Moisture-absorbing and heating yarn and preparation and dyeing method thereof

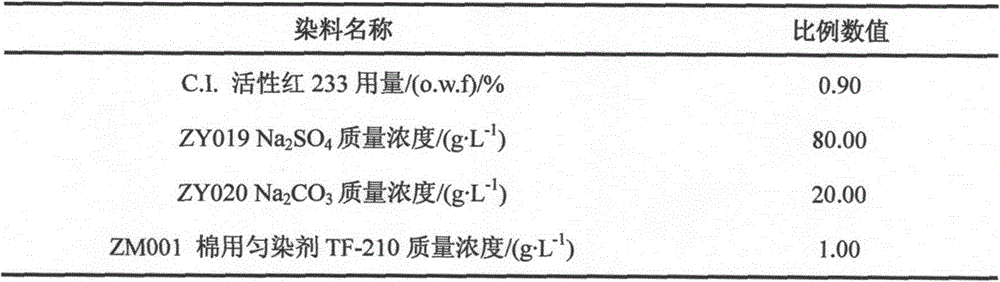

A technology of moisture absorption and heating, yarn, applied in the direction of dyeing, yarn, rayon manufacturing, etc., can solve the problems of poor dyeing uniformity, complicated procedures, etc., achieve the effect of reducing dyeing cost, high dyeing uniformity, and reducing dyeing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A hygroscopic and heating yarn, which is composed of 20% modified coffee charcoal polyester staple fiber and 80% viscose staple fiber by mass fraction, wherein the total amount of modified coffee charcoal polyester staple fiber and viscose staple fiber is 100wt %. The section of the modified coffee charcoal polyester staple fiber is a hollow structure.

[0049] The viscose staple fiber has a length of 38mm, a denier of 1.33dtex, a breaking strength of 2.81cN / dtex, a breaking elongation of 19.1%, and an initial modulus of 49.29cN / dtex.

[0050] The preparation method of the described hygroscopic and heating yarn is:

[0051] 1. Preparation of modified coffee charcoal polyester staple fiber:

[0052] (1) Preparation of coffee charcoal

[0053] Use discarded coffee grounds, mix it with 50% mass concentration of phosphoric acid in a mass ratio of 2:1, soak at 100°C for 2 hours, take the impregnated coffee charcoal, and first dry it at 150°C for 3 hours. Then raise the t...

Embodiment 2

[0091] A multi-hygroscopic and heat-generating yarn, which is composed of 30% modified coffee charcoal polyester staple fiber and 70% viscose staple fiber in mass fraction, wherein the total amount of modified coffee charcoal polyester staple fiber and viscose staple fiber is 100% by weight. The section of the modified coffee charcoal polyester staple fiber is a hollow structure.

[0092] The viscose staple fiber has a length of 38mm, a denier of 1.33dtex, a breaking strength of 2.81cN / dtex, a breaking elongation of 19.1%, and an initial modulus of 49.29cN / dtex.

[0093] The preparation method of the described hygroscopic and heating yarn is:

[0094] 1. Preparation of modified coffee charcoal polyester staple fiber:

[0095] (1) Preparation of coffee charcoal

[0096] Use discarded coffee grounds, mix it with 50% mass concentration of phosphoric acid in a mass ratio of 2:1, soak at 100°C for 2 hours, take the impregnated coffee charcoal, and first dry it at 180°C for 1 hou...

Embodiment 3

[0133] A hygroscopic and heating yarn, composed of 40% modified coffee charcoal polyester staple fiber and 60% viscose staple fiber by mass fraction, wherein the total amount of modified coffee charcoal polyester staple fiber and viscose staple fiber is 100wt %. The section of the modified coffee charcoal polyester staple fiber is a hollow structure.

[0134] The viscose staple fiber has a length of 38mm, a denier of 1.33dtex, a breaking strength of 2.81cN / dtex, a breaking elongation of 19.1%, and an initial modulus of 49.29cN / dtex.

[0135] The preparation method of the described hygroscopic and heating yarn is:

[0136] 1. Preparation of modified coffee charcoal polyester staple fiber:

[0137] (1) Preparation of coffee charcoal

[0138] Use discarded coffee grounds, mix it with 50% mass concentration of phosphoric acid at a mass ratio of 2:1, soak at 100°C for 2 hours, take the impregnated coffee charcoal, and first dry it at 170°C for 2 hours, Then raise the temperatur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com