Preparation method of sorbitan octoate

A technology of sorbitan and monocaprylate, applied in the field of preparation of daily chemical additives, can solve the problems of insufficient stability of the system, violent reaction, short time, etc., and achieves improved antiseptic and antibacterial effect, obvious synergistic effect, and a reaction process. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

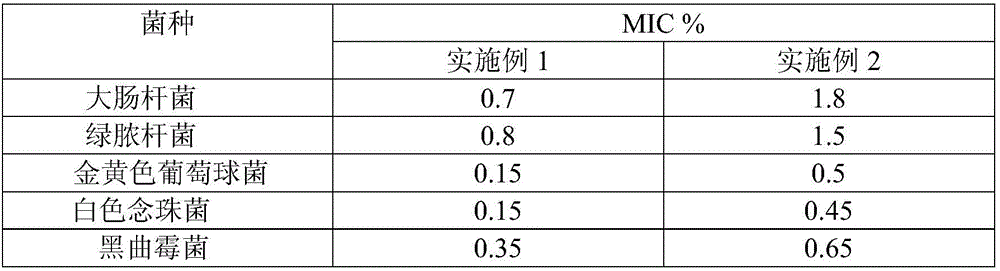

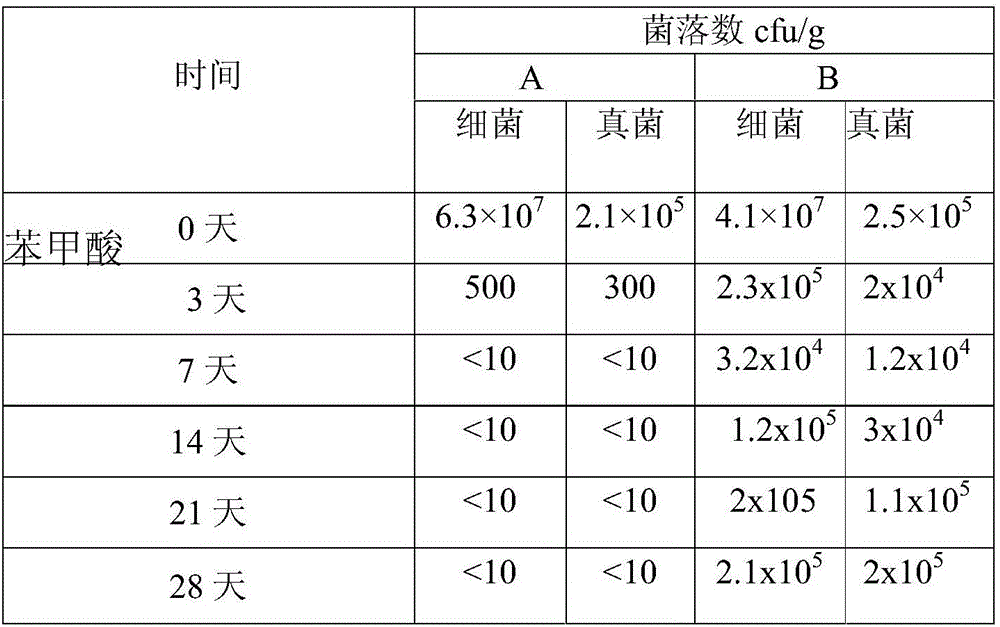

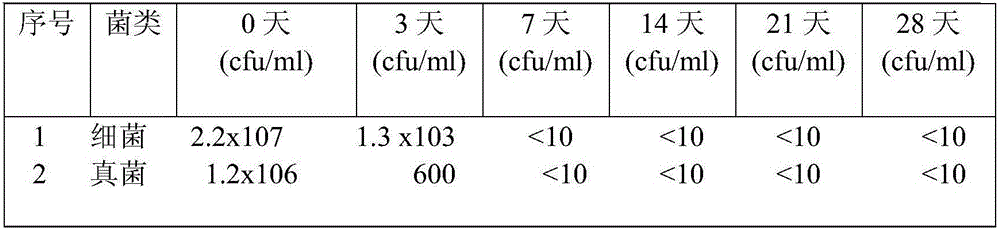

Embodiment 1

[0030] Add 150 grams of sorbitol and 1.5 grams of phosphoric acid to a 500 ml flask equipped with a vacuum dehydration device, nitrogen inlet pipe and water separator, heat to 150°C-175°C for dehydration under nitrogen, and keep the vacuum at 5000-6000pa for 100 minutes; Then, 132.5 grams of octanoic acid and 2.65 grams of potassium carbonate were added to the flask, and the process was protected by nitrogen. At the same time, it took 60 minutes to heat up to 190 ° C, and continued to stir and react at a pressure of 4000 to 5000 Pa. After 30 minutes, the temperature was raised to 210 ° C to continue the reaction; Acid value, when the acid value is less than 6.0mgKOH / g, cool down to stop the reaction; filter the product to obtain a transparent light yellow crude product, the acid value of the product is 4.3mgKOH / g, the saponification value is 208mgKOH / g, and the content of sorbitan monocaprylate 61.5% (by weight), 21.3% of isosorbide (two anhydrous sorbitan) octanoate, and the r...

Embodiment 2( example 1

[0032] Embodiment 2 (instance 1 contrast, do dehydration and esterification catalyst with the vitriol oil)

[0033] Add 150 grams of sorbitol and 1.5 grams of concentrated sulfuric acid to a 500 ml flask with a vacuum dehydration device, nitrogen input pipe and water separator, heat to 150°C-175°C for dehydration with nitrogen gas, and keep the vacuum at 5000-6000pa for reaction 100min; then, add 132.5 grams of octanoic acid into the flask, protect the process with nitrogen, and at the same time raise the temperature to 190°C for 60min, continue stirring and reacting at 4000-5000pa, and continue to react after 30min at 210°C; then measure the acid value every 20min, when the acid value When the temperature is less than 6.0mgKOH / g, the temperature is lowered to stop the reaction; the product is filtered to obtain a brown crude product with peculiar smell. The acid value of the product is 3.2mgKOH / g, the saponification value is 193mgKOH / g, the content of sorbitan monocaprylate i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Saponification value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com