Vulcanization-bonded laminate, and rubber composition for use in same

A technology for rubber and rubber layers, applied in the field of vulcanized adhesive laminates and chloroether rubber compositions, can solve the problems of coexistence of inability to adhere to a high level of operability, and achieve favorable manufacturing costs and long scorch time. , excellent adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

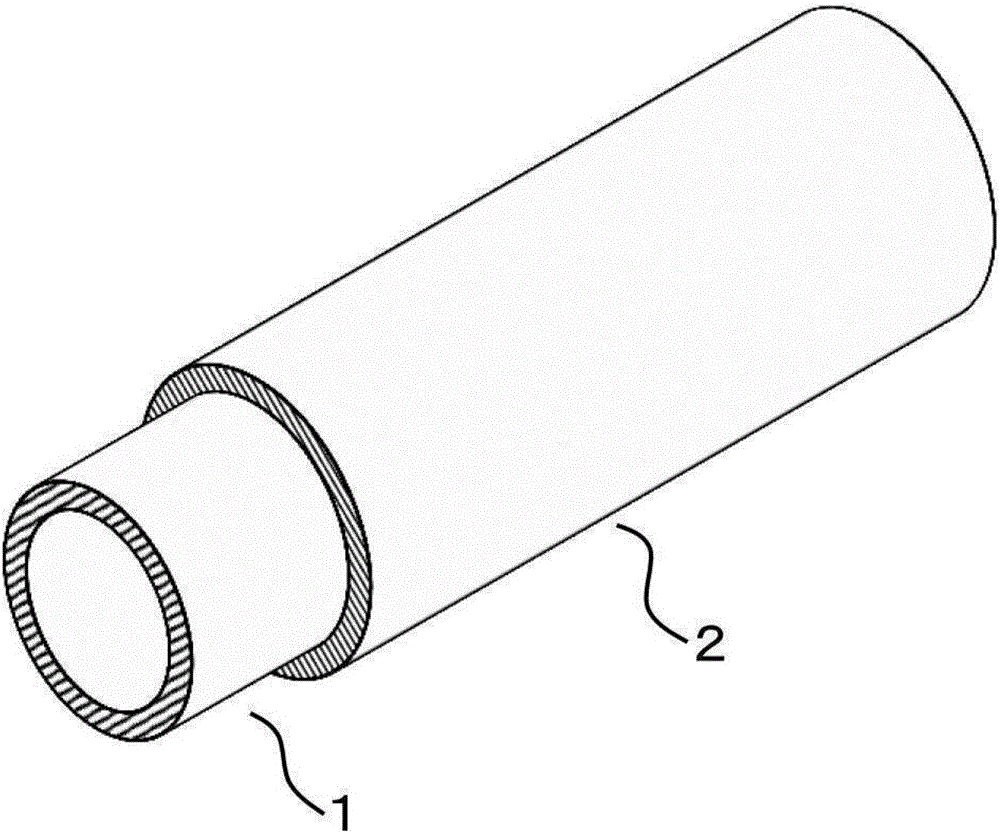

Image

Examples

Embodiment

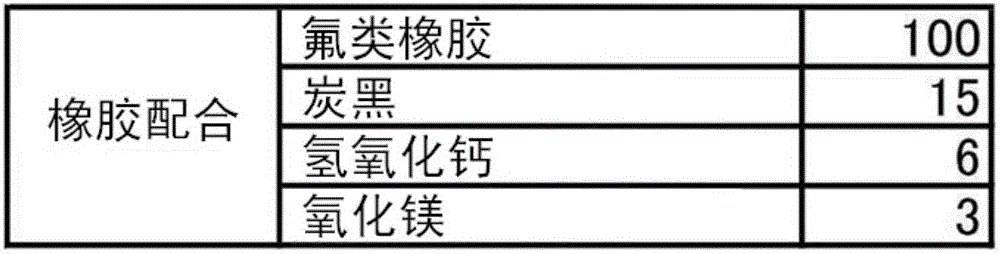

[0073] Each component was blended in the amounts shown in Table 1, and kneaded with a kneader to obtain a fluororubber composition. A fluororubber sheet having a thickness of 2 mm was produced from the fluororubber composition using an 8-inch roll.

[0074] Table 1

[0075]

[0076] Fluorine rubber: DAI-ELG558 (manufactured by Daikin Industries, Ltd.: polyol vulcanized)

[0077] Carbon black: SEASTS (manufactured by Tokai Carbon Co., Ltd.)

[0078] Calcium hydroxide: CALDIC#2000 (manufactured by Ohmi Chemical Industry Co., Ltd.)

[0079] Magnesium oxide: MgO#150 (manufactured by Kyowa Chemical Industry Co., Ltd.)

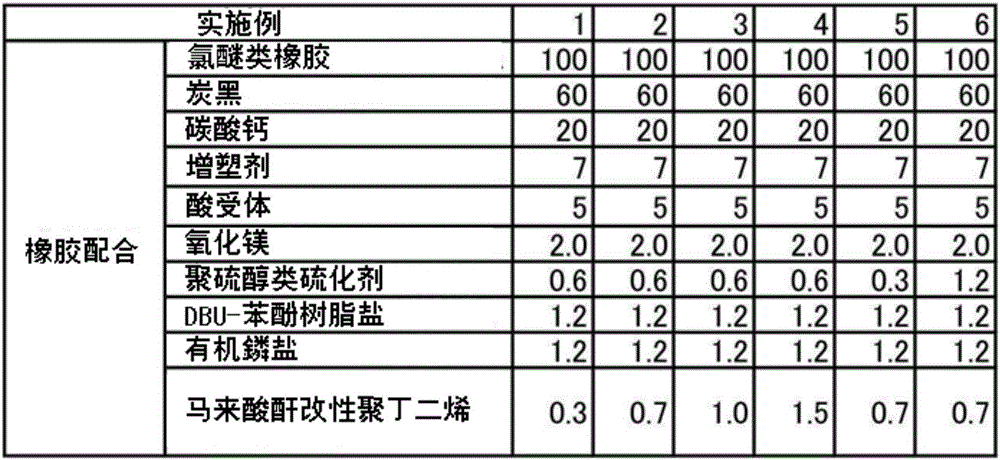

[0080] Each component was blended in the amounts shown in Tables 2 and 3, and kneaded with a kneader to obtain a chloroether-based rubber composition. A chloroether-based rubber sheet having a thickness of 2 mm was produced from the chloroether-based rubber composition using an 8-inch roll.

[0081] Table 2

[0082]

[0083] table 3

[0084]

[0085]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com