Resourceful treatment method of chromium-containing aluminum mud

A treatment method and a resource-based technology, applied in the direction of improving process efficiency, etc., to achieve the effect of recycling and reducing solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

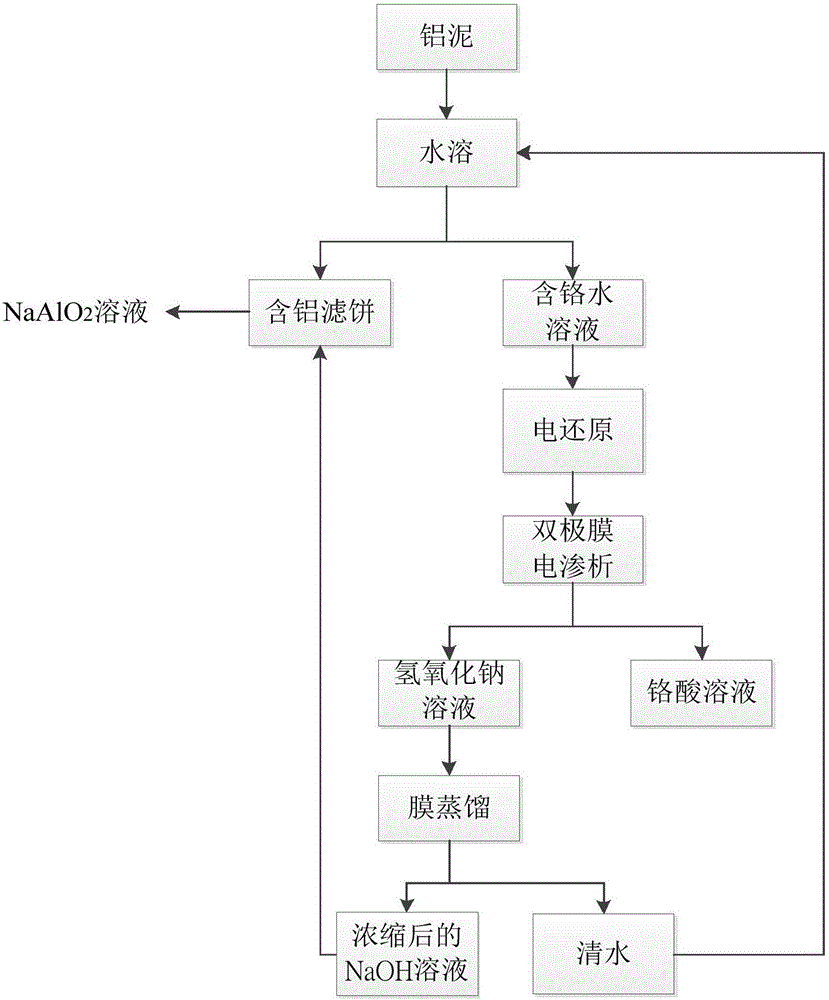

Image

Examples

Embodiment 1

[0039] The waste residue produced during the production of sodium dichromate in a chromium salt factory has a moisture content of about 60% (mass fraction), and the dry aluminum sludge mainly contains Al 2 o 3 、Cr 2 o 3 、Na 2 CrO 4 , SiO 2 and Fe 2 o 3 Wait.

[0040] (1) Water-soluble: add water to the waste residue (mass ratio of waste residue to water is 1:3), stir and react at 70°C for 1 hour, wash with water repeatedly for 3 times, and filter to obtain chromium (VI)-containing aqueous solution and aluminum-containing filter cake.

[0041] (2) Electroreduction: the aqueous solution containing chromium (VI) is electroreduced to reduce hexavalent chromium to trivalent; electroreduction parameters: the anode electrode is Ru-Ir / Ti, the cathode is Ti plate, and the current density is 150A / m 2 , an ion exchange membrane is added to the electrolyzer to separate the anode and cathode.

[0042] (3) Bipolar membrane electrodialysis: the aqueous solution containing chromium (...

Embodiment 2

[0053] The waste residue produced during the production of sodium dichromate in a chromium salt factory has a moisture content of about 60% (mass fraction), and the dry aluminum sludge mainly contains Al 2 o 3 、Cr 2 o 3 、Na 2 CrO 4 , SiO 2 and Fe 2 o 3 Wait.

[0054] (1) Water-soluble: add water to the waste residue (the mass ratio of waste residue to water is 1:3), stir and react at 70°C for 1 hour, wash with water three times, and filter to obtain chromium (VI)-containing aqueous solution and aluminum-containing filter cake.

[0055] (2) Electroreduction: the aqueous solution containing chromium (VI) is electroreduced to reduce hexavalent chromium to trivalent; electroreduction parameters: the anode electrode is Ru-Ir / Ti, the cathode is Ti plate, and the current density is 150A / m 2 , an ion exchange membrane is added to the electrolyzer to separate the anode and cathode.

[0056] (3) Bipolar membrane electrodialysis: the aqueous solution containing chromium (III) is...

Embodiment 3

[0060] The waste residue produced during the production of sodium dichromate in a chromium salt factory has a moisture content of about 60% (mass fraction), and the dry aluminum sludge mainly contains Al 2 o 3 、Cr 2 o 3 、Na 2 CrO 4 , SiO 2 and Fe 2 o 3 Wait.

[0061] (1) Water-soluble: add water to the waste residue (mass ratio of waste residue to water is 1:3), stir and react at 60°C for 1 hour, wash with water repeatedly for 3 times, and filter to obtain chromium (VI)-containing aqueous solution and aluminum-containing filter cake.

[0062] (2) Electroreduction: the aqueous solution containing chromium (VI) is electroreduced to reduce hexavalent chromium to trivalent; electroreduction parameters: the anode electrode is Ru-Ir / Ti, the cathode is Ti plate, and the current density is 150A / m 2 , an ion exchange membrane is added to the electrolyzer to separate the anode and cathode.

[0063] (3) Bipolar membrane electrodialysis: the aqueous solution containing chromium (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com