Municipal sewage sand removing device and method

A technology of urban sewage and water chambers, applied in separation methods, chemical instruments and methods, dehydration/drying/thickened sludge treatment, etc., can solve the problems of incomplete treatment, large floor area, lengthy process, etc., and achieve sand removal Excellent effect, reduced floor space and improved environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

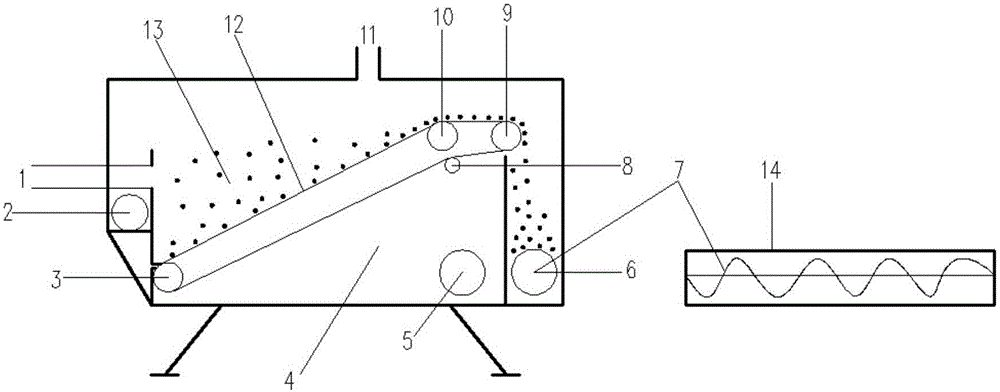

[0020] The equipment of the present invention is specifically shown in figure 1 , the specific operation steps have been described in detail in the content of the invention, and will not be repeated here. The pre-filter is mainly divided into three parts: the pre-filtration water chamber, the filtered water chamber and the mud sand chamber. Raw water enters the pre-filter water chamber from the water inlet, enters the after-filter water chamber after being filtered by the filter cloth, and finally the sewage is discharged to the drainage channel through the water outlet. The rotating filter cloth scrapes the filtered mud and sand to the mud sand chamber through the brush, and then squeezes the dewatering parts through the filtered matter for dehydration, and finally discharges the mud and sand from the pre-filter.

[0021] The present invention has been tested and researched in a sewage plant in Beijing. The operating conditions: the length, width and height of the equipment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com