High-temperature-resistant anti-corrosion and anti-radiation coating and preparation method thereof

A technology of anti-radiation coatings and high temperature resistance, applied in anti-corrosion coatings, fire-proof coatings, coatings, etc., can solve problems such as insufficient adhesion, insufficient functions, and few applications, and achieve excellent anti-corrosion, easy implementation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

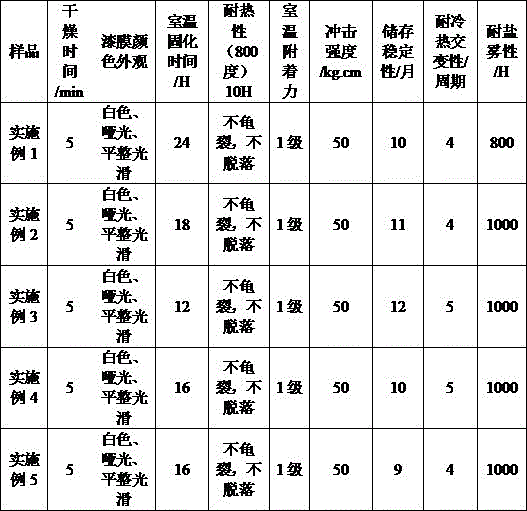

Examples

Embodiment 1

[0019] Embodiment 1 of the present invention provides a high-temperature-resistant anti-corrosion and radiation-proof coating, which includes the following raw materials in parts by weight: 8 parts of aluminum sol, 10 parts of expanded graphite, 5 parts of carbon nanotubes, 1 part of titanium dioxide, and hydroxypropyl methylcellulose 0.5 parts of plain powder, 8 parts of glass powder, 5 parts of talcum powder, 20 parts of mica powder, 1 part of biscyclopentenyloxyethyl acrylate and 20 parts of water, wherein, each raw material in this embodiment is industrial grade.

[0020] Preparation method: Under the condition of 40°C, uniformly mix aluminum sol, expanded graphite and water to form the first mixed solution; add glass powder, talc powder and mica powder to the first mixed solution, and ultrasonically disperse for 30 Minutes to obtain the second mixed solution; carbon nanotubes, titanium dioxide, hydroxypropyl methylcellulose and biscyclopentenyloxyethyl acrylate were added ...

Embodiment 2

[0022] Embodiment 2 of the present invention provides a high-temperature-resistant anti-corrosion and radiation-proof coating, which includes the following raw materials in parts by weight: 9 parts of aluminum sol, 12 parts of expanded graphite, 7 parts of carbon nanotubes, 2 parts of titanium dioxide, and hydroxypropyl methylcellulose 1 part of plain powder, 10 parts of glass powder, 7 parts of talcum powder, 22 parts of mica powder, 2 parts of biscyclopentenyloxyethyl acrylate and 23 parts of water, wherein, each raw material in this embodiment is industrial grade.

[0023] Preparation method: Under the condition of 50°C, uniformly mix aluminum sol, expanded graphite and water to form the first mixed solution; add glass powder, talc powder and mica powder to the first mixed solution, and ultrasonically disperse for 30 minutes to obtain the second mixed solution; carbon nanotubes, titanium dioxide, hydroxypropyl methylcellulose and biscyclopentenyloxyethyl acrylate were respec...

Embodiment 3

[0025] Embodiment 3 of the present invention provides a high-temperature-resistant anti-corrosion and radiation-proof coating, which includes the following raw materials in parts by weight: 10 parts of aluminum sol, 13 parts of expanded graphite, 8 parts of carbon nanotubes, 3 parts of titanium dioxide, and hydroxypropyl methyl cellulose 1.5 parts of plain powder, 11 parts of glass powder, 8 parts of talcum powder, 23 parts of mica powder, 2 parts of dicyclopentenyloxyethyl acrylate and 25 parts of water, wherein, each raw material in this embodiment is industrial grade.

[0026] Preparation method: Under the condition of 60°C, uniformly mix aluminum sol, expanded graphite and water to form the first mixed solution; add glass powder, mica powder and talc powder to the first mixed solution, and ultrasonically disperse for 35 Minutes to obtain the second mixed solution; carbon nanotubes, titanium dioxide, hydroxypropyl methylcellulose and biscyclopentenyloxyethyl acrylate were ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com