Biocompatible phosphate based continuous glass fiber and fabric prepared from same

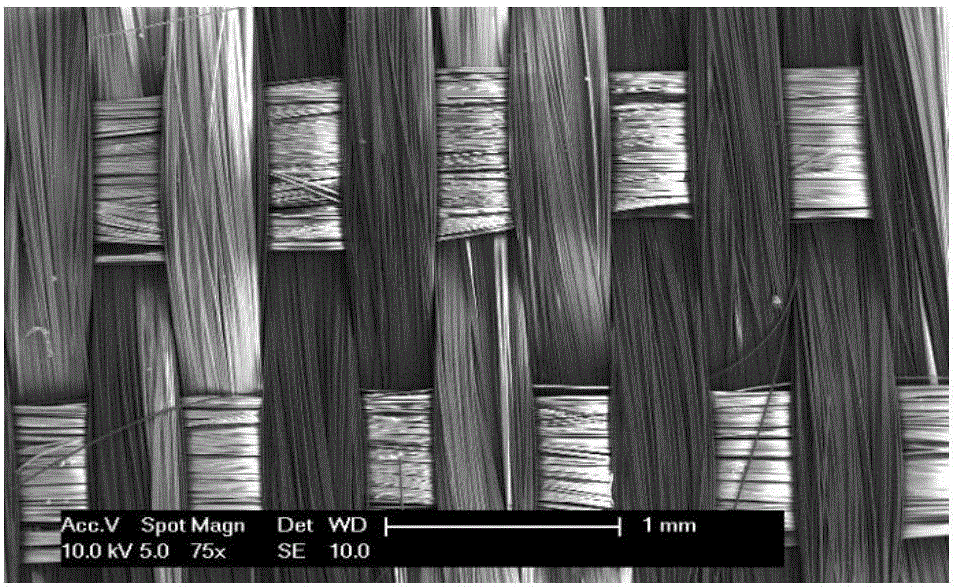

A technology of glass fiber and phosphate, which is applied in the field of biomedical materials, can solve the problems that the monofilament product form cannot be processed for textile processing, and the compounding of degradable polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation method of each embodiment phosphate glass fiber:

[0063] (1) Batch preparation

[0064] Mix the raw materials containing the above components according to the formula. In the formula, MgO, Na 2 O, K 2 O, Fe 2 o 3 , CaO and other phosphates with corresponding substances are introduced, B 2 o 3 by H 3 BO 3 introduced, and the rest of P by P 2 o 5 introduce.

[0065] (2) batch material processing

[0066] due to P 2 o 5 Absorb moisture and release a lot of heat at the same time. After the batch is weighed, wait for the moisture absorption reaction of the batch to complete in the fume hood. Before the reaction starts, spray 3% of the total amount of the batch with secondary water.

[0067] (3) Glass melting

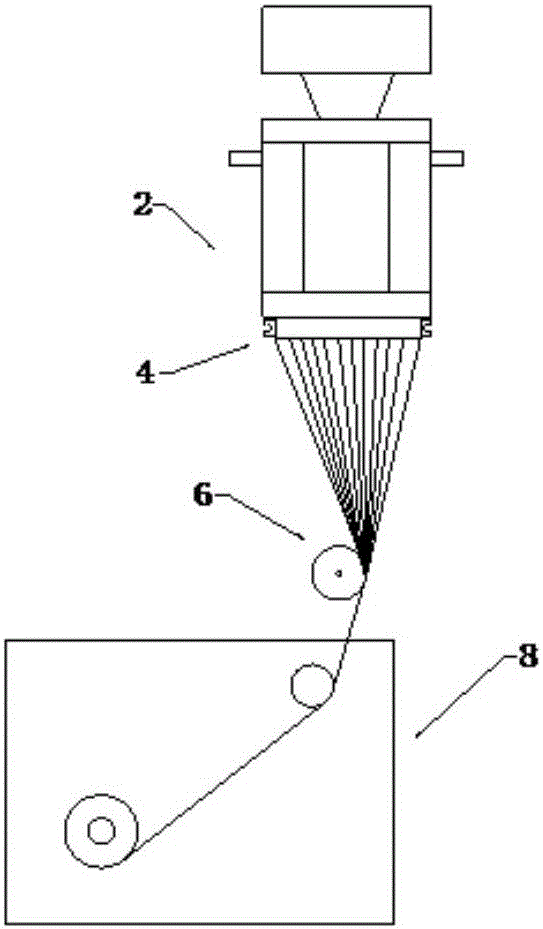

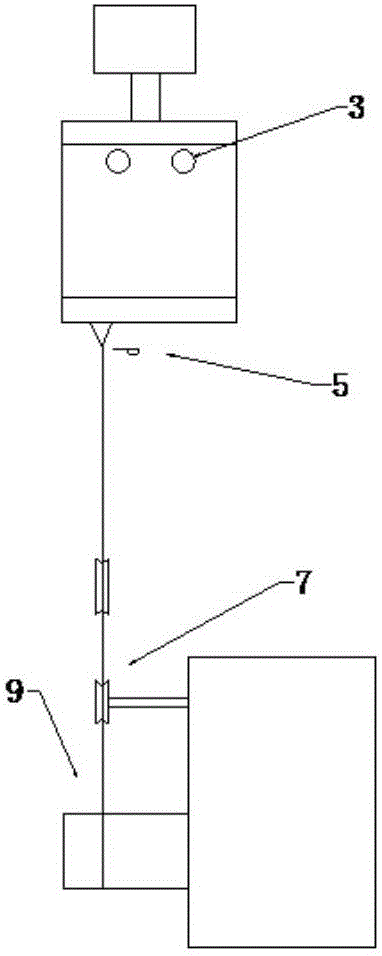

[0068] The phosphate glass batch is continuously fed into the glass melting furnace 2 by an automatic feeder. It is used as a radiation heating device 3 to initially melt the batch material, and then use the glass itself as a resistance ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Modulus | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

| Linear density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com