Sensitive material for detecting methyl alcohol gas

A sensitive material and gas sensor technology, applied in the field of sensing, can solve the problem of low sensitivity, achieve high sensitivity and selectivity, and simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

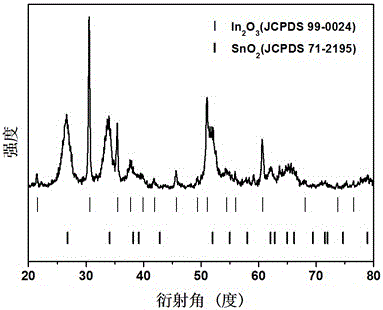

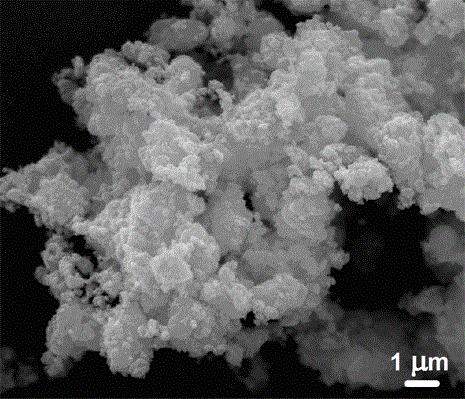

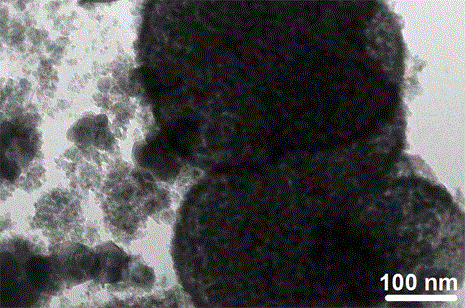

Image

Examples

Embodiment 1

[0023] (1) SnO 2 Preparation of Nanospheres

[0024] ① 4 mmol of tin chloride pentahydrate (SnCl 4 ·5H 2 O) Dissolve in 40mL of N,N - in a mixed solution of dimethylformamide (DMF) and deionized water, where N,N -The volume ratio of dimethylformamide (DMF) and deionized water is 1:2, then add 20mL (2mol / L) sodium hydroxide (NaOH) solution dropwise to it, and stir magnetically at room temperature to mix the solution evenly;

[0025] ②Transfer the above solution into a 90mL high-pressure hydrothermal kettle lined with polytetrafluoroethylene, seal it; keep it warm at 180°C for 24 hours, cool to room temperature, and wash the resulting precipitate with deionized water and absolute ethanol several times Centrifugal cleaning, and then drying in a constant temperature drying oven at 80 ° C for 24 hours to obtain SnO 2 nanospheres.

[0026] (2) Preparation of a sensitive material for detecting methanol gas

[0027] The SnO prepared in step (1) 2 nanospheres, and SiO 2 , PdCl...

Embodiment 2

[0032] (1) SnO 2 Preparation of Nanospheres

[0033] ① 4 mmol of tin chloride pentahydrate (SnCl 4 ·5H 2 O) Dissolve in 40mL of N,N - in a mixed solution of dimethylformamide (DMF) and deionized water, where N,N -The volume ratio of dimethylformamide (DMF) and deionized water is 1:2, then add 20mL (2mol / L) sodium hydroxide (NaOH) solution dropwise to it, and stir magnetically at room temperature to mix the solution evenly;

[0034] ②Transfer the above solution into a 90mL high-pressure hydrothermal kettle lined with polytetrafluoroethylene, seal it; keep it warm at 180°C for 24 hours, cool to room temperature, and wash the resulting precipitate with deionized water and absolute ethanol several times Centrifugal cleaning, and then drying in a constant temperature drying oven at 80 ° C for 24 hours to obtain SnO 2 nanospheres.

[0035] (2) Preparation of a sensitive material for detecting methanol gas

[0036] The SnO prepared in step (1) 2 nanospheres, and SiO 2 , Pd...

Embodiment 3

[0041] (1) SnO 2 Preparation of Nanospheres

[0042] ① 4 mmol of tin chloride pentahydrate (SnCl 4 ·5H 2 O) Dissolve in 40mL of N,N - in a mixed solution of dimethylformamide (DMF) and deionized water, where N,N -The volume ratio of dimethylformamide (DMF) and deionized water is 1:2, then add 20mL (2mol / L) sodium hydroxide (NaOH) solution dropwise to it, and stir magnetically at room temperature to mix the solution evenly;

[0043] ②Transfer the above solution into a 90mL high-pressure hydrothermal kettle lined with polytetrafluoroethylene, seal it; keep it warm at 180°C for 24 hours, cool to room temperature, and wash the resulting precipitate with deionized water and absolute ethanol several times Centrifugal cleaning, and then drying in a constant temperature drying oven at 80 ° C for 24 hours to obtain SnO 2 nanospheres.

[0044] (2) Preparation of a sensitive material for detecting methanol gas

[0045] The SnO prepared in step (1) 2 nanospheres, and SiO 2 , Pd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com