Nanopowder Preparation Device by Confined Electroexplosion Method of Ablation Material Tube

An electric explosion device and nano-powder technology, which is applied in the direction of nanotechnology, can solve the problems of unsatisfactory synthesis of electric explosive materials, reduction of energy density of powder conductors, energy reduction, etc., and achieve reliable conductivity, high pressure, and electric current. The continuous effect of the explosion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

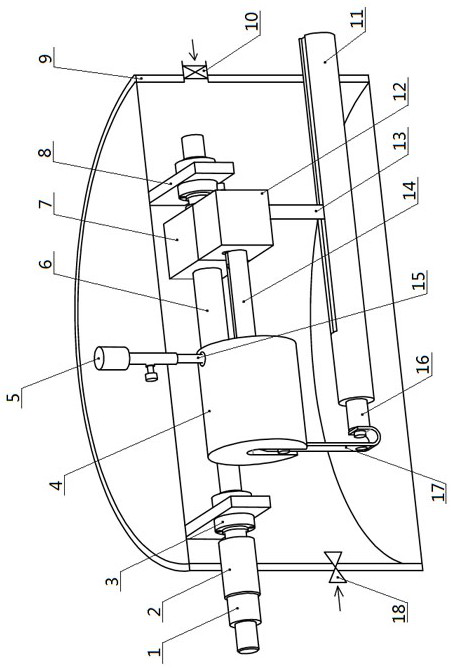

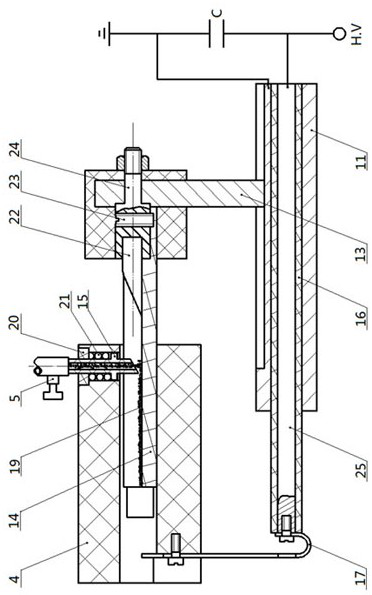

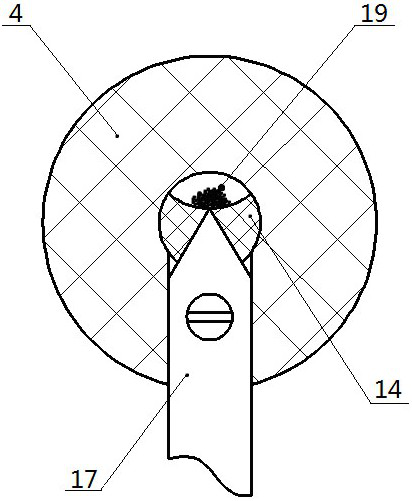

[0009] like figure 1 , figure 2 , image 3 As shown, the present invention is a device for preparing nanopowder by ablation material tube-constrained electric explosion method, including an electric explosion chamber and an electric explosion device, wherein the electric explosion device includes a driving mechanism, a feeding mechanism, and an explosion mechanism, and the electric motor 1 passes through a dynamic sealing mechanism 2 Installed outside the electric explosion chamber 9, the reciprocating lead screw 6 is installed in the electric explosion chamber 9 through the bearing housing 3 and the support plate 8, and the lead screw nut 7 on the reciprocating lead screw 6 drives the connecting body 12 fixed thereon to make Reciprocating movement, the loading rod 14 is fixed together with the electrode holder 24 by the screw 23 and then installed in the connecting body 12; the material guide tube 15 extends into the constraint sleeve 4, and the boss on the material guide t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com