Separation and purification method for metallic sodium

A technology for separation and purification of sodium metal, applied in the direction of improving process efficiency, etc., can solve the problems of high equipment investment, long time consumption, high vacuum degree requirements, etc., achieve high separation and purification efficiency, improve separation and purification efficiency, and excellent economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for separating and purifying metallic sodium, comprising the following steps:

[0034] A 1000mL four-neck flask equipped with a thermometer, nitrogen inlet tube, condenser and mechanical stirring was selected as the metal sodium separation device. First use a large flow of nitrogen to purge and replace the air in the reaction bottle. After the replacement is completed, under the condition of controlling the nitrogen flow rate to 25mL / min, add 500ml of toluene as a dispersion medium, and then add 150g of " Sodium slag". Use an oil bath to heat until the toluene refluxes, control the temperature and keep the toluene in a reflux state for 20 minutes, then slowly start stirring, and finally reach 100rpm, continue stirring at 100rpm for 10min, then start to cool down, and adjust the stirring speed to 30rpm, when When the temperature of the material in the reaction flask dropped to 30°C, the stirring was stopped. Under nitrogen protection, use a metal mesh filter w...

Embodiment 2

[0037] As described in Example 1, the difference is that 500 mL of ethylene glycol diethyl ether is used instead of toluene.

[0038] Obtain 101g of metallic sodium on a 2.0mm metal filter, and the purity of metallic sodium is 99.1%. The filter residue was 40.2g, and the residual metal sodium in the filter residue was about 1.1g.

Embodiment 3

[0040] As described in Example 1, except that 500 mL of ethylene glycol dimethyl ether was used instead of toluene.

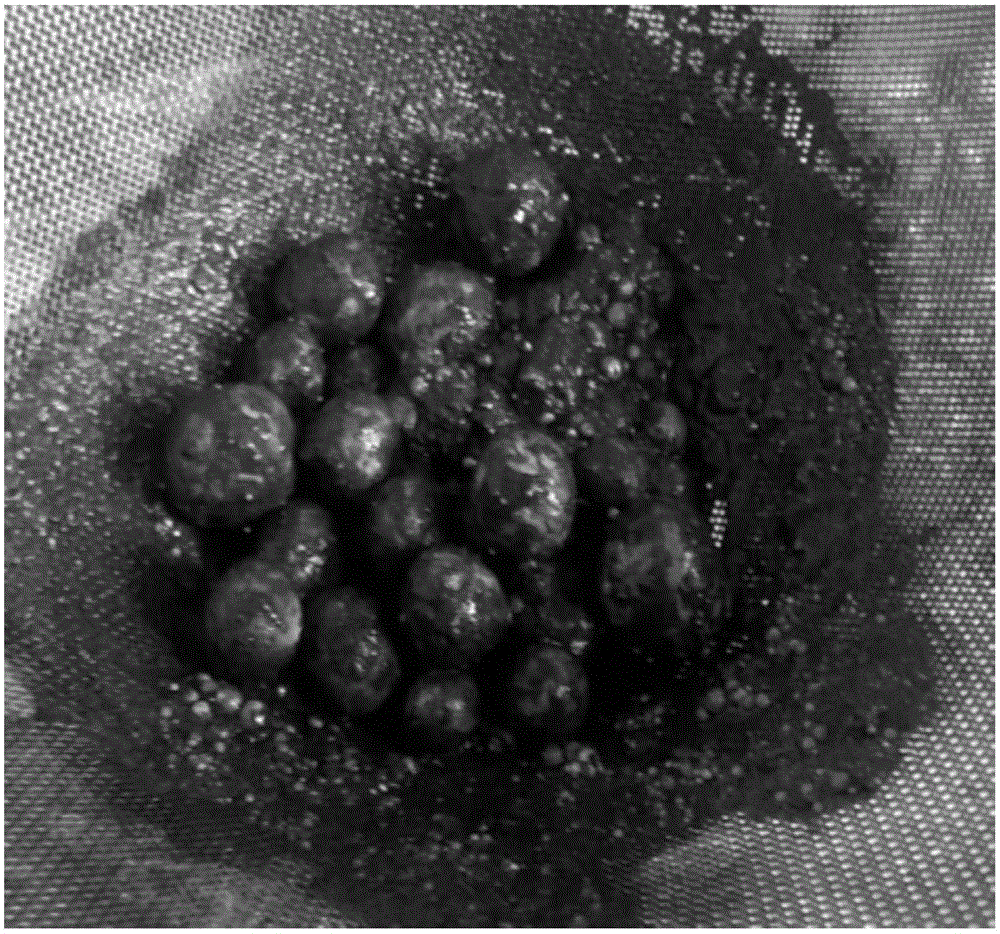

[0041] Obtain 103g metallic sodium on the 2.0mm metal strainer (such as Figure 4 Shown), metal sodium purity 99.5%. The filter residue was 39.0 g, and about 0.8 g of sodium metal remained in the filter residue.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com