Method for recovering valuable metals from high-silicon low-germanium and low-indium zinc oxide soot

A valuable metal, zinc oxide technology, applied in the field of hydrometallurgy, can solve the problems of serious organic phase emulsification, high suspended solids, high silicon content, and achieve the effects of low water content, recycling, and comprehensive recycling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

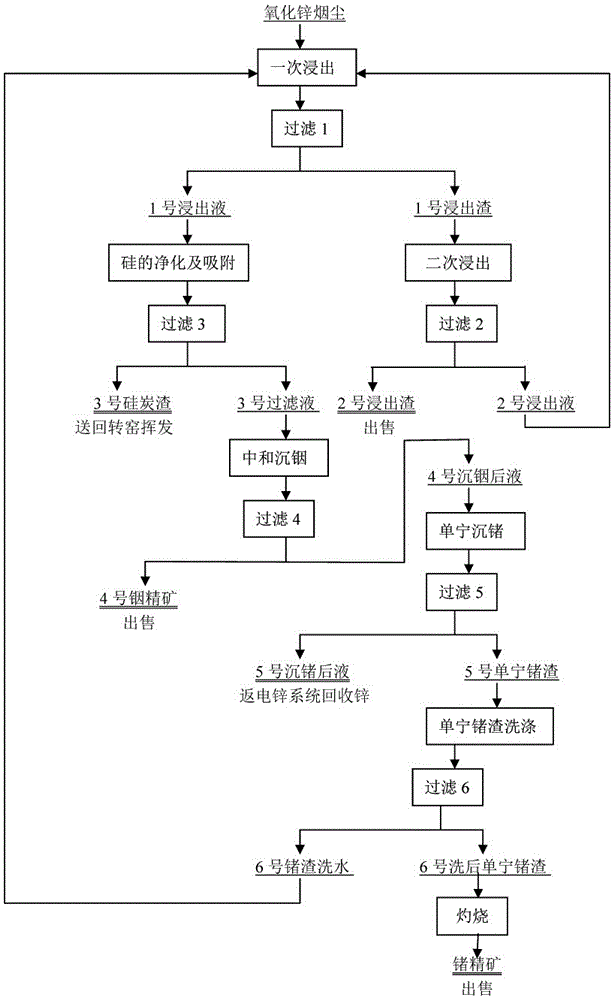

Image

Examples

Embodiment 1

[0039] Zinc oxide fumes produced by volatilization of rotary kiln leaching slag from wet smelting zinc electricity Co., Ltd. in Yunnan Luoping Zinc Electric Co., Ltd. were dried and shrunk to 20,000.00 grams for sample preparation. The ingredients were: zinc 50.18wt%, germanium 0.0208wt %, indium 0.0153wt%, lead 6.58wt%, silicon dioxide 5.43wt%, silver 0.0030wt%, iron 4.27wt%.

[0040] (1) Primary leaching: use industrial water as pre-liquid, take 72 liters, add zinc oxide fume to 12000.0 grams for slurrying, slurrying time is 20 minutes, adjust initial acidity to 120g / l with concentrated sulfuric acid, control process temperature 75°C , The leaching time is 1.0 hours, and the end point pH=1.1, then filter 1. Filtration 1 produces No. 1 leaching residue for secondary leaching and contains 107.67g / l zinc, 0.021g / l indium, 6.54 g / l silicon dioxide, 0.028g / l germanium, 0.0026 g / l lead, and 0.00019g / l silver 1. 48.50 liters of No. 1 leach solution of ferrous iron 7.14g / l and ferr...

Embodiment 2

[0052] Zinc oxide fumes produced by rotary kiln volatilization of leaching slag from wet smelting zinc electricity Co., Ltd. in Yunnan Luoping Zinc Electric Co., Ltd. After drying, 18,000.00 grams of samples were prepared by shrinking and dividing. The components are: zinc 55.08wt%, germanium 0.0306wt %, indium 0.0249wt%, silicon dioxide 8.08wt%, lead 9.96wt%, silver 0.0048wt%, iron 5.94wt%.

[0053] (1) Primary leaching: Use industrial water as the pre-liquid, take 70 liters, add zinc oxide fume to 10000.0 grams for slurrying, the slurrying time is 30 minutes, adjust the initial acid to 130g / l with concentrated sulfuric acid, and control the process temperature to 85°C , the leaching time is 1.5 hours, and the end point pH=1.5, then filter 1; the output No. 1 leaching slag is subjected to secondary leaching and contains 100.79g / l zinc, 0.0301g / l indium, 9.06 g / l silicon dioxide, and 0.0358g germanium 47.0 liters of No. 1 leach solution of / l, lead 0.0027g / l, silver 0.0002g / l,...

Embodiment 3

[0065] Zinc oxide fumes produced by rotary kiln volatilization of leaching slag from hydrometallurgy of Yunnan Luoping Zinc Electric Co., Ltd., containing 50wt% zinc, 0.02wt% germanium, 0.015wt% indium, 6wt% lead, and 5wt% silicon dioxide %, silver 0.003wt%, iron 4wt%.

[0066] 1) Primary leaching: Slurry zinc oxide dust with zinc electrolysis waste liquid at a liquid-solid ratio of 6:1 for 25 minutes, adjust initial acid 125g / l with concentrated sulfuric acid, control process temperature at 80°C, and leaching time After 1.2 hours and the end point pH=1.2, filter 1, filter 1 to produce No. 1 leaching residue and No. 1 leaching solution, No. 1 leaching residue for secondary leaching, and No. 1 leaching solution for silicon purification and adsorption;

[0067] 2) Secondary leaching: Slurry No. 1 leaching slag with industrial water at a liquid-solid ratio of 4:1, use concentrated sulfuric acid to adjust the initial acid to 135g / l, control the process temperature to 92°C, the lea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sedimentation rate | aaaaa | aaaaa |

| Sedimentation rate | aaaaa | aaaaa |

| Sedimentation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com