Flame-retardant polyurethane rigid foam plastic and preparation method and application thereof

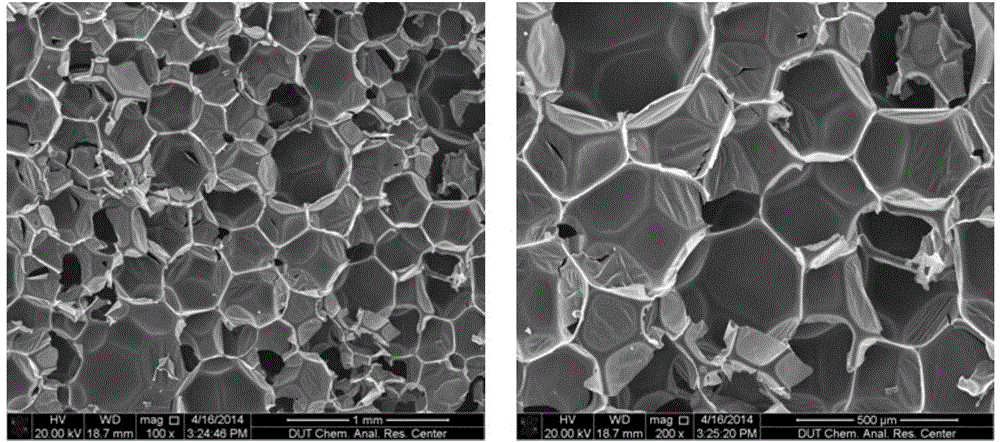

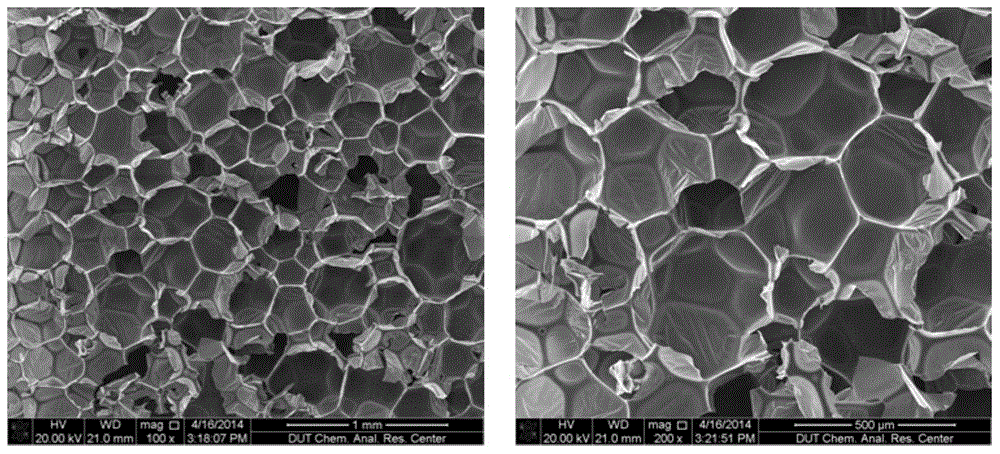

A rigid foam plastic and polyurethane technology, applied in the field of polymer materials, can solve the problems of insufficient flame retardant effect, poor comprehensive performance, and great harm to human body, and achieve the effects of uniform cells, good mechanical properties, and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

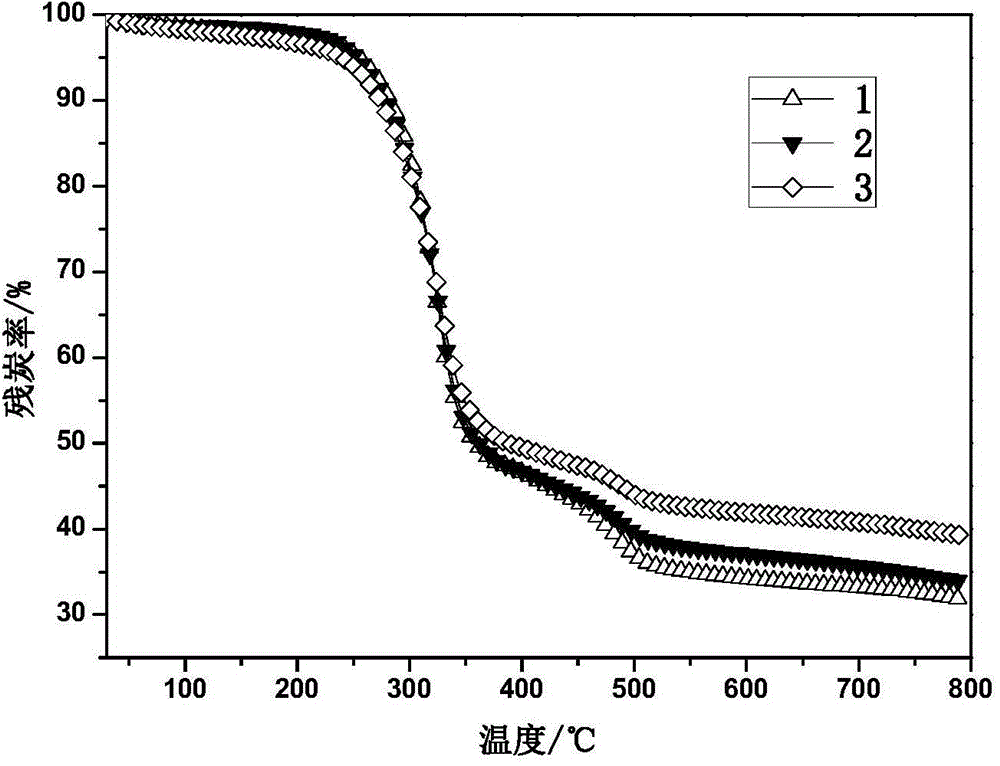

[0048] Weigh the polyethylene oxide polyol, flame retardant, stannous octoate, silicone oil, n-pentane (if the foaming agent is already contained in the commercially available polyol, it can be omitted), put it into the mixing tank, stir for 5 minutes to make it Mix evenly to obtain combined polyol (material A). Weigh polymethylene polyphenyl polyisocyanate (material B) and add it to material A, stir rapidly for 20 seconds to make it evenly mixed, then pour the above reaction solution into a mold for foaming, and mature at room temperature for 20 hours to obtain flame-retardant polyurethane Rigid foam. The LOI value is 30.

[0049] Among them, the flame retardant is: 40 parts of ammonium polyphosphate, 25 parts of coated red phosphorus.

Embodiment 2

[0051] Weigh the polypropylene oxide polyol, flame retardant, stannous octoate, silicone oil, and fluorodichloroethane (if the commercially available polyol already contains foaming agent, it can be omitted), put it into the mixing tank, and stir for 25 minutes Make it mix uniformly, obtain combination polyol (A material). Weigh polymethylene polyphenyl polyisocyanate (material B) and add it to material A, stir rapidly for 35 seconds to make it evenly mixed, then pour the above reaction solution into a mold for foaming, and mature at room temperature for 20 hours to obtain flame-retardant polyurethane Rigid foam. The LOI value is 32.

[0052] Wherein the flame retardant is: 10 parts of hollow glass microspheres, 25 parts of coated red phosphorus.

Embodiment 3

[0054] Weigh polyhexamethylene adipate diol, flame retardant, stannous octoate, silicone oil, fluorodichloroethane (if the commercially available polyol already contains foaming agent, do not need to add it), put it into the mixing tank , and stirred for 5 minutes to make it evenly mixed to obtain a combined polyol (material A). Weigh polymethylene polyphenyl polyisocyanate (B material). The materials A and B were sprayed with spraying equipment, and cured at room temperature for 18 hours to obtain a flame-retardant polyurethane rigid foam material. The LOI value is 32.

[0055] Among them, the flame retardant is: 15 parts of phenyl phosphite, 35 parts of coated red phosphorus.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com