Capsicum seed coating agent and preparation method thereof

A technology of coating agent and seeds, which is applied in the field of capsicum seed coating agent and its preparation, can solve the problems of single efficacy and capsicum coating agent can not improve the stress resistance and disease resistance of seeds at the same time, and achieve the overcoming effect Single, improve disease resistance, accelerate the effect of germination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

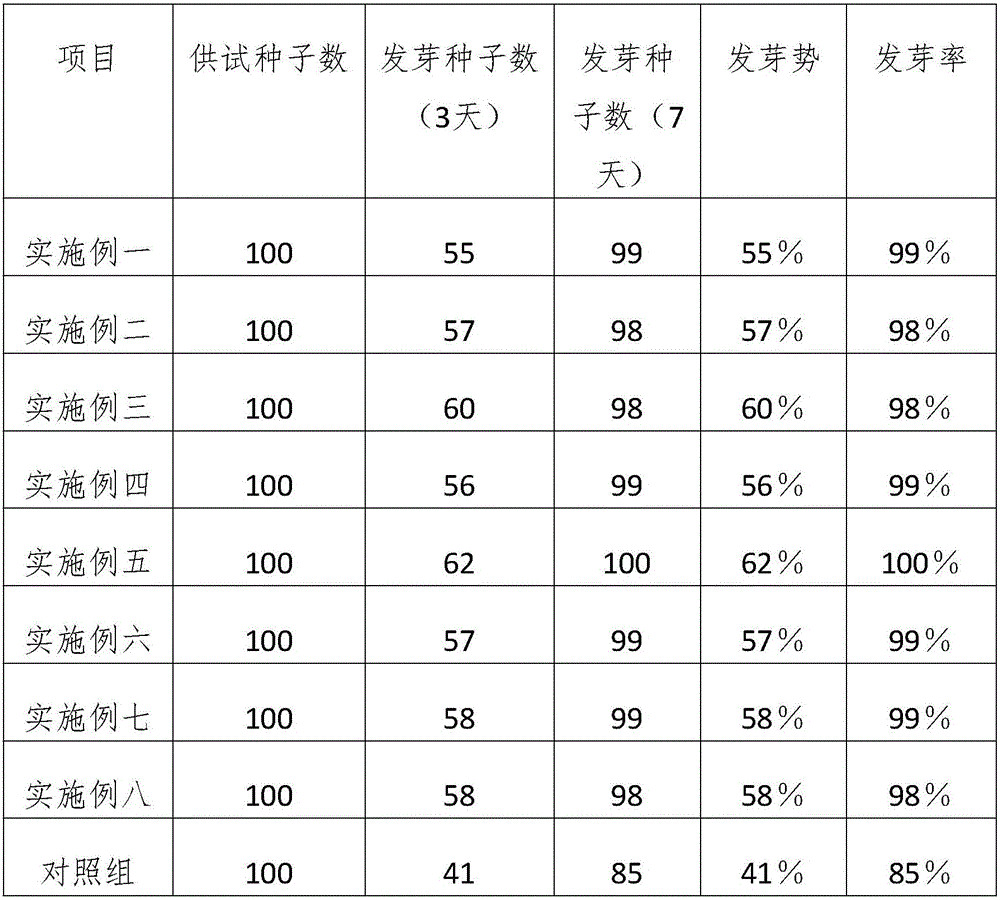

Examples

Embodiment 1

[0021] Formula 1: 15 parts of fungicide, 5 parts of insecticide, 4 parts of agar, 3 parts of sodium alginate, and 1 part of auxiliary material.

[0022] Formula 2: 20 parts of fungicide, 10 parts of insecticide, 5 parts of agar, 4 parts of sodium alginate, and 2 parts of auxiliary materials.

[0023] Formula 3: 25 parts of fungicide, 15 parts of insecticide, 6 parts of agar, 5 parts of sodium alginate, and 3 parts of auxiliary materials.

[0024] Preparation:

[0025] a. Preparation: Dissolve agar and sodium alginate in water first, then heat to 90°C, and then add 5% metalaxyl seed coating agent and 10% imidacloprid to prepare a gel-like viscous liquid;

[0026] b. Finished product: add potassium dihydrogen phosphate, boric acid, magnesium sulfate, manganese sulfate, and zinc sulfate to the prepared colloidal viscous liquid according to the mass ratio of 5:1.5:1.25:1:1. Auxiliary materials, mix evenly and cool to 40°C to obtain capsicum seed coating agent. When using, stir t...

Embodiment 2

[0028] Formula 1: 15 parts of fungicide, 5 parts of insecticide, 4 parts of agar, 3 parts of sodium alginate, and 1 part of auxiliary material.

[0029] Formula 2: 20 parts of fungicide, 10 parts of insecticide, 5 parts of agar, 4 parts of sodium alginate, and 2 parts of auxiliary materials.

[0030] Formula 3: 25 parts of fungicide, 15 parts of insecticide, 6 parts of agar, 5 parts of sodium alginate, and 3 parts of auxiliary materials.

[0031] Preparation:

[0032] a. Preparation: Dissolve agar and sodium alginate in water first, then heat to 90°C, then add 10% metalaxyl seed coating agent and 10% imidacloprid to prepare a colloidal viscous liquid;

[0033] b. Finished product: add potassium dihydrogen phosphate, boric acid, magnesium sulfate, manganese sulfate, and zinc sulfate to the prepared colloidal viscous liquid according to the mass ratio of 5:1.5:1.25:1:1. Auxiliary materials, mix evenly and cool to 40°C to obtain capsicum seed coating agent. When using, stir the...

Embodiment 3

[0035] Formula 1: 15 parts of fungicide, 5 parts of insecticide, 4 parts of agar, 3 parts of sodium alginate, and 1 part of auxiliary material.

[0036] Formula 2: 20 parts of fungicide, 10 parts of insecticide, 5 parts of agar, 4 parts of sodium alginate, and 2 parts of auxiliary materials.

[0037] Formula 3: 25 parts of fungicide, 15 parts of insecticide, 6 parts of agar, 5 parts of sodium alginate, and 3 parts of auxiliary materials.

[0038] Preparation:

[0039] a. Preparation: Dissolve agar and sodium alginate in water first, then heat to 90°C, then add 15% metalaxyl seed coating agent and 10% imidacloprid to prepare a viscous liquid;

[0040] b. Finished product: add potassium dihydrogen phosphate, boric acid, magnesium sulfate, manganese sulfate, and zinc sulfate to the prepared colloidal viscous liquid according to the mass ratio of 5:1.5:1.25:1:1. Auxiliary materials, mix evenly and cool to 40°C to obtain capsicum seed coating agent. When using, stir the coating a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com