Mildew-proof antibacterial EVA (ethylene-vinyl acetate) or PEVA (polyethylene vinyl acetate) film

A technology of anti-mildew and anti-bacterial film, which is applied in the field of anti-mold and anti-bacterial EVA or PEVA film, can solve the problems of endangering people's health, mildew, affecting the tensile properties and tearing properties of the film, and achieves excellent anti-mold and anti-bacterial properties, The effect of high impact strength and tear strength, broad application prospects and market demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

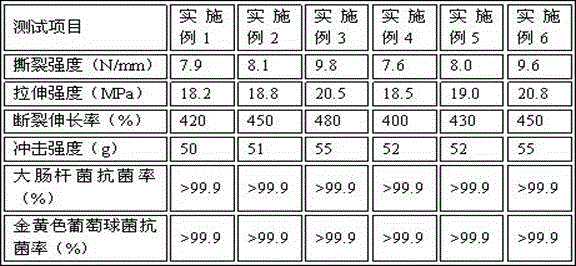

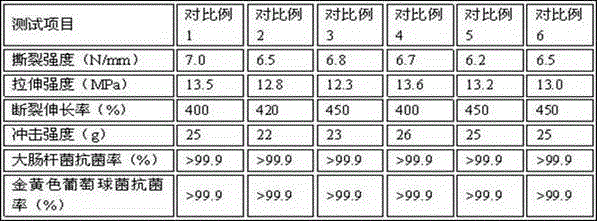

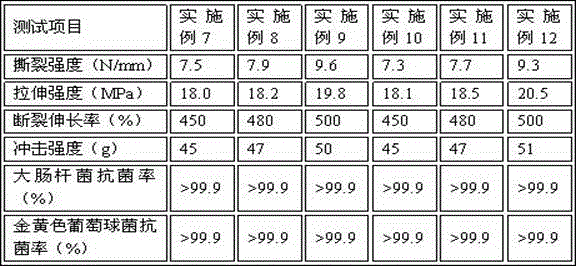

Examples

Embodiment 1

[0019] The EVA film of this embodiment is prepared by cast film forming process. The barrel of the extruder is divided into a feeding section, a plasticizing section and a homogenizing section. The temperature of the feeding section is 150-180° C. ~220°C, the temperature of the homogenization section is 220~240°C; the temperature in the middle of the T-shaped molding die is 230°C, the temperature at both ends is 235°C, and the roll surface temperature of the casting cooling roll is 60°C.

[0020] The raw material formula of EVA film is as follows:

[0021] Ethylene-vinyl acetate copolymer (EVA): 100 parts by weight;

[0022] Low-density polyethylene (LDPE): 10 parts by weight;

[0023] Polyethylene grafted GMA: 0.5 parts by weight;

[0024] Zinc pyrithione: 1.5 parts by weight;

[0025] N-(2-mercaptoethyl)acrylamide: 5.0 parts by weight;

[0026] Triallyl isocyanate: 1.5 parts by weight;

[0027] 2-vinyl-4,6-diamino-1,3,5-triazine: 1.0 parts by weight.

Embodiment 2

[0029] The EVA film of this embodiment is prepared by cast film forming process. The barrel of the extruder is divided into a feeding section, a plasticizing section and a homogenizing section. The temperature of the feeding section is 150-180° C. ~220°C, the temperature of the homogenization section is 220~240°C; the temperature in the middle of the T-shaped molding die is 230°C, the temperature at both ends is 235°C, and the roll surface temperature of the casting cooling roll is 60°C.

[0030] The raw material formula of EVA film is as follows:

[0031] Ethylene-vinyl acetate copolymer (EVA): 100 parts by weight;

[0032] Low-density polyethylene (LDPE): 20 parts by weight;

[0033] Polyethylene grafted GMA: 1.0 parts by weight;

[0034] Zinc pyrithione: 1.5 parts by weight;

[0035] N-(4-mercaptophenyl)acrylamide: 3.0 parts by weight;

[0036] Triallyl isocyanate: 2.0 parts by weight;

[0037] 2-vinyl-4,6-diamino-1,3,5-triazine: 1.5 parts by weight.

Embodiment 3

[0039] The EVA film of this embodiment is prepared by cast film forming process. The barrel of the extruder is divided into a feeding section, a plasticizing section and a homogenizing section. The temperature of the feeding section is 150-180° C. ~220°C, the temperature of the homogenization section is 220~240°C; the temperature in the middle of the T-shaped molding die is 230°C, the temperature at both ends is 235°C, and the roll surface temperature of the casting cooling roll is 60°C.

[0040] The raw material formula of EVA film is as follows:

[0041] Ethylene-vinyl acetate copolymer (EVA): 100 parts by weight;

[0042] Low-density polyethylene (LDPE): 15 parts by weight;

[0043] Polyethylene grafted GMA: 0.8 parts by weight;

[0044] Zinc pyrithione: 1.5 parts by weight;

[0045] Maleic acid mono-2-mercaptoethylamide: 4.0 parts by weight;

[0046] Triallyl isocyanate: 1.8 parts by weight;

[0047] 2-vinyl-4,6-diamino-1,3,5-triazine: 1.2 parts by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com