Preparation method of polybutylcyanoacrylate nanowire

A technology of n-butyl cyanoacrylate and nanowires, which is applied in the field of biological carrier preparation, can solve the problems of harsh preparation process conditions, difficulty in controlling the size of nanowires, and the production of toxic and harmful substances, and achieve low requirements for reaction conditions and biological Compatibility, non-toxic and side effects, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

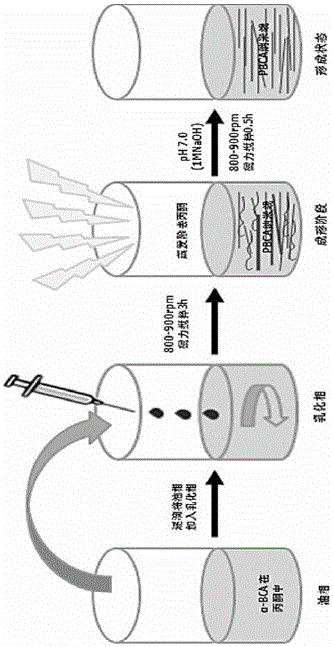

[0032] like figure 1 As shown, a method for preparing poly(n-butyl cyanoacrylate) nanowires provided by this embodiment includes the following steps:

[0033] Prepare the oil phase mixture: Disperse 10 microliters of n-butyl alpha-cyanoacrylate and 0.15 milliliters of ethyl acetate in 5 milliliters of acetone.

[0034] Prepare the emulsified phase mixture: Disperse 25 mg of emulsifier and 50 mg of stabilizer in 5 ml of pure water, the emulsifier is sodium lauryl sulfate, and the stabilizer is dextran-70; The pH was adjusted to 2.5 with 1M hydrochloric acid.

[0035] Interfacial emulsification polymerization: under room temperature, drop the prepared oil phase mixture into the prepared emulsified phase mixture dropwise within 15 to 20 minutes for interfacial emulsification polymerization. Magnetic stirring was performed at a rotating speed of 10 minutes, and the total time of the interfacial emulsification polymerization reaction was 2.5 to 3.5 hours.

[0036] Then the organ...

specific Embodiment 2

[0037] In a kind of preparation method of poly(n-butyl cyanoacrylate) nanowires provided by this implementation:

[0038] Prepare the oil phase mixture: Disperse 10 microliters of n-butyl alpha-cyanoacrylate and 0.15 milliliters of ethyl acetate in 5 milliliters of acetone.

[0039] Prepare the emulsified phase mixture: Disperse 25 mg of emulsifier and 50 mg of stabilizer in 5 ml of pure water, the emulsifier is sodium lauryl sulfate, and the stabilizer is dextran-70; The pH was adjusted to 2.5 with 1M hydrochloric acid.

[0040] The rest of the steps are the same as in the specific embodiment 1.

specific Embodiment 3

[0041] In a kind of preparation method of poly(n-butyl cyanoacrylate) nanowires provided by this implementation:

[0042] Prepare the oil phase mixture: Disperse 10 microliters of n-butyl alpha-cyanoacrylate and 0.20 milliliters of ethyl acetate in 5 milliliters of acetone.

[0043] Prepare the emulsified phase mixture: Disperse 30 mg of emulsifier and 45 mg of stabilizer in 5 ml of pure water, the emulsifier is sodium lauryl sulfate, and the stabilizer is dextran-70; The pH was adjusted to 2.5 with 1M hydrochloric acid.

[0044] The rest of the steps are the same as in the specific embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com