Hollow steel continuous pumping rod resistant to H2S corrosion

A technology of sucker rod and hollow steel, which is applied in the direction of drill pipe, drilling equipment, earthwork drilling and production, etc., can solve the problem of oil field consumption such as alarming, achieve good H2S stress corrosion cracking resistance, high safety and reliability, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] an anti-H 2 The corroded hollow coiled sucker rod 1 is the whole coiled tubing. The continuous sucker rod 1 is a whole coiled tubing that can be wound on the reel 2 and has no coupling. The length of the entire coiled tubing is ≥ 61m, the diameter is 25.4-88.9mm, the yield strength is ≥ 621MPa, the tensile strength is ≥ 689Mpa, and the corrosion resistance to hydrogen sulfide: the sulfur resistance performance is in accordance with the NACE0177-2005 standard and the A method is used at 85 % above the nominal yield strength of the sample under the load after 720 hours without cracking.

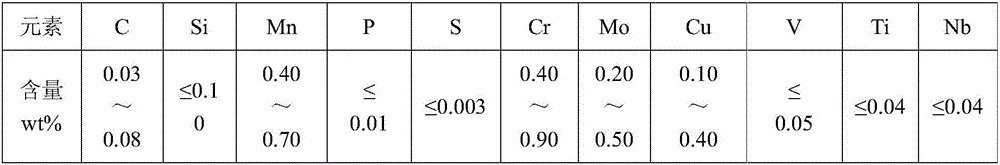

[0015] The manufacturing process of the continuous sucker rod of the present invention is as follows: melting and forging into slabs according to the chemical composition in Table 1; using TMCP process, the slabs with the above components are subjected to rough rolling and finish rolling at a certain temperature to make steel coils ;The steel coil is slit into the required steel strip,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com