Steelmaking process for large-scale customized production

A technology of technology and production planning, applied in the direction of steel manufacturing technology, sustainable manufacturing/processing, metal processing, etc., can solve the problems of restricting product diversification of enterprises, difficult production scheduling, and difficult to realize customized production, so as to achieve flexible production Scheduling, the effect of shortening the lead time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

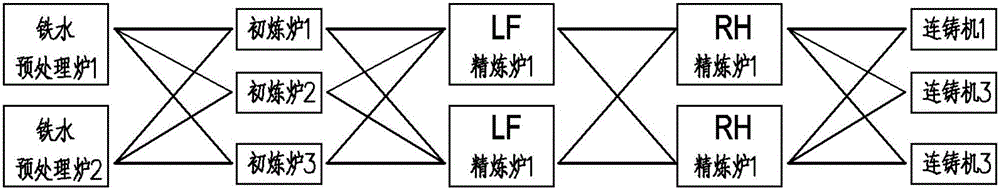

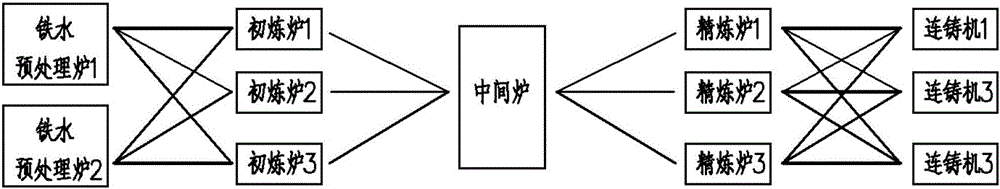

[0019] Such as figure 2 As shown, the present invention is a large-scale custom-made steelmaking process, which uses equipment including two sets of molten iron pretreatment devices, three sets of primary smelting furnaces as converters, one set of intermediate furnaces, and three sets of refining furnaces as RH furnaces. The molten steel is supplied to three sets of continuous casting machines. The steelmaking process of the present invention is characterized in that: the molten steel is transferred from the three primary furnaces to the intermediate furnace for thermal insulation storage and uniform composition according to the basically consistent composition and temperature, and then loaded according to the customized demand. into three refining furnaces, and then into three different continuous casting machines for casting after adjusting the composition.

[0020] The specific process flow is as follows: after two sets of molten iron pretreatment devices successively rec...

Embodiment 2

[0023] A steel group owns carbon structural steel hot-rolled thick steel plate, low-alloy structural steel hot-rolled thick steel plate, ship hull structural steel plate, pressure vessel steel plate, boiler steel plate, bridge structural steel plate, building structure steel plate, low carbon steel hot Rolled round wire rods, high-quality carbon steel hot-rolled wire rods, steel strands for prestressed concrete, seamless steel pipes for high-pressure boilers, etc. have more than 800 varieties and more than 3,000 specifications of products. 4.5 million tons of qualified slabs, with 2 KR desulfurization stations, 2 210t converters, 2 online CAS stations, 2 double-station LF furnaces, 1 double-station RH, 1 double-station VD, 2-stream slabs 3 continuous casting machines. The transformation of steelmaking equipment is as follows: stop using the online CAS station, dismantle one LF furnace, and build a new 600t intermediate furnace at the original site. The steelmaking process is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com