Growth method of silicon carbide epitaxial layer with high surface quality

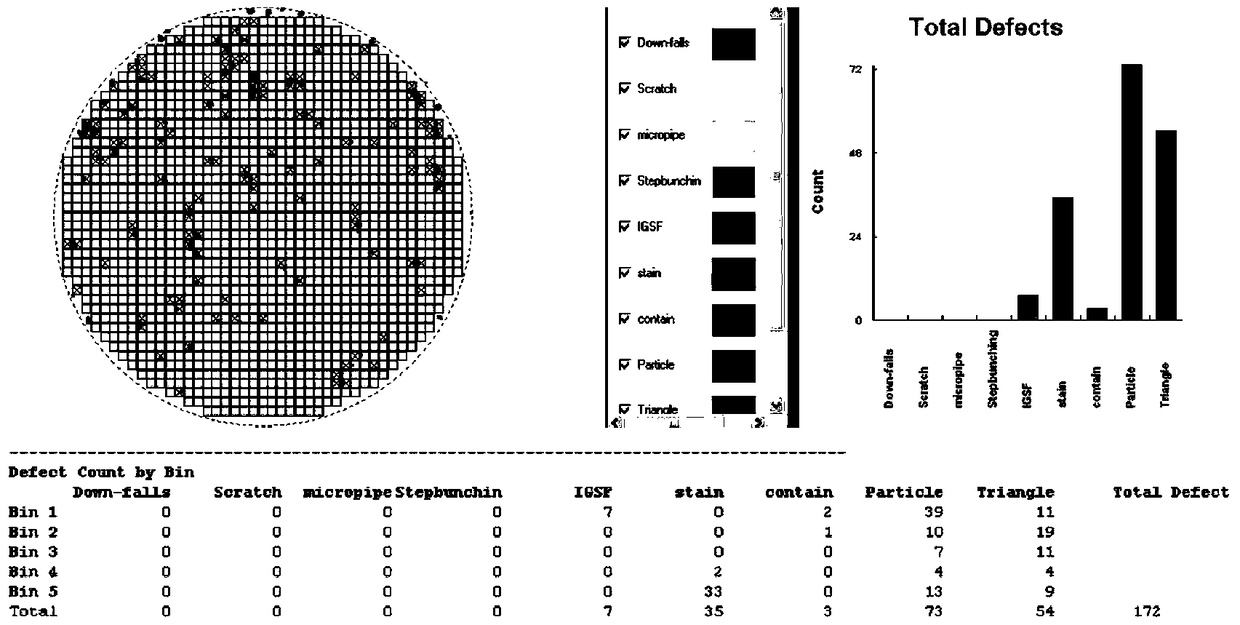

A technology of high-quality silicon carbide and growth methods, which is applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as device leakage and failure, and achieve the effect of reducing triangular defects and avoiding the formation of step bunching morphology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

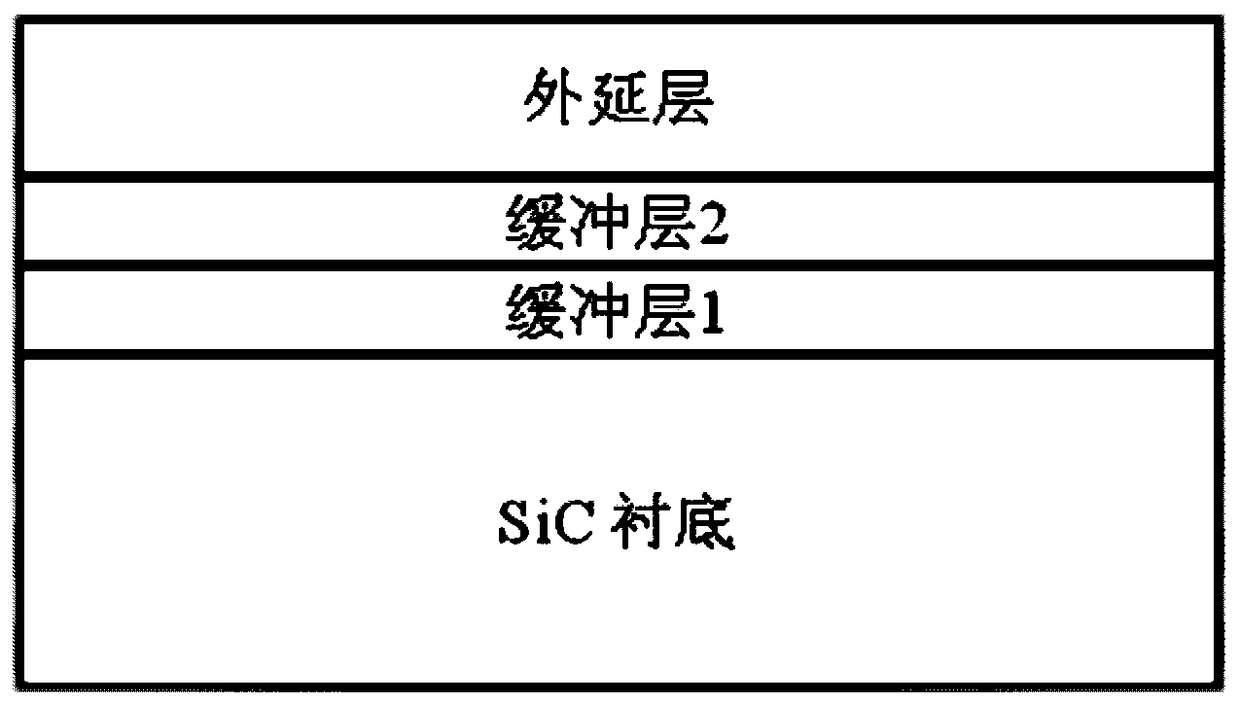

[0025] A method for growing a high-surface-quality silicon carbide epitaxial layer provided in a SiC chemical vapor deposition epitaxial system includes the following steps:

[0026] 1) Select a silicon carbide substrate with a silicon surface that is 4° to the direction, and place the substrate on a graphite base with a tantalum carbide coating in the reaction chamber of the SiC epitaxy system;

[0027] 2) The temperature of the system is raised to 1450°C, and the set pressure is 100mbar, under hydrogen (H 2 ) flow rate of 80L / min, maintain the temperature of the reaction chamber for 5 minutes, and carry out pure hydrogen (H 2 ) etching;

[0028] 3) Introduce a small amount of hydrogen chloride (HCl) into the reaction chamber to assist substrate etching, HCl / H 2 The flow ratio is set to 0.01%;

[0029] 4) Continue to raise the temperature, maintain the temperature for 5 minutes after reaching 1660°C, keep the flow rate of hydrogen chloride (HCl) constant, and continue to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com