Bio-based photosensitive polyurethane resin, and self-repairing coating made of resin

A polyurethane resin, bio-based dimeramine technology, used in polyurea/polyurethane coatings, coatings, etc., to achieve high curing efficiency, improve repair efficiency, and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

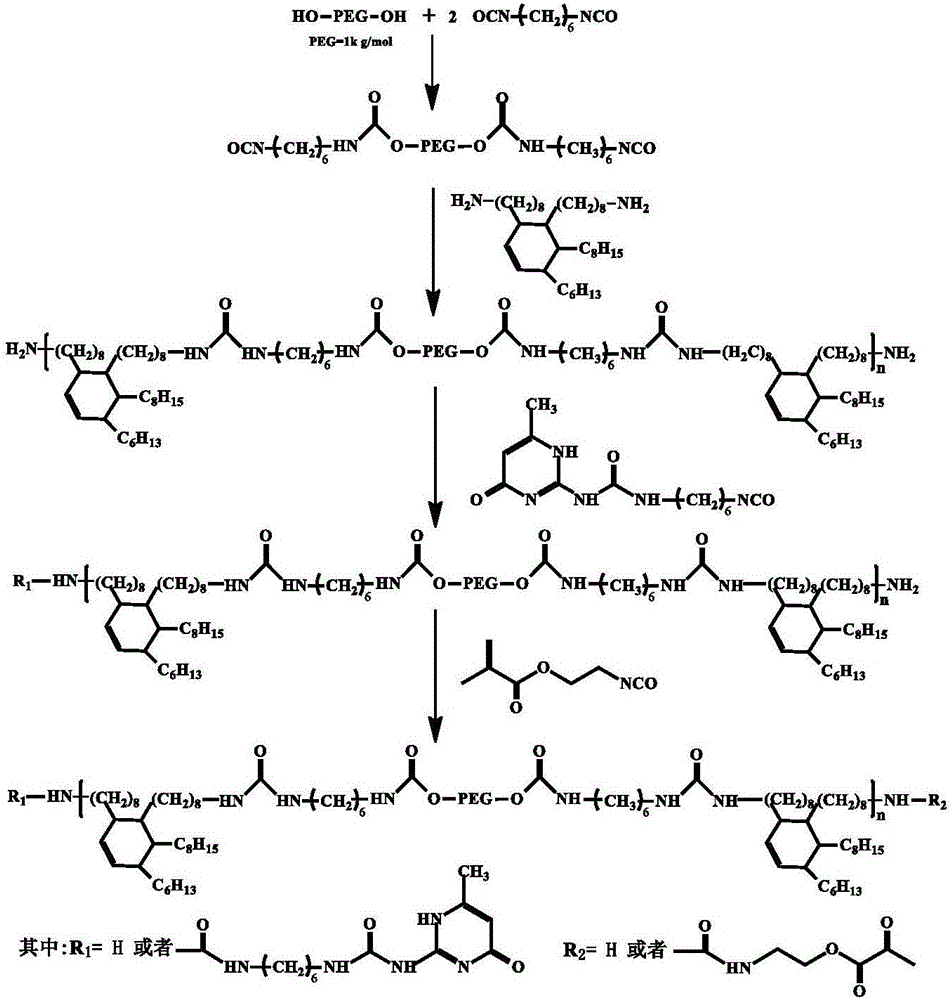

Method used

Image

Examples

Embodiment 1

[0029] (1) Synthesis of bio-based photosensitive polyurethane resin: First, add 50.000g PEG-1000, 0.401g dilauric acid di Butyltin and 60g of anhydrous chloroform were stirred to form a clear solution; at the same time, a mixture of 16.820g of hexamethylene diisocyanate and 30g of anhydrous chloroform was slowly added dropwise to the flask, and reacted at 50°C for 7h. Continue to drop 31.980 g of Priamine 1074 and 40 g of anhydrous chloroform mixture, and react at 25° C. for 6 h to obtain a bio-based polyurethane solution with an amino terminal. Secondly, a mixture of 4.786g UPy-NCO and 100g anhydrous chloroform was slowly added dropwise, and the reaction was kept at 25°C for 6h to obtain a self-healing bio-based polyurethane solution. Finally, slowly drop a mixture of 4.655g isocyanoethyl methacrylate, 0.093g hydroquinone, and 30g anhydrous chloroform, keep the reaction at 30°C for 6 hours, and rotate to evaporate the excess chloroform solution , to obtain a bio-based photos...

Embodiment 2

[0032](1) Synthesis of bio-based photosensitive polyurethane resin: First, add 50.000g PEG-1000, 0.401g dilauric acid di Butyltin and 60g of anhydrous chloroform were stirred to form a clear solution; at the same time, a mixture of 16.820g of hexamethylene diisocyanate and 30g of anhydrous chloroform was slowly added dropwise to the flask, and reacted at 50°C for 7h. Continue to drop 31.980 g of Priamine 1074 and 40 g of anhydrous chloroform mixture, and react at 25° C. for 6 h to obtain a bio-based polyurethane solution with an amino terminal. Secondly, a mixture of 5.983g UPy-NCO and 120g anhydrous chloroform was slowly added dropwise, and kept for 6 hours at 25°C to obtain a self-healing bio-based polyurethane solution. Finally, slowly drop a mixture of 3.879g of isocyanoethyl methacrylate, 0.093g of hydroquinone, and 25g of anhydrous chloroform, keep the reaction at 30°C for 6 hours, and rotate to evaporate the excess chloroform , to obtain a bio-based photosensitive poly...

Embodiment 3

[0036] (1) Synthesis of bio-based photosensitive polyurethane resin: First, add 50.000g PEG-1000, 0.401g dilauric acid di Butyltin and 60g of anhydrous chloroform were stirred to form a clear solution; at the same time, a mixture of 16.820g of hexamethylene diisocyanate and 30g of anhydrous chloroform was slowly added dropwise to the flask, and reacted at 50°C for 7h. Continue to drop 31.980 g of Priamine 1074 and 40 g of anhydrous chloroform mixture, and react at 25° C. for 6 h to obtain a bio-based polyurethane solution with an amino terminal. Secondly, a mixture of 7.179g of UPy-NCO and 140g of anhydrous chloroform was slowly added dropwise, and kept for 6 hours at 25°C to obtain a self-healing bio-based polyurethane solution. Finally, slowly drop a mixture of 3.103g isocyanoethyl methacrylate, 0.093g hydroquinone, and 20g anhydrous chloroform, keep the reaction at 30°C for 6 hours, and rotate to evaporate the excess chloroform solution , to obtain a bio-based photosensiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com