Method for enhancing interfacial properties of SMA (styrene maleic anhydride) reinforced resin intelligent composite materials

A technology for strengthening resin-based and composite materials, which is applied in the field of improving the interface performance of SMA-reinforced resin-based intelligent composite materials, and can solve problems such as fiber material damage, SMA wire surface nano-particle shedding, and dynamic performance degradation, so as to achieve not easy to fall off, improve Industrial production process, the effect of improving interface performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in more detail below with examples in conjunction with the accompanying drawings.

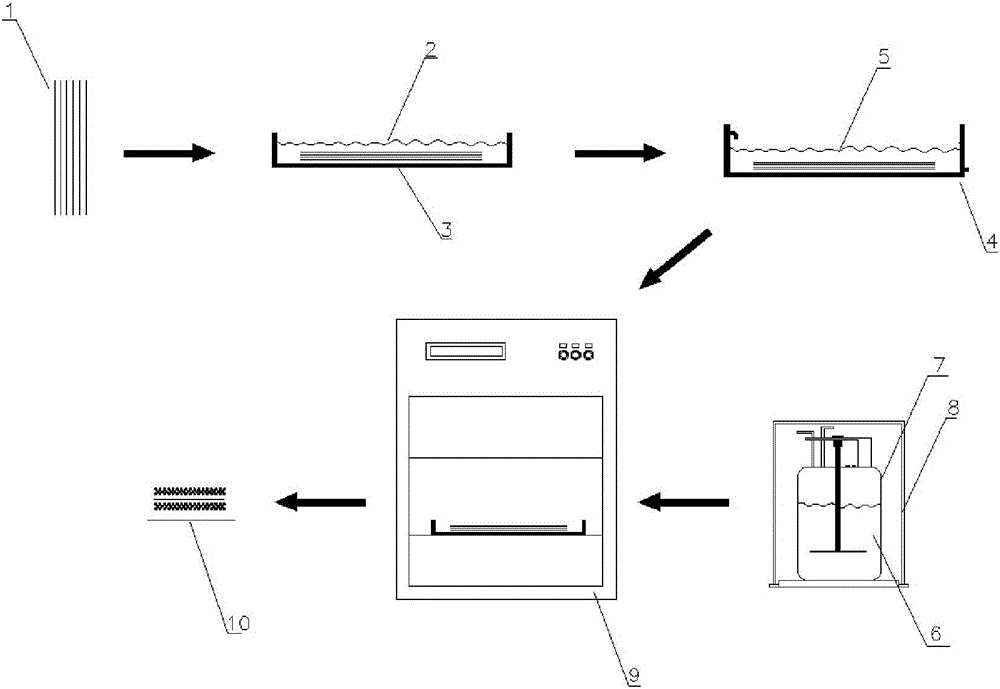

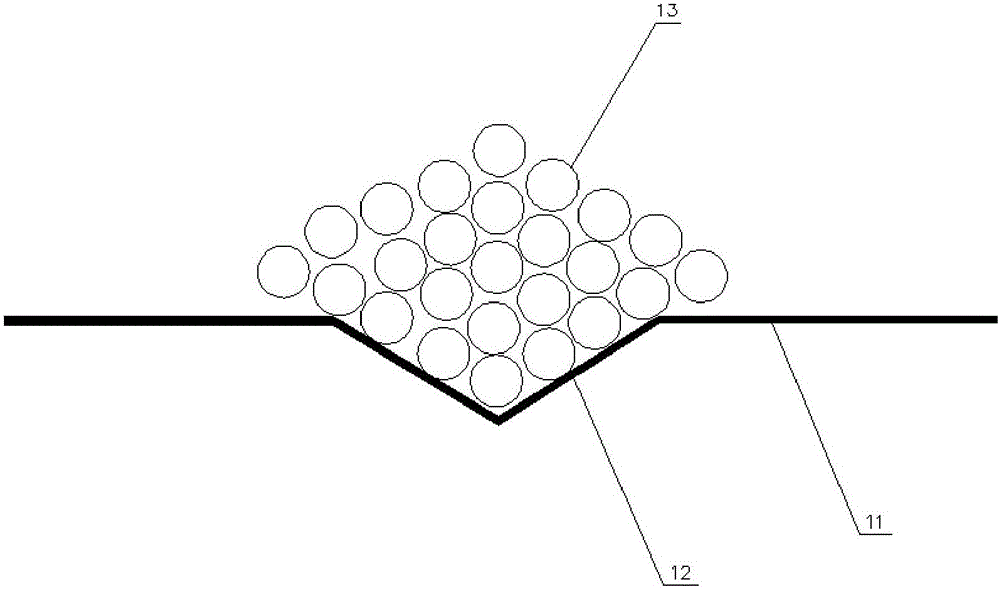

[0020] combine figure 1 , cut the SMA wire 1 into the required length, put it into the cleaning tank and wash it with clean water, and then put it into the industrial chemical reaction tank 3 filled with the concentrated nitric acid solution 2. This process should ensure that the nitric acid solution will completely clean the SMA wire. Submerged; the soaking time is 8h, the SMA wire is taken out, and rinsed with clear water 5 in the flow washing pool 4; 2 The particles are put into the isopropanone solution 6, and the mixed solution is stirred by a vacuum hydraulic lift mixer 7, the stirring time is set to 3h, and the stirring speed is set to 100r / min. This process is dispersed in the ultrasonic disperser 8; Deposition (PVD) method will nano-SiO 2 Particles covered on the surface of SMA: put the nitric acid-treated SMA wire into the nano-SiO 2 I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com