Variable-focus micro lens array structure based on electric actuation and preparation process thereof

A microlens array and actuation technology, which is applied in the field of zoom microlens arrays, can solve the problems of complex manufacturing process, phase difference, and difficulty in integration, and achieve the effects of superior performance, flexible focal length adjustment, and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings.

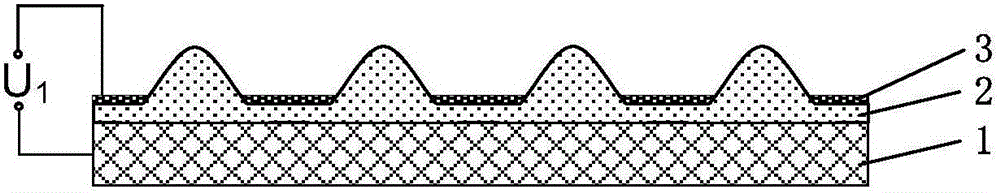

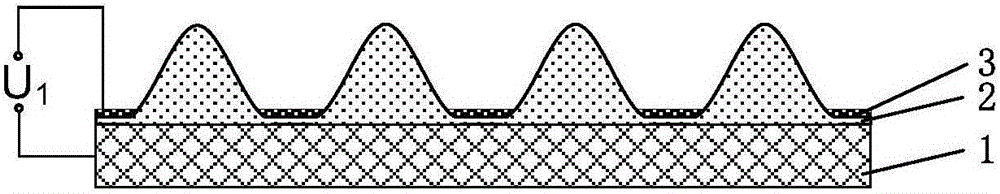

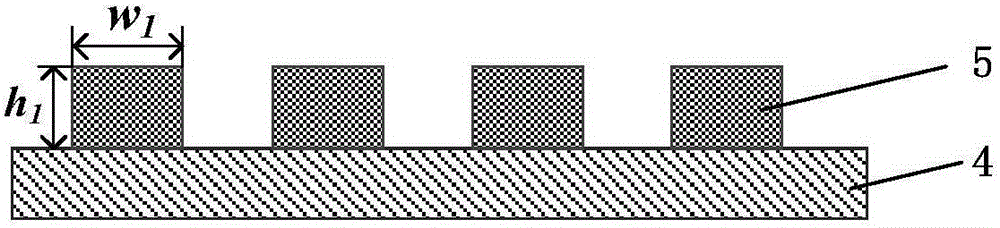

[0025] A zoom microlens array structure based on electric actuation, which is a "sandwich" structure, the bottom layer is a transparent conductive electrode 1, the middle layer is an elastic organic transparent polymer layer 2, and the top layer is a flexible conductive layer 3; no electric field U 1 , the flexible conductive layer 3 and the elastic organic transparent polymer layer 2 are in a stable initial state, such as figure 1 Shown; applied electric field U 1 At this time, the flexible organic transparent polymer layer 2 will be squeezed due to electrostatic attraction between the flexible conductive layer 3 and the transparent conductive electrode 1, resulting in a reduction in the thickness of the film, thereby generating an extrusion driving force on the raised area structure of the microlens array structure, lead to an increase in the curvature of the micr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com