A high-frequency sieve with automatic amplitude adjustment and automatic adjustment method

An automatic adjustment, high-frequency sieve technology, applied in chemical instruments and methods, filter sieves, solid separation, etc., can solve the problems of inability to automatically adjust the amplitude, the formation of stacking phenomenon, the failure to reach the amplitude, etc., and achieve process layout and realization. Easy, accurate vibration state, accurate and controllable amplitude

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

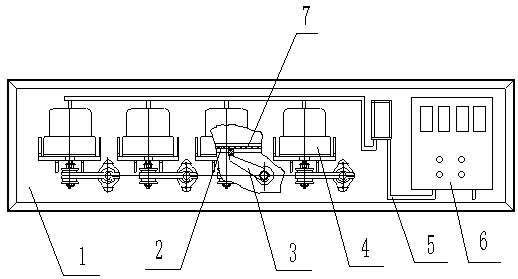

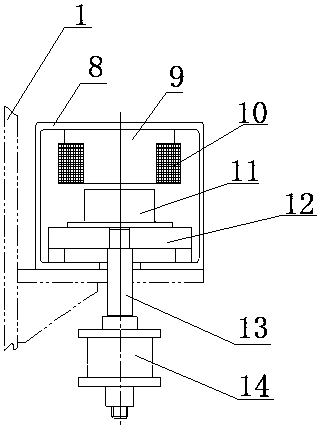

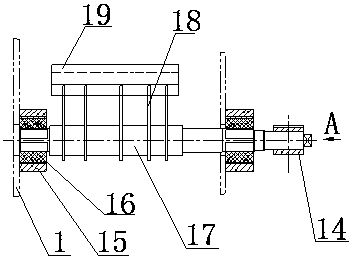

[0029]A high-frequency screen with automatic amplitude adjustment, including a screen frame 1, a screen mesh 2, a vibrating shaft 3, a vibrator 4, a wiring pipe 5 and a controller 6, the screen mesh 2 is installed on the screen frame 1 through a mesh spring 7, At the same time, it is overlapped with the vibration shaft 3; the vibration shaft 3 is installed on the screen frame 1, one end of the vibration shaft 3 is overlapped with the screen 2, and the other end is hinged with the vibrator 4; the vibrator 4 is installed on the screen frame 1, and the vibrator 4 The output end is hinged with the vibration shaft 3; the wiring tube 5 connects the signal line of the vibrator 4 and the controller 6; the controller 6 is installed on the screen frame 1; the screen 2, the screen spring 7, the vibration shaft 3 and the vibration The device 4 constitutes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com