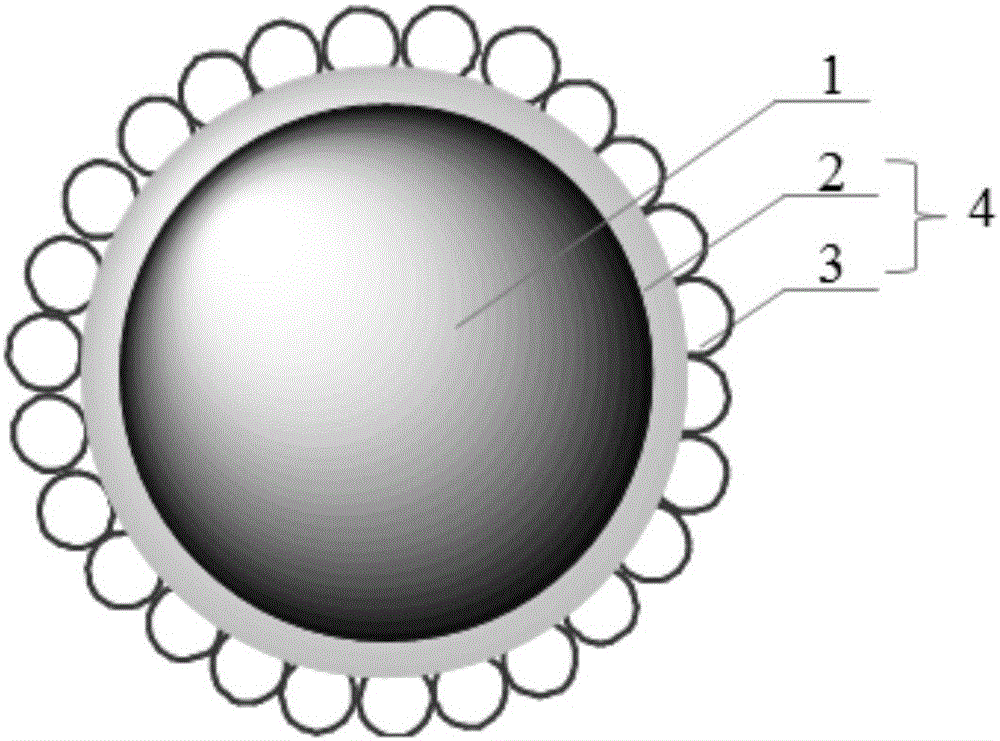

Slow-release essence microcapsule and preparation method thereof

A flavor microcapsule and slow-release technology, which is applied in the field of daily chemical industry, can solve the problems of sensitivity, fragrance retention period cannot be guaranteed, flavor is easy to volatilize, etc., and achieve the effect of increasing solubility, slowing down the loss of rapid volatilization, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

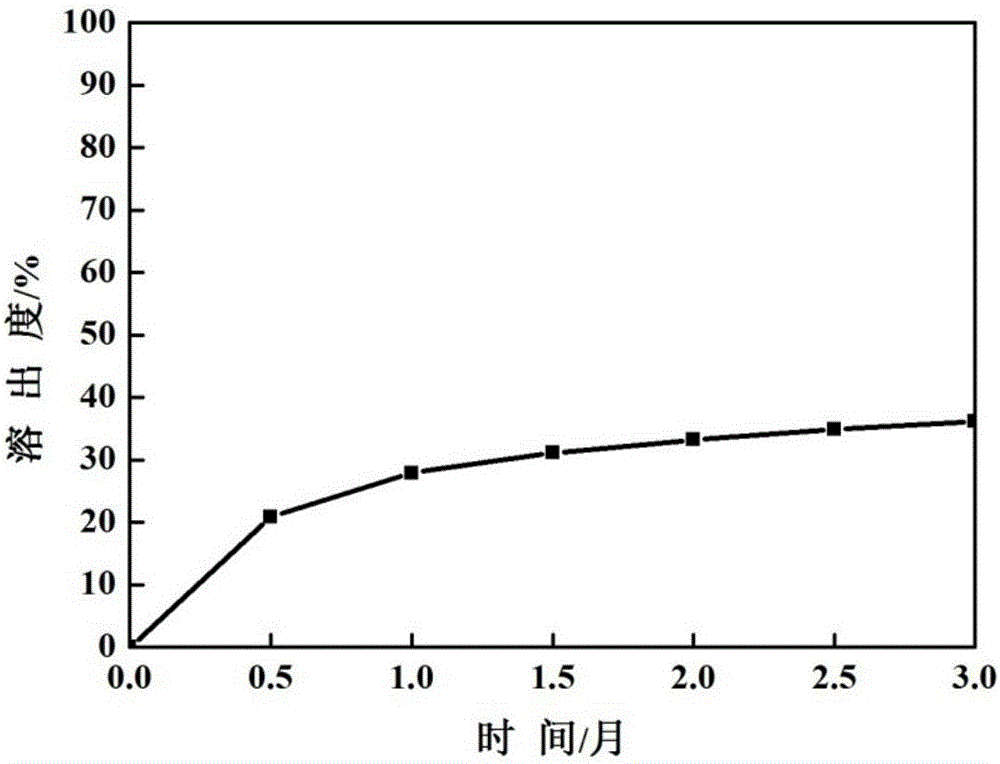

Examples

Embodiment 1

[0029] (1) Preparation of β-cyclodextrin / paraffin inclusion compound suspension

[0030] Accurately weigh 4.5g of β-cyclodextrin and 0.5g of paraffin into a round-bottomed flask, slowly add 90g of deionized water, stir at 40°C at 600rpm for 0.5h to completely clathrate β-cyclodextrin and paraffin, and cool Obtain β-cyclodextrin / paraffin inclusion compound suspension.

[0031] (2) Preparation of mixed oil phase

[0032] Accurately weigh 9 g of n-octadecane, 3 g of orange oil essence, 10 g of methyl methacrylate, and 0.11 g of azobisisobutyrocyanide in a round bottom flask, and stir at 35° C. at 250 rpm for 0.5 h to obtain a mixed oil phase.

[0033] (3) Preparation of Pickering emulsion

[0034] Add the suspension in step (1) completely dropwise to the mixed oil phase in step (2), and stir at 40°C at 800rpm for 1 hour, so that the mixed oil phase can react under the action of β-cyclodextrin / paraffin clathrate The Pickering emulsion is obtained by uniformly dispersing in wate...

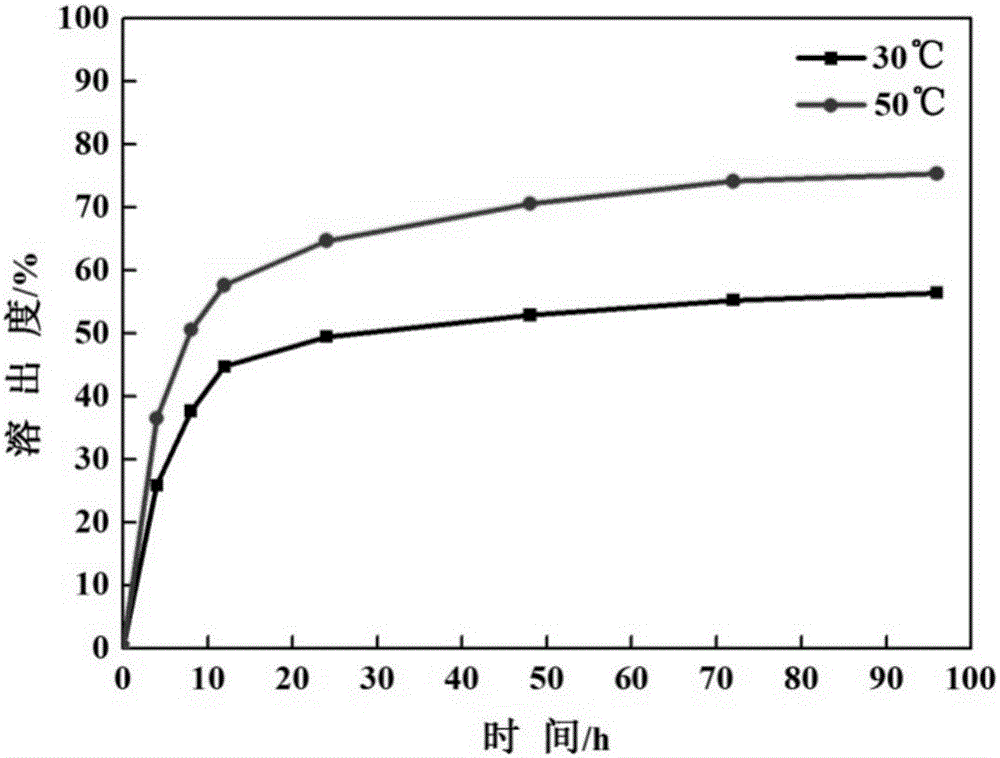

Embodiment 2

[0040] (1) Preparation of γ-cyclodextrin / beeswax clathrate suspension

[0041]Accurately weigh 4g of γ-cyclodextrin and 0.8g of beeswax into a round-bottom flask, slowly add 60g of deionized water, stir at 80°C and 800rpm for 1 hour, make the inclusion of γ-cyclodextrin and beeswax complete, and cool to obtain γ-cyclodextrin - Cyclodextrin / beeswax clathrate suspension.

[0042] (2) Preparation of mixed oil phase

[0043] Accurately weigh 10g of white oil, 1g of lily essence, 18g of butyl methacrylate, 2g of trimethylolpropane triacrylate, and 0.2g of benzoyl peroxide in a round bottom flask, and stir at 20°C at 600rpm for 0.25h, A mixed oily phase was obtained.

[0044] (3) Preparation of Pickering emulsion

[0045] Add the suspension in step (1) dropwise to the mixed oil phase in step (2), stir at 20°C at 1000rpm for 0.5h, make the mixed oil phase in the γ-cyclodextrin / beeswax clathrate Under the action, it is uniformly dispersed in water in the form of small droplets to ...

Embodiment 3

[0051] (1) Preparation of α-cyclodextrin / palm wax clathrate suspension

[0052] Accurately weigh 4.8g of α-cyclodextrin and 0.8g of palm wax into a round bottom flask, slowly add 85g of deionized water, and stir at 900rpm at 65°C for 1.25h to completely clathrate α-cyclodextrin and palm wax. Cool to obtain α-cyclodextrin / palm wax clathrate suspension.

[0053] (2) Preparation of mixed oil phase

[0054] Accurately weigh 20g of sunflower oil, 4g of rose essence, 6g of methyl acrylate, 4g of lauryl methacrylate, and 0.1g of benzoyl peroxide in a round bottom flask, and stir at 50°C at 400rpm for 0.16h to obtain a mixed oil Mutually.

[0055] (3) Preparation of Pickering emulsion

[0056] Add the suspension in step (1) dropwise to the mixed oil phase in step (2), stir at 50°C at 700rpm for 0.75h, and make the mixed oil phase in the α-cyclodextrin / palm wax clathrate Under the action of the action, it is uniformly dispersed in water in the form of small droplets to obtain a Pic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com