Oil and gas field drilling waste mud treatment device

A waste mud and treatment device technology, applied in water/sludge/sewage treatment, sludge treatment through temperature control, dehydration/drying/thickened sludge treatment, etc. Problems such as too much material, to achieve the effect of low production cost, small footprint and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

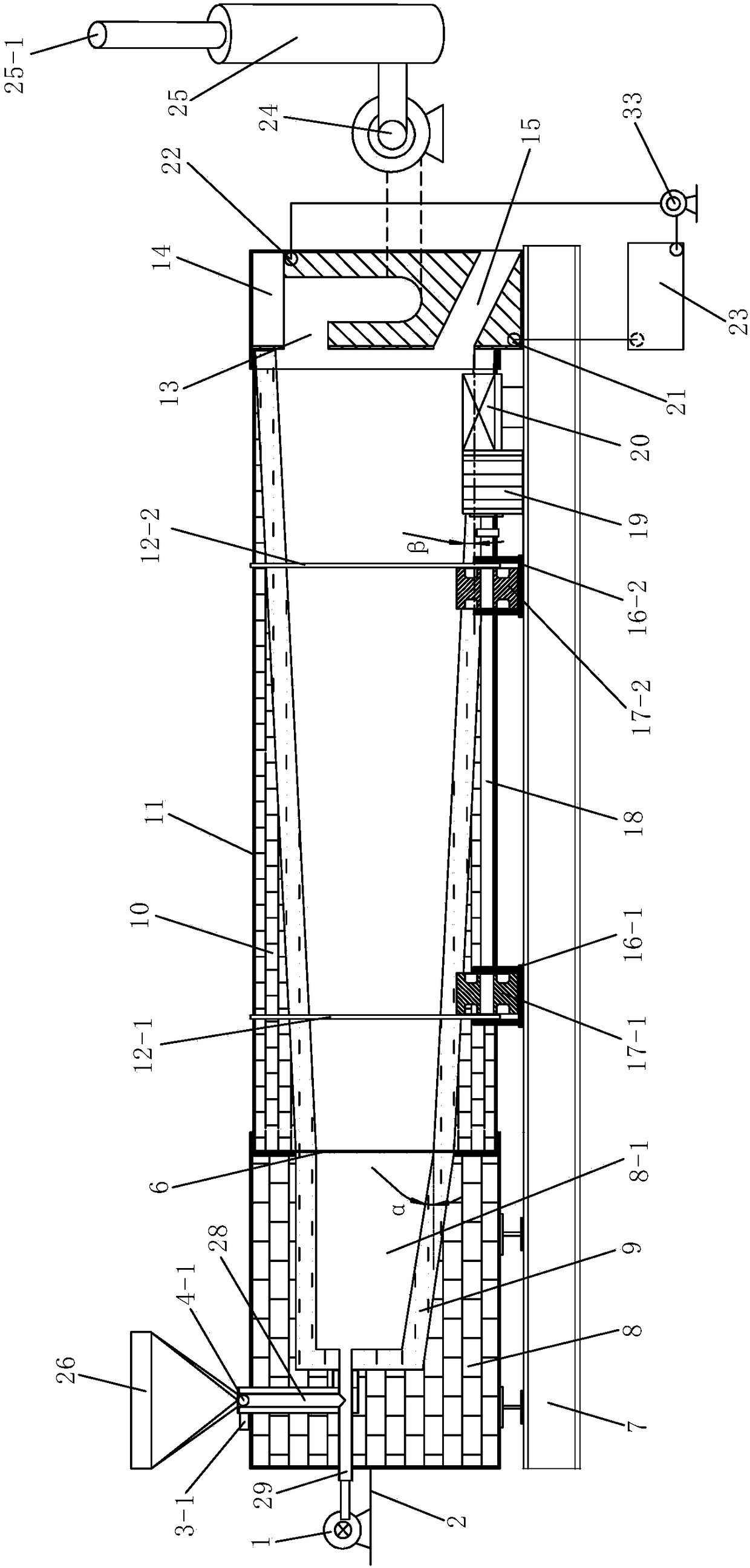

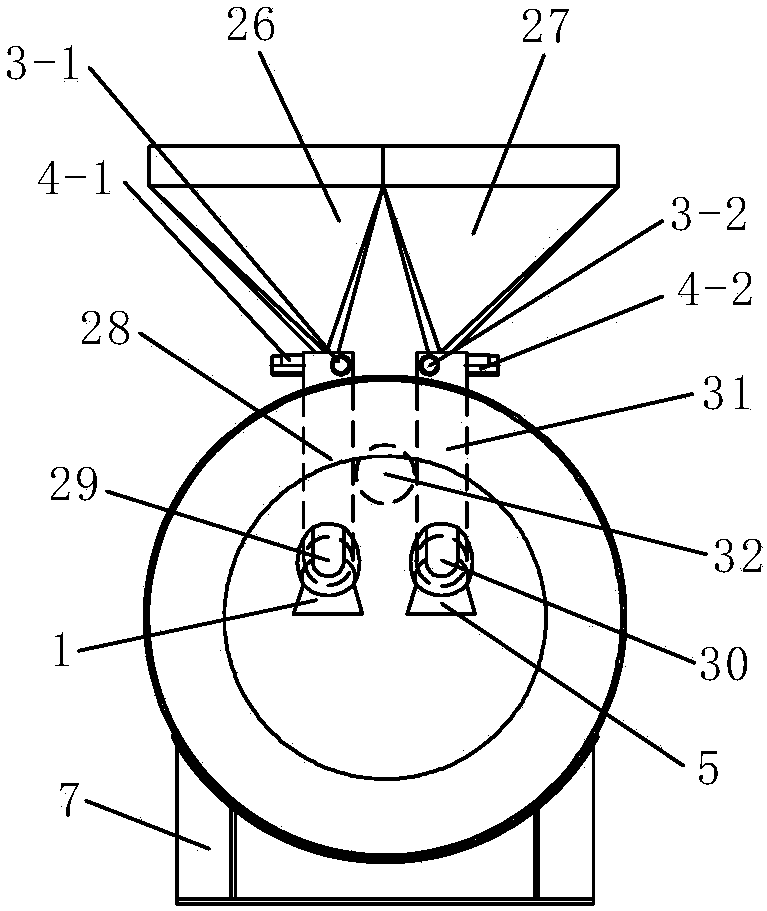

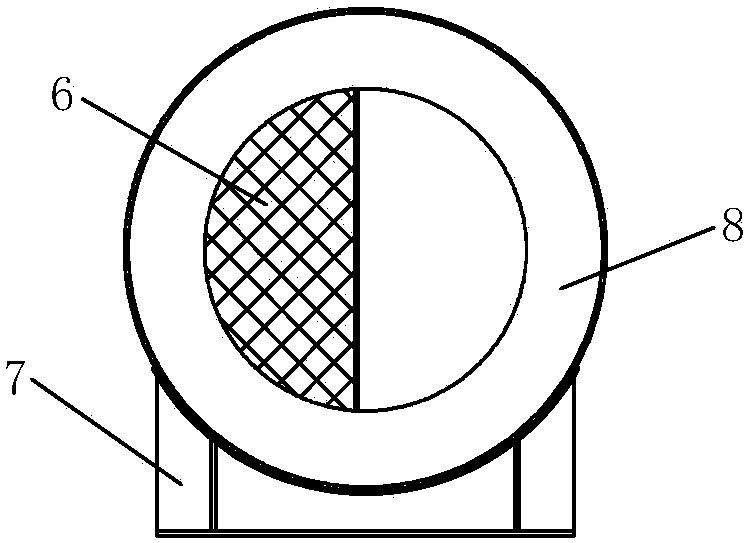

[0044] Such as figure 1 and figure 2 As shown, the present invention includes a kiln body, and the kiln body includes a kiln body head 8, a kiln body middle section 11 and a kiln body tail 14 arranged in sequence from front to back, and the kiln body middle section 11 is connected with the kiln body head 8 and the kiln body The tail parts 14 of the kiln body are all rotatably connected, and a rotary drive mechanism for driving the kiln body is arranged below the middle section 11 of the kiln body. The inner cavity of 11 communicates with the inner cavity of the kiln body tail 14 and the kiln head combustion chamber 8-1, and the front part of the kiln body head 8 is provided with a pulverized coal feeding pipe 28, a material feeding pipe 31, a pulverized coal The air inlet pipe 29 and the material air inlet pipe 30, the pulverized coal air inlet pipe 29 is located below the pulverized coal feeding pipe 28 and communicates with the lower end of the pulverized coal feeding pipe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com