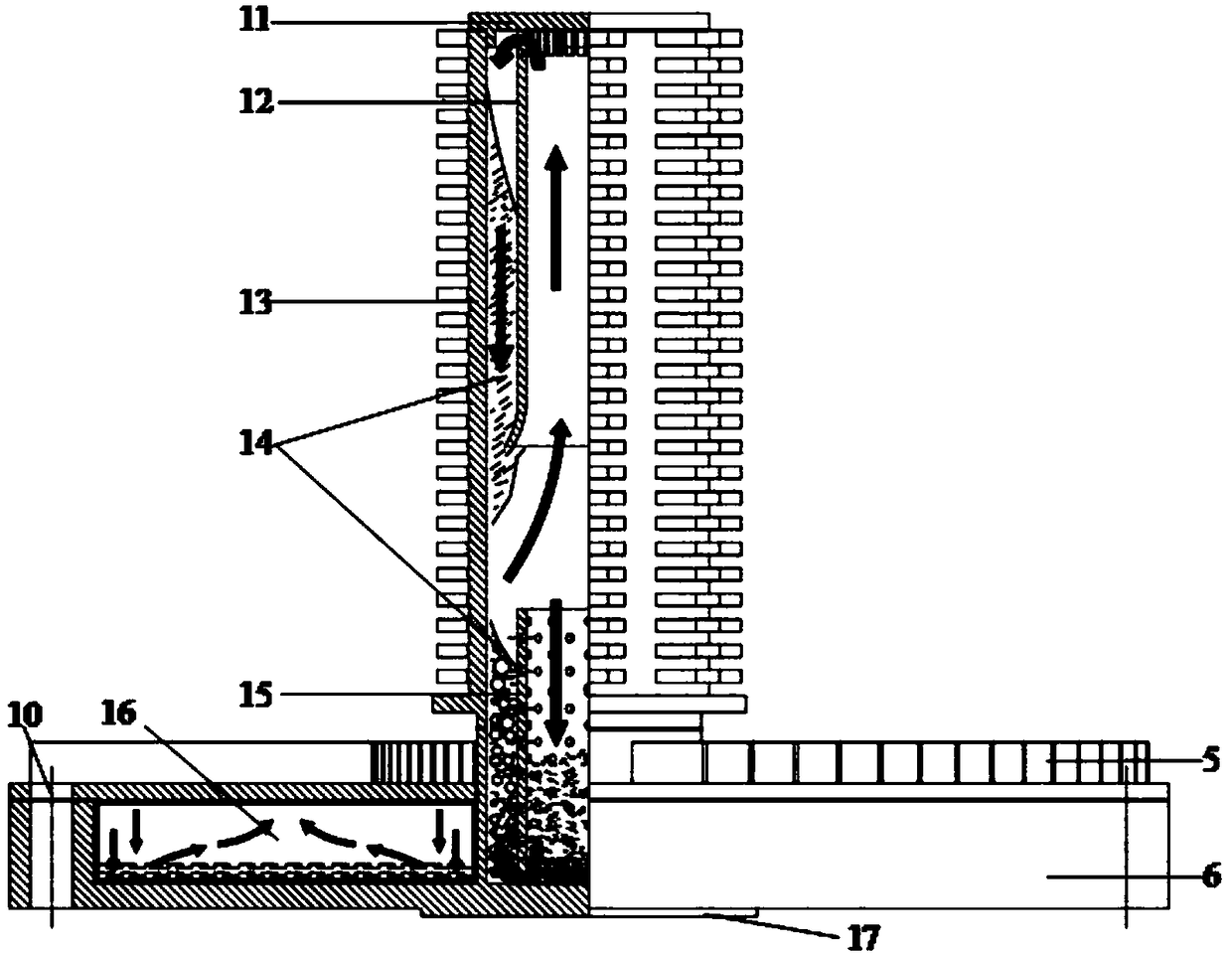

[0030] Such as Figure 3-4 As shown, a multi-heat pipe composite high-power electronic chip radiator, the annular steam chamber base 6 is welded and processed by a combination of a base plate 21 and a cover plate 18, and the materials of each component are high thermal conductivity metals or alloys, such as copper ( alloy), aluminum (alloy), nickel (alloy), etc. The substrate 21 is processed with an inner ring opening cavity 19 and an outer ring opening cavity 20, and the back of the inner ring opening cavity 19 is processed with a high-power electronic chip heat-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com