Acid-sensitive amphipathic stearic acid amidated glucan polymer nano-micelle and preparation method thereof

A technology of stearic acid amidated glucan and fatty acid amidated glucan is applied in the field of drug-loaded micelles and their preparation, which can solve the problems of no pH response of stearic acid glucan micelles and the like, and achieve drug-loaded micelles. Release the effect of enhancing and enhancing solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

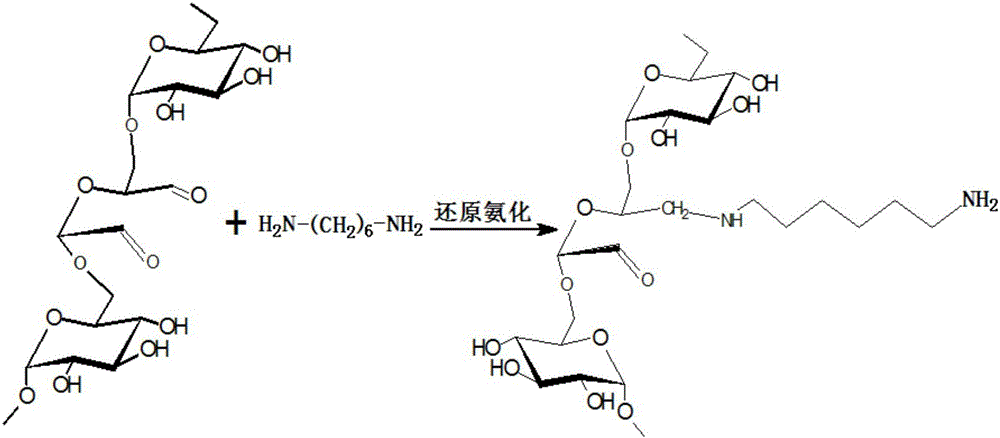

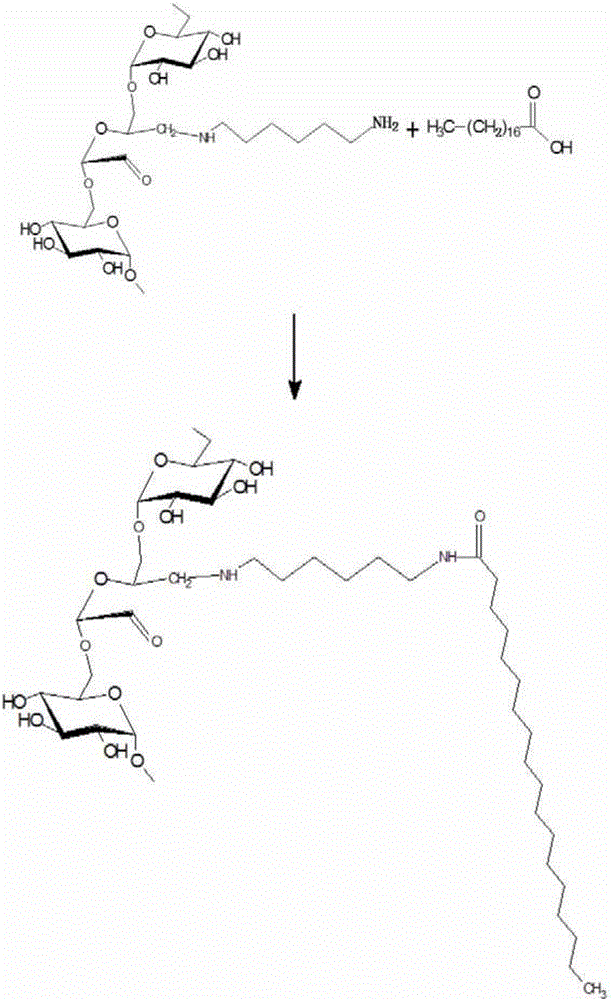

[0036] Specific embodiment 1: This embodiment is an acid-sensitive amphiphilic stearic acid amidated dextran polymer nanomicelle, which uses dextran as a raw material and introduces reactive aldehydes on the surface of the dextran structure through an oxidation reaction Base to obtain polyaldehyde dextran, and then react polyaldehyde dextran with hexamethylene diamine to generate hexamethylene diamine-polyaldehyde dextran. The hexamethylene diamine-polyaldehyde dextran has a stable carbon Bond structure and carrying active amino groups; hexamethylenediamine-polyaldehyde dextran is acylated with stearic acid to obtain stearic acid amidated dextran polymer, and the amphiphile of stearic acid amidated dextran polymer It self-assembles into nanomicelles in water, which is acid-sensitive amphiphilic stearic acid amidated dextran polymer nanomicelles.

specific Embodiment approach 2

[0037] Specific embodiment 2: This embodiment is a method for preparing acid-sensitive amphiphilic stearic acid amidated dextran polymer nanomicelles, which is specifically completed as follows:

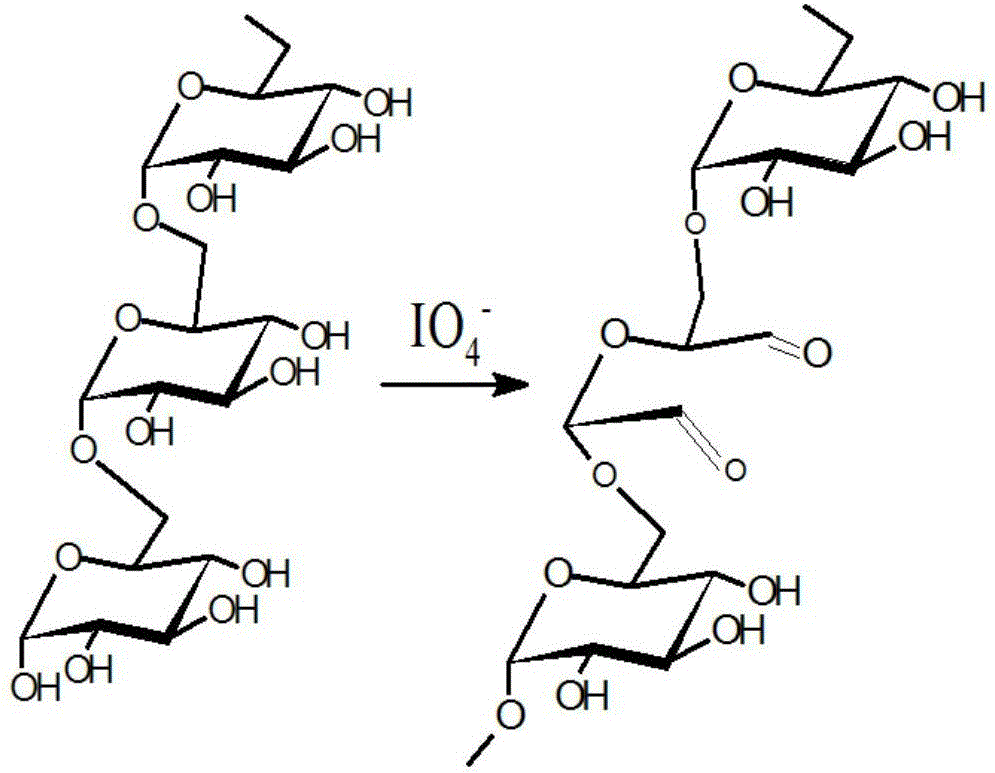

[0038] 1. Preparation of polyaldehyde dextran: ①. Dissolve dextran in distilled water to obtain an aqueous solution of dextran with a concentration of 5mmol / L~15mmol / L; ②. Dissolve sodium periodate in distilled water to obtain concentration Sodium periodate aqueous solution of 0.11mol / L~0.33mol / L; ③, the concentration of dextran aqueous solution with the concentration of 5mmol / L~15mmol / L and the concentration of 0.11mol / L~0.33mol / under dark conditions L sodium periodate aqueous solution was mixed, and the reaction was stirred for 4h-8h at a temperature of 25°C and a rotation speed of 800r / min~1600r / min in a dark condition to obtain the reaction product. The reaction product was transferred to the dialysis bag. The molecular weight cut-off of the dialysis bag is 3500, the deionized wate...

specific Embodiment approach 3

[0046] Specific embodiment three: The difference between this embodiment and the specific embodiment two is: the average molecular weight of the glucan in step one (1) is 10,000. Others are the same as the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com