Preparation method of CNT-modified nanofiltration membrane

A nanofiltration membrane and modification technology, which is applied in the field of nanofiltration membranes, can solve the problems of low water flux and retention rate, and achieve the effects of improving hydrophilic performance, enhancing hydrophilicity, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

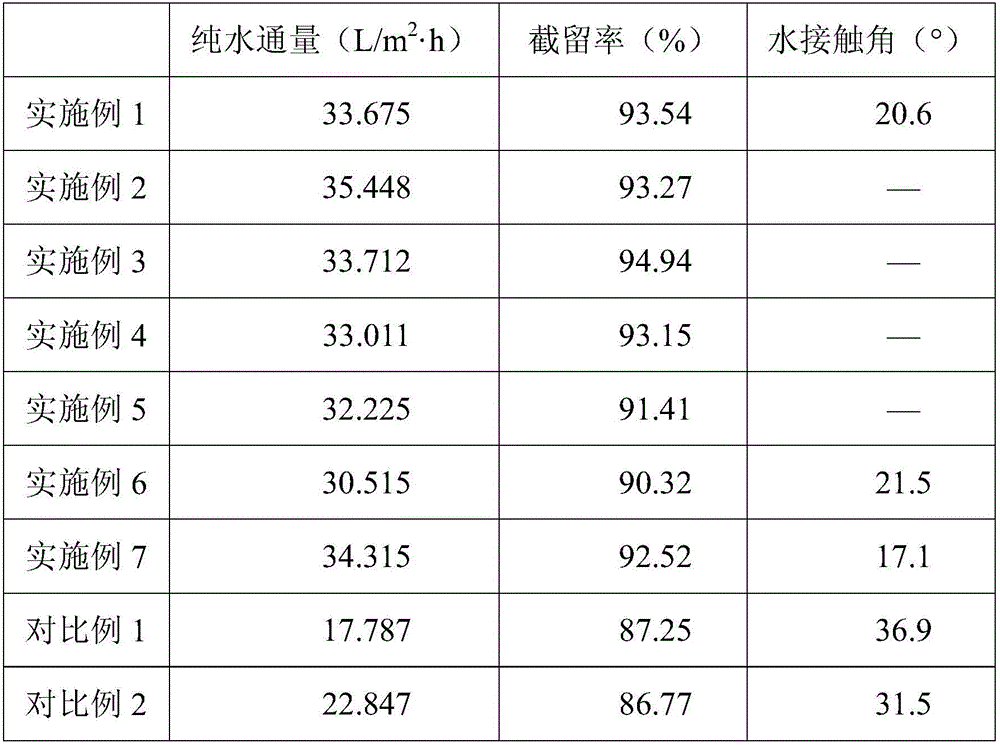

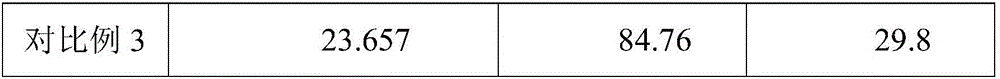

Examples

Embodiment 1

[0028] The preparation method of the CNT modified nanofiltration membrane described in this embodiment comprises the following steps:

[0029] (1) Add anhydrous sodium phosphate, anhydrous piperazine and CNT dispersion liquid successively to a certain amount of deionized water, stir to make it dissolve completely and form an aqueous phase solution, which contains 1wt% sodium phosphate, 1wt% Piperazine, 3wt% CNT dispersion and 95wt% water, wherein, CNT accounts for 0.1wt% in the CNT dispersion, and the balance is deionized water;

[0030] (2) dissolving trimesoyl chloride in n-hexane to form an organic phase solution in which trimesoyl chloride accounts for 0.15 wt %;

[0031] (3) Fix the polysulfone ultrafiltration membrane on the corrosion-resistant polyethylene splint, pour the aqueous phase solution of step (1) into the surface of the membrane surface A on one side of the membrane, and make the aqueous phase solution covered with Membrane surface A, after keeping for 120s,...

Embodiment 2

[0034] The preparation method of the CNT modified nanofiltration membrane described in this embodiment comprises the following steps:

[0035] (1) Add anhydrous sodium phosphate, anhydrous piperazine and CNT dispersion liquid successively to a certain amount of deionized water, stir to make it dissolve completely to form water phase solution, contain the sodium phosphate of 1.5wt%, 0.5% in this water phase solution wt% piperazine, 3wt% CNT dispersion and 95wt% water, wherein CNT accounts for 0.1wt% in the CNT dispersion, and the balance is dimethylformamide;

[0036] (2) dissolving trimesoyl chloride in n-hexane to form an organic phase solution in which trimesoyl chloride accounts for 0.25 wt %;

[0037] (3) Fix the polysulfone ultrafiltration membrane on the corrosion-resistant polyethylene splint, pour the aqueous phase solution of step (1) into the surface of the membrane surface A on one side of the membrane, and make the aqueous phase solution covered with Membrane surf...

Embodiment 3

[0040] The preparation method of the CNT modified nanofiltration membrane described in this embodiment comprises the following steps:

[0041](1) Add anhydrous sodium phosphate, anhydrous piperazine and CNT dispersion liquid successively to a certain amount of deionized water, stir to make it dissolve completely and form an aqueous phase solution, containing 1.5wt% sodium phosphate, 1wt% in this aqueous phase solution % piperazine, 2.5wt% CNT dispersion and 95wt% water, wherein CNT accounts for 0.1wt% in the CNT dispersion, and the balance is ethanol;

[0042] (2) dissolving trimesoyl chloride in n-hexane to form an organic phase solution in which trimesoyl chloride accounts for 0.3 wt %;

[0043] (3) Fix the polysulfone ultrafiltration membrane on the corrosion-resistant polyethylene splint, pour the aqueous phase solution of step (1) into the surface of the membrane surface A on one side of the membrane, and make the aqueous phase solution covered with Membrane surface A, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com