Waterproof coating prepolymer prepared based on polyurethane degradation product, and preparation method and application thereof

A technology for degradation products and waterproof coatings, applied in the direction of polyurea/polyurethane coatings, coatings, plastic recycling, etc., can solve problems such as high price, and achieve the effects of solving environmental problems, high promotion value, and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

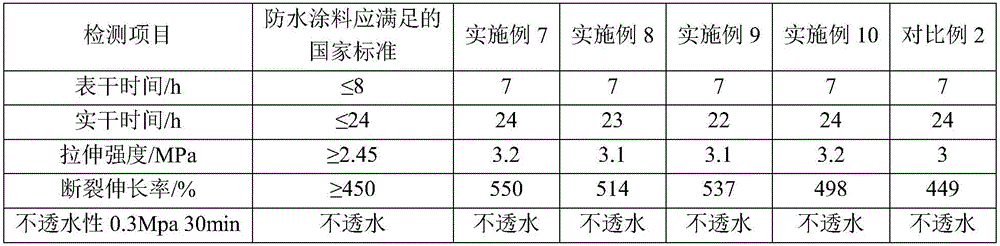

Examples

Embodiment 1

[0039] S1. Break 100 parts of polyurethane elastomer product leftovers into the reaction kettle together with 10 parts of ethylene glycol and 1 part of catalyst potassium acetate;

[0040] S2. Heating, controlling the reaction temperature to 180° C., the reaction time is 3 hours, and discharging to obtain a polyurethane degradation product.

Embodiment 2

[0042] S1. 100 parts of waste polyurethane elastomer products are broken, and 5 parts of ethylene glycol, 10 parts of propylene glycol, and 3 parts of catalyst ethylenediamine are added to the reactor;

[0043] S2. Heating, controlling the reaction temperature to 230° C., the reaction time is 1 hour, and discharging to obtain a polyurethane degradation product.

Embodiment 3

[0045] S1. Break 100 parts of polyurethane elastomer product leftovers into the reaction kettle together with 10 parts of diethylene glycol, 5 parts of butanediol, and 2 parts of catalyst ethanolamine;

[0046] S2. Heating, controlling the reaction temperature to 200° C., the reaction time is 2 hours, and discharging to obtain a polyurethane degradation product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com