Seabed natural gas hydrate slurry decomposition separation and mud sand removal modular mining system

A technology for hydrate slurry and natural gas, which is applied in the fields of fluid extraction, earthwork drilling, wellbore/well components, etc., which can solve the problems of abrupt pipe burst, high energy consumption, and easy occurrence of sand-blocking pipeline pressure, etc., to save energy, The effect of improving mining efficiency, improving mining efficiency and economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

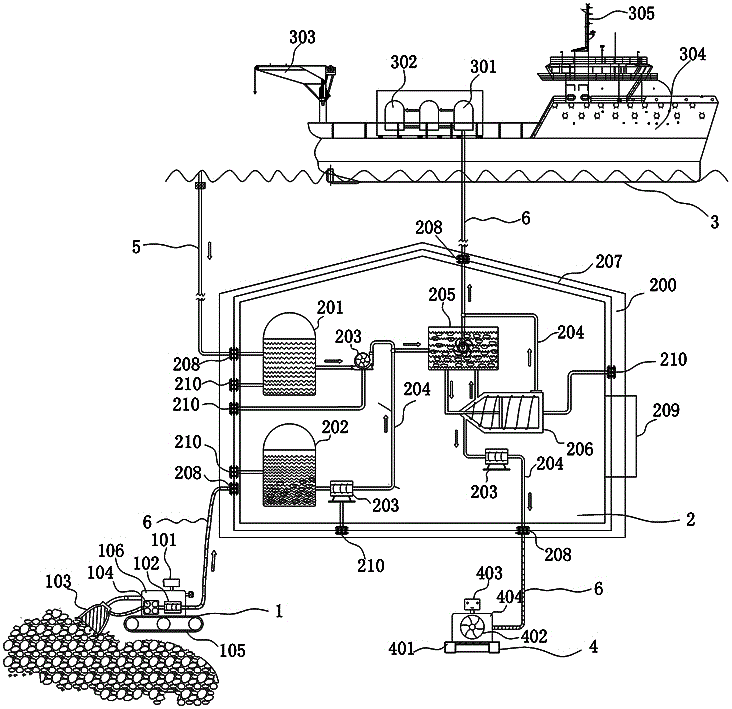

[0020] The system of the present invention regards the natural gas hydrate pool on the surface layer of the seabed as a seabed mineral resource, utilizes its characteristics of stable existence under seabed temperature and pressure, utilizes the internal rotary suction drill bit in the seabed mining robot 1 to break it, and adds an appropriate amount of seawater to crush the seabed The natural gas hydrate reservoir is turned into a slurry, and then transported to the subsea decomposition, separation and desedimentation collection and transportation treatment station 2, and after decomposition, separation and desedimentation treatment, the obtained natural gas hydrate slurry is transported to the offshore mining operation platform 3 , the separated sediment is backfilled in sit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com