A polyurethane rigid foam-aerogel composite flame-retardant thermal insulation material and its preparation method

A rigid foam and composite flame-retardant technology, applied in coatings and other directions, can solve problems such as limited application environment, low flame-retardant performance, and decreased thermal insulation performance, and achieve simple process operation, excellent flame-retardant performance, and enhanced bonding force Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

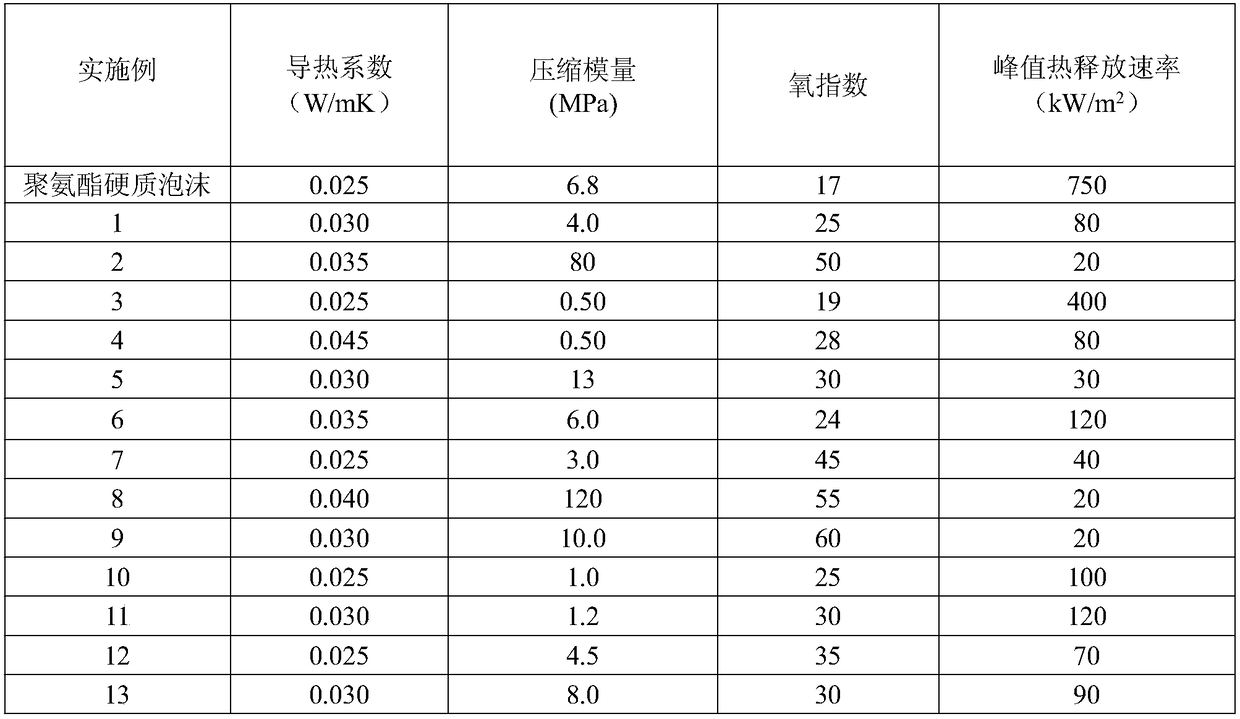

Examples

Embodiment 1

[0030] A preparation method of polyurethane rigid foam-aerogel composite flame-retardant insulation material, comprising the following steps:

[0031] Step 1. Heat and dissolve 1 g of polyvinyl alcohol (Mw31000-50000, degree of alcoholysis 99%) in 100 mL of deionized water, then add 15 g of montmorillonite and stir to obtain a colloid;

[0032] Step 2: Apply the obtained colloid evenly to the surface of rigid polyurethane foam with a thickness of 10mm, then quickly freeze at -78°C until the ice crystals grow completely, and vacuum dry at room temperature until completely freeze-dried to obtain rigid polyurethane foam-air condensation Glue composite flame-retardant insulation material; wherein the airgel is polyvinyl alcohol-montmorillonite airgel.

Embodiment 2

[0034] A preparation method of polyurethane rigid foam-aerogel composite flame-retardant insulation material, comprising the following steps:

[0035] Step 1. Heat and dissolve 10g of sodium alginate in 100mL of deionized water, then add 5g of vermiculite and stir at 1000r / min to obtain a colloid;

[0036] Step 2. Apply the obtained colloid evenly to the surface of rigid polyurethane foam with a thickness of 1mm, then quickly freeze at -56°C until the ice crystals grow completely, and vacuum dry at room temperature until completely freeze-dried to obtain rigid polyurethane foam-air condensation Glue composite flame retardant insulation material; the airgel is sodium alginate-vermiculite airgel.

Embodiment 3

[0038] A preparation method of polyurethane rigid foam-aerogel composite flame-retardant insulation material, comprising the following steps:

[0039] Step 1. Heat and dissolve 2g of pectin in 100mL of deionized water, then add 1g of kaolin and stir at 1200r / min to obtain a colloid;

[0040] Step 2: Apply the obtained colloid evenly to the surface of rigid polyurethane foam with a thickness of 5mm, then quickly freeze at -196°C (liquid nitrogen bath) until the ice crystals grow completely, and vacuum dry at room temperature until completely freeze-dried to obtain polyurethane rigid foam. Quality foam-aerogel composite flame-retardant thermal insulation material; wherein the airgel is pectin-kaolin aerogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com