Containment filtered venting system used for nuclear power plant

A discharge system, nuclear power plant technology, applied in the field of filter discharge system, can solve the problems of forming phenomenon, difficulty in production and installation, and decrease of removal efficiency of the same substance, so as to improve efficiency, reduce the possibility of physical failure, excellent radioactive aerosol/gas The effect of removing the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

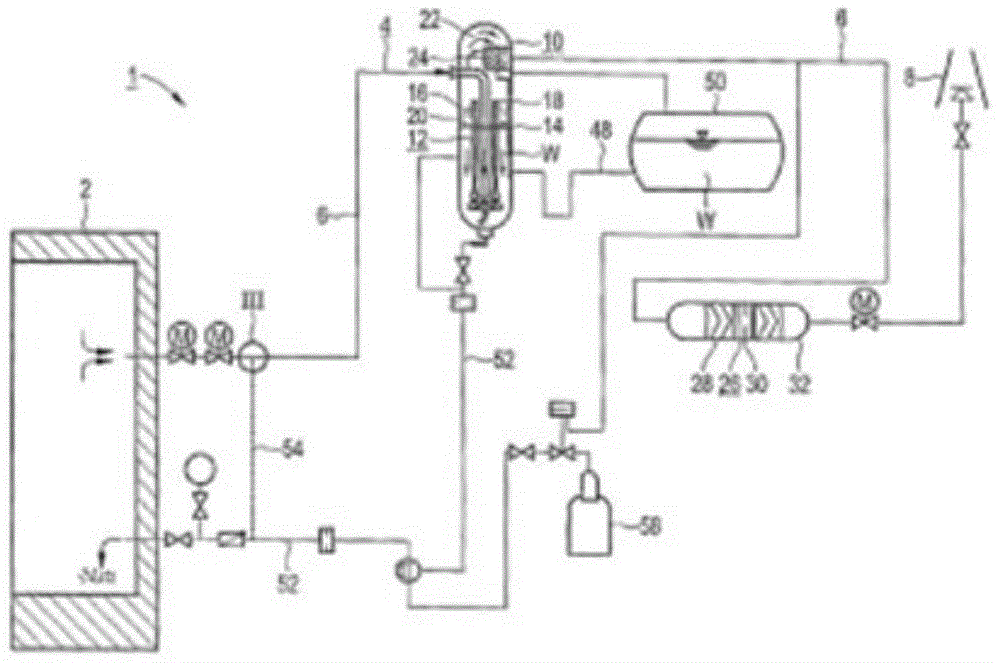

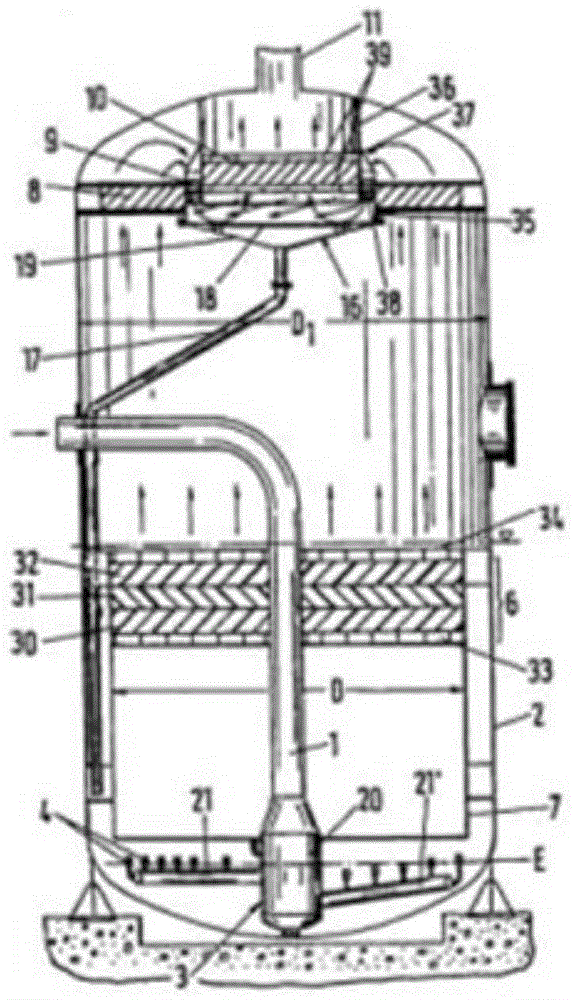

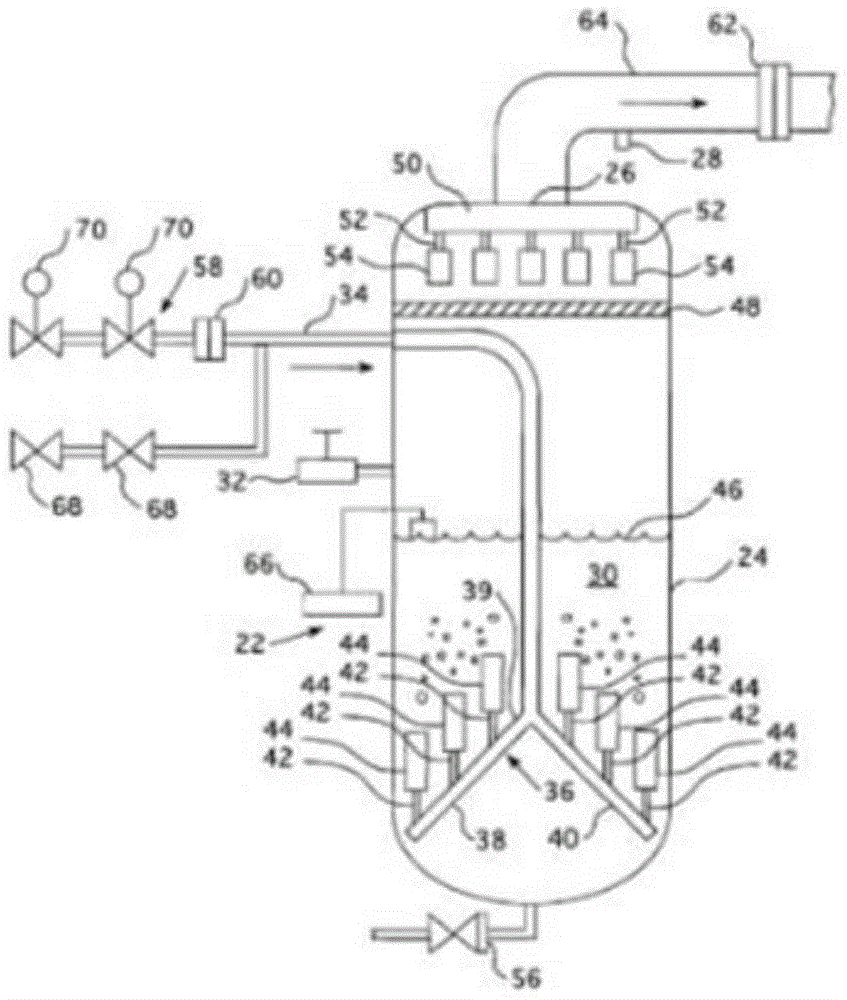

[0025] Hereinafter, the present invention will be described in detail with reference to the drawings. Figure 4 to Figure 8 It is a diagram showing an embodiment of the present invention. Figure 4 To illustrate the basic schematic diagram of the present invention, the product of the present invention includes an inlet pipe connected to a nuclear reactor building, a filter discharge container, a throttle orifice, a molecular sieve and an outlet pipe, and more than two isolation pipes are formed in the inlet pipe. valve.

[0026] In addition, the filter discharge container is composed of a metal fiber filter including a combined nozzle (CombinedNozzle), a cyclone separator, and a pretreatment filter, and the external throttling orifice and molecular sieve can be located inside the filter discharge container, including pretreatment filter The metal fiber filter and molecular sieve of the device can all be located outside, and an outlet isolation valve can be formed in the outle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com