Automatic device for preventing necking during welding

An automatic necking technology, applied in the direction of auxiliary devices, welding equipment, welding equipment, etc., can solve the problems of low welding efficiency, inability to improve the welding quality of welding parts, and irreparable problems, so as to improve welding efficiency, improve welding quality, Solve the effect of welding deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

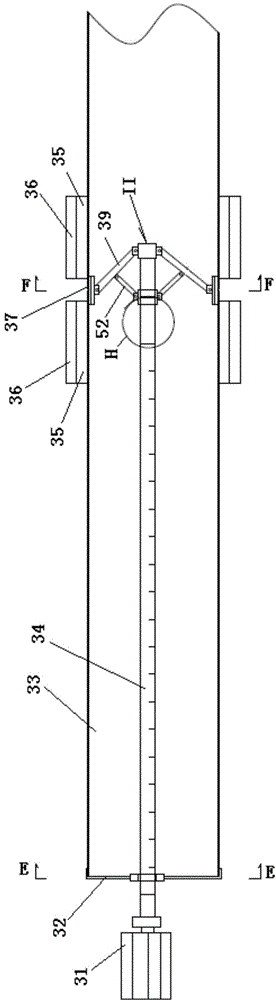

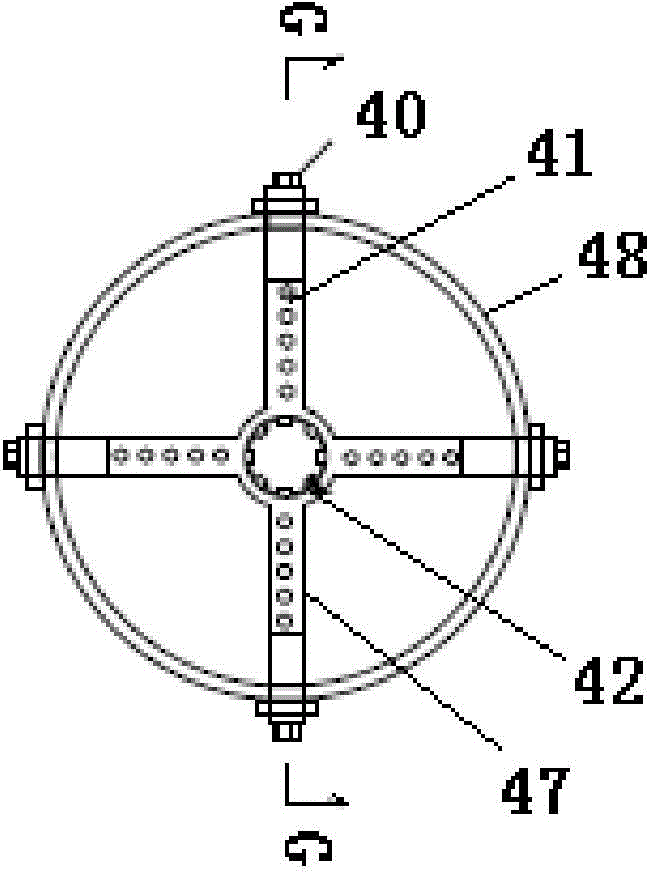

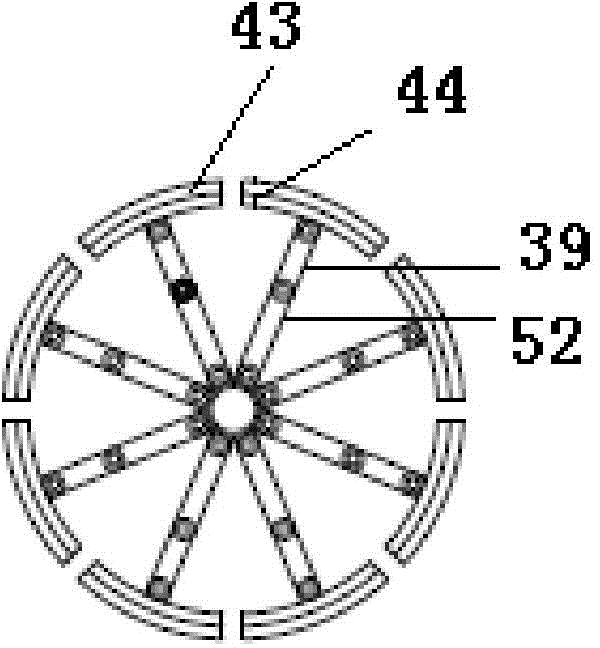

[0036] like figure 1 shown, see also Figure 2 to Figure 5 , this example uses figure 1 For the purpose of explanation, the present invention provides an automatic welding necking prevention device, which is installed on the pipeline 33. The automatic welding necking prevention device includes: a heating mechanism 35, a welding protective layer 36 and a support mechanism II ,

[0037] The heating mechanism 35 is used to provide thermal energy to the pipe 33 and to provide preheating and heat preservation for the welded part of the pipe 33,

[0038] The welding protection layer 36 is arranged on the welding part of the pipeline 33, and the welding protection layer 36 is used for heat preservation of the welding part of the pipeline 33,

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com