Emergent temperature control method and device in animal pyrolysis carbonization process

A technology of pyrolysis carbonization and temperature control device, which is applied to the method of incinerating corpses, combustion methods, incinerators, etc., and can solve problems such as high temperature, inconvenient operation, and pathogenic bacteria infection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

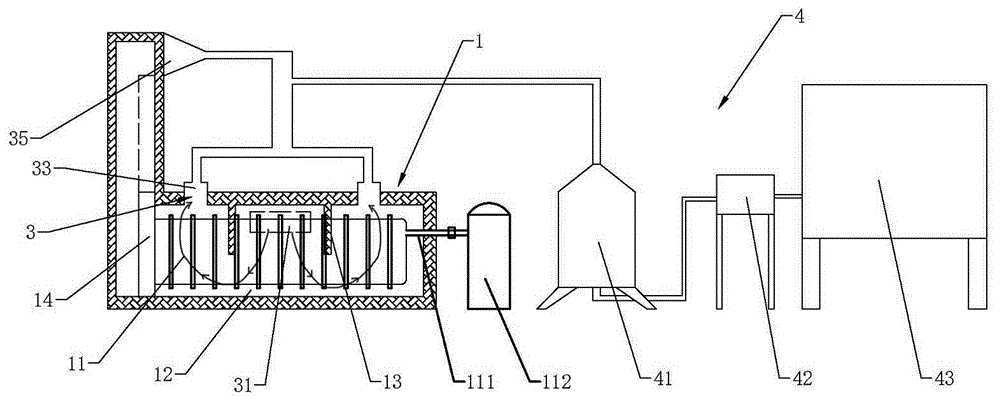

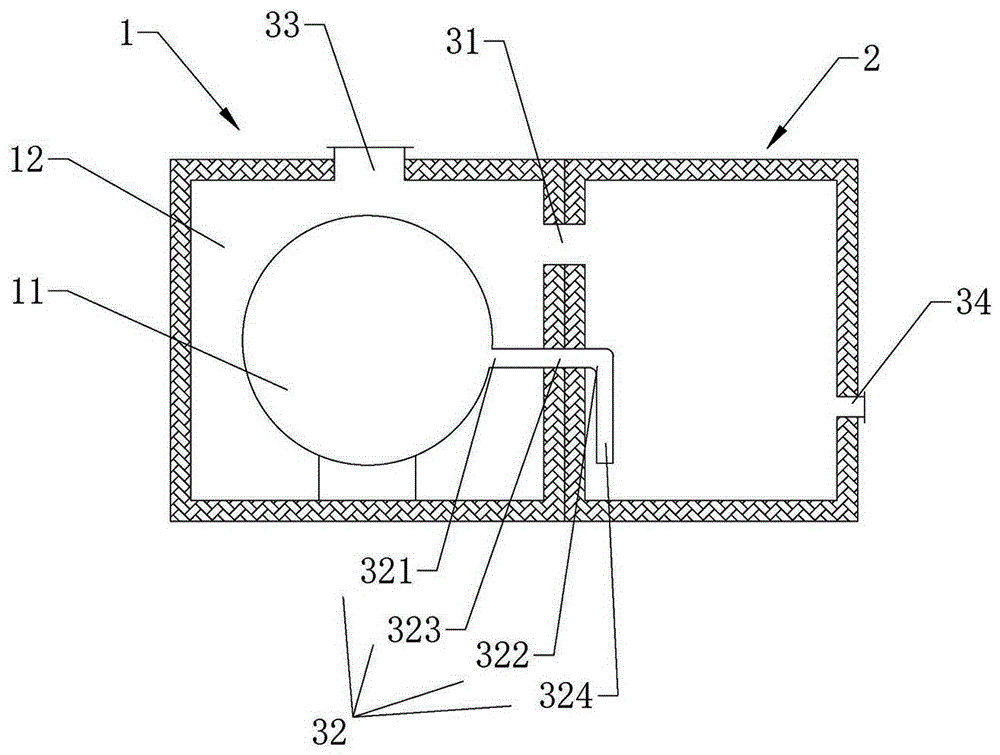

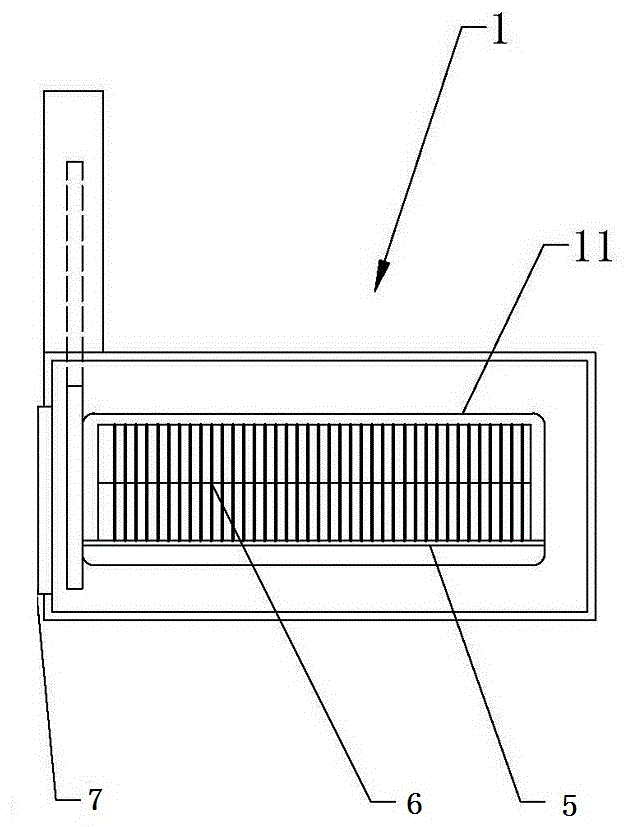

[0092] The emergency temperature control method in the pyrolysis and carbonization process of animals is characterized in that: during the pyrolysis and carbonization process, when the temperature in the combustion chamber 2 exceeds 1000 degrees Celsius, helium gas is introduced into the carbonization tank 11 to reduce the temperature in the carbonization tank 11. Pyrolysis gas concentration. The combustion chamber temperature was reduced by 200 °C within 10 min.

[0093] The pyrolytic carbonization treatment process is carried out in the carbonization chamber 1. The carbonization process includes pyrolytic carbonization treatment of dead animal corpses under the conditions of oxygen isolation, normal pressure and 500 ° C; The gas is automatically output to the combustion chamber 2 and burned at 950°C for 2s. The high-temperature flue gas generated by the combustion provides energy to support pyrolysis and carbonization, and realizes the heat energy recovery and utilization of...

Embodiment 2

[0095] Same as the first embodiment, the difference is that liquid nitrogen is injected into the carbonization tank 11 when the temperature in the combustion chamber 2 exceeds 1200 degrees. The combustion chamber temperature was lowered by 300°C within 10 minutes.

[0096] The pyrolytic carbonization treatment process is carried out in the carbonization chamber 1. The carbonization process includes pyrolytic carbonization treatment of dead animal corpses under the conditions of oxygen isolation, normal pressure and 600°C; The gas is automatically output to the combustion chamber 2 and burned at 1300°C for 2s. The high-temperature flue gas generated by the combustion provides energy to support pyrolysis and carbonization, and realizes the recovery and utilization of heat energy of the pyrolysis gas.

Embodiment 3

[0098] Same as the second embodiment, the difference is that when the temperature in the combustion chamber 2 exceeds 1000 degrees Celsius, nitrogen monoxide is introduced into the carbonization tank 11 to reduce the pyrolysis gas concentration in the carbonization tank 11 . The combustion chamber temperature was reduced by 150°C within 10 minutes.

[0099] The pyrolytic carbonization treatment process is carried out in the carbonization chamber 1. The carbonization process includes the pyrolytic carbonization treatment of the carcasses of sick and dead animals under the conditions of oxygen isolation, normal pressure and 300°C; The gas is automatically output to the combustion chamber 2 and burned at 800°C for 2s. The high-temperature flue gas generated by the combustion provides energy to support pyrolysis and carbonization, and realizes the heat energy recovery and utilization of the pyrolysis gas.

[0100] The inventors have found that the properties of the pyrolysis cha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com