Metal guide plate capable of improving screw-setting precision in spinal operation and manufacturing method of metal guide plate

A manufacturing method and surgical technology, applied in the fields of surgery, medical science, computer-aided planning/modeling, etc., can solve the problem of large gap between template and metal drill, inability to customize personalized surgical tools and surgical implants, and large navigation deviation and other problems, to achieve the effect of shortening the learning curve and marking, reducing iatrogenic surgical complications, and accurately placing nails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

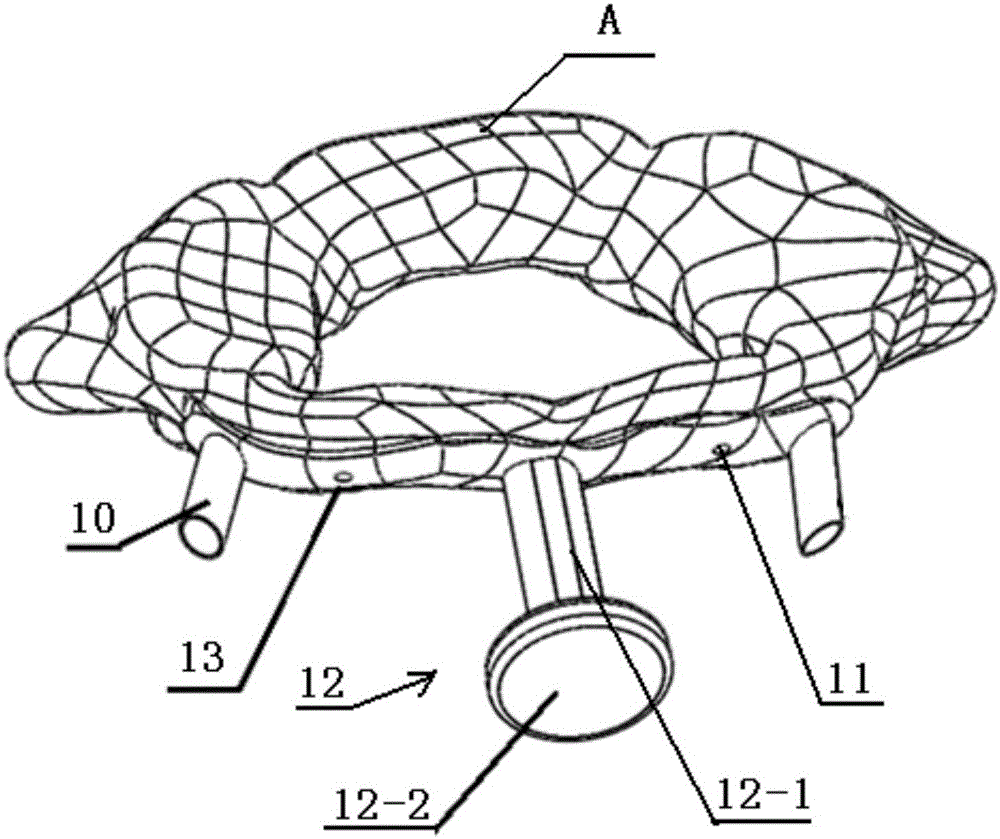

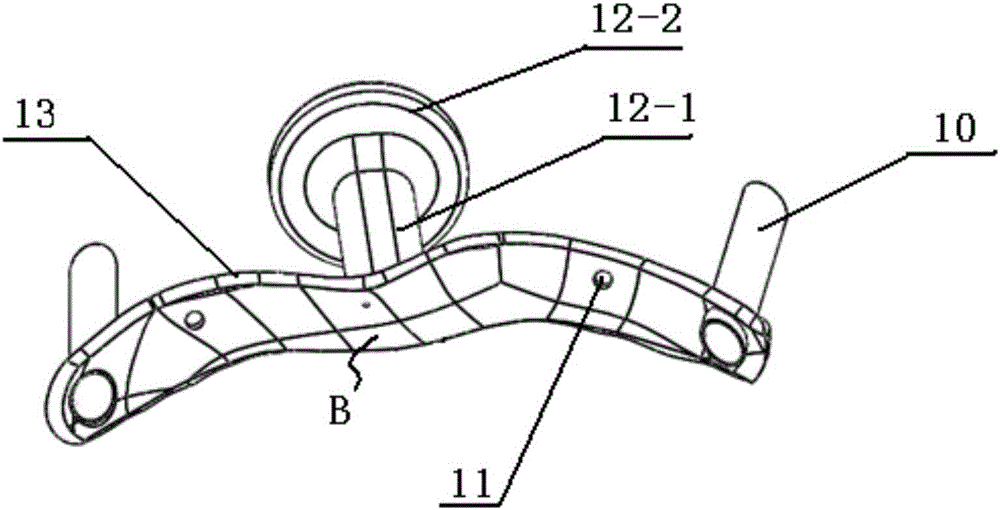

[0029] Such as Figures 1 to 3 shown. The present invention utilizes the combination of industrial design software and medical software to design a personalized surgical guide plate that fits the surface of the cervical spine according to the surgical plans of different patients. The operator uses the guide plate for positioning and nail placement, which reduces the risk during the operation, shortens the operation time, and reduces the injury to the patient during the operation.

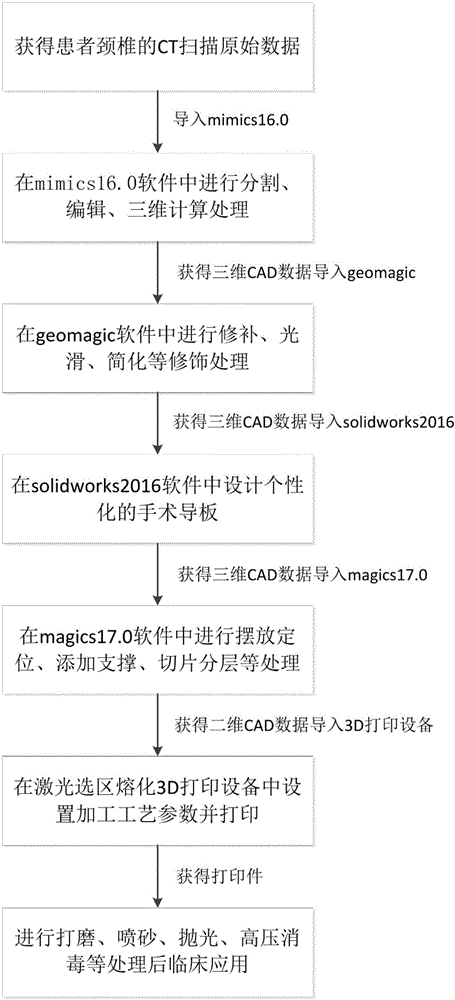

[0030] The invention utilizes the medical software mimics16.0 to transform the patient's CT scan data into three-dimensional information, extract the target cervical vertebra, and save it in STL format. Then use the medical software geomagic for further smoothing and denoising processing, and save as STEP AP203 format.

[0031] Import the saved STEP AP203 format file into the industrial design software solidworks2016, and draw the surgical guide plate. The specific steps are as follows: due to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com