A method for producing pure steel by one-step direct reduction of coal-to-gas

A pure steel and coal-to-gas technology, applied in the field of smelting reduction ironmaking, can solve the problems of poor scale efficiency, low efficiency, and short service life of tank materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

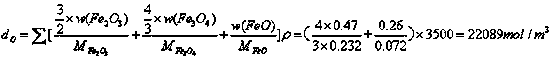

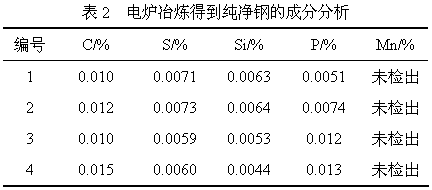

[0104] Example 1: Annual production of 100,000 tons of pure steel using iron oxide pellets.

[0105] Raw materials: 1) 73,000 tons of long-flame coal, including 6% ash, 33% volatile matter, 60% fixed carbon, 0.28% sulfur, and a particle size of 40-60mm; 2) 160,000 tons of iron oxide pellets, whose composition See the table below.

[0106]

[0107] Heat long-flame coal at a heating rate of 70°C / min to 650°C for pyrolysis, process 9 tons per hour, and accumulatively obtain 5,800 tons of light tar and 29.2 million Nm of 73,000 tons of long-flame coal 3 Pyrolysis gas, 43,000 tons of spongy fixed carbon. Light tar of which is sold as a commercial product.

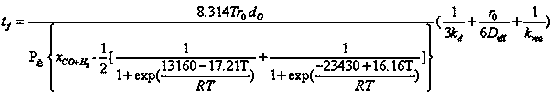

[0108] 60% of the total pyrolysis gas (17.52 million Nm 3 ) as an energy source, heat 68% (29,240 tons) of spongy fixed carbon obtained by pyrolysis to 850-1100°C at a rate of 3.65 tons per hour, and pass 5.18×10 water vapor with a pressure of 0.1MPa and a temperature of 450K 7 N m 3 , the reaction system obtained reduci...

Embodiment 2

[0117] Example 2: 100,000 tons of pure steel is produced annually by using Indonesian sea sand ilmenite.

[0118] Raw materials: 1) 78,000 tons of non-caking coal, including 6% ash, 35% volatile, 62% fixed carbon, 0.26% sulfur, particle size 40~60mm; 2) pellets made of Indonesian sea sand ilmenite The ore is 18,500 tons, and its composition is as follows.

[0119]

[0120] Heat the non-caking coal at a heating rate of 75℃ / min to 680℃ for pyrolysis, process 9 tons per hour, and accumulatively obtain 6197 tons of light tar and 31.2 million Nm of 78,000 tons of non-caking coal 3 Pyrolysis gas and 45,900 tons of spongy fixed carbon.

[0121] 60% of the total pyrolysis gas (1.87 million Nm 3 ) as an energy source, heat 65% (31,200 tons) of the spongy fixed carbon obtained by pyrolysis to 850-1100°C at a rate of 3.9 tons per hour, and feed 5.53×10 water vapor with a pressure of 0.1MPa and a temperature of 450K 7 N m 3 , the reaction system obtains reducing gas, where (CO+H 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com