Turbineless jet engines

A jet engine and engine technology, applied in the direction of machines/engines, jet propulsion devices, etc., can solve the problems of complex structure, loss of heat energy, energy consumption, etc., and achieve the effect of simple maintenance and operation, large thrust and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

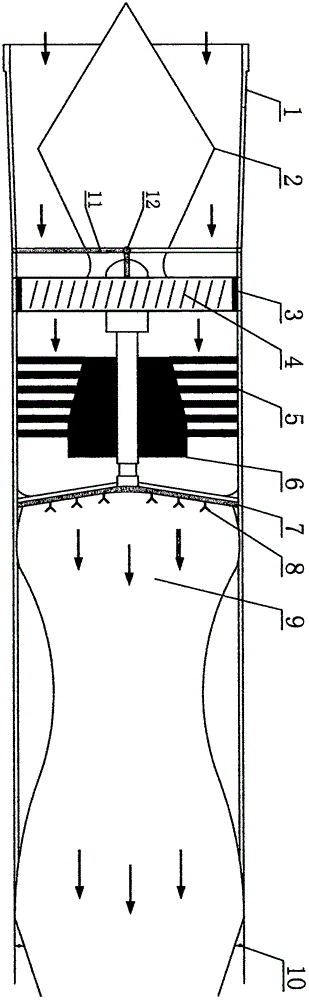

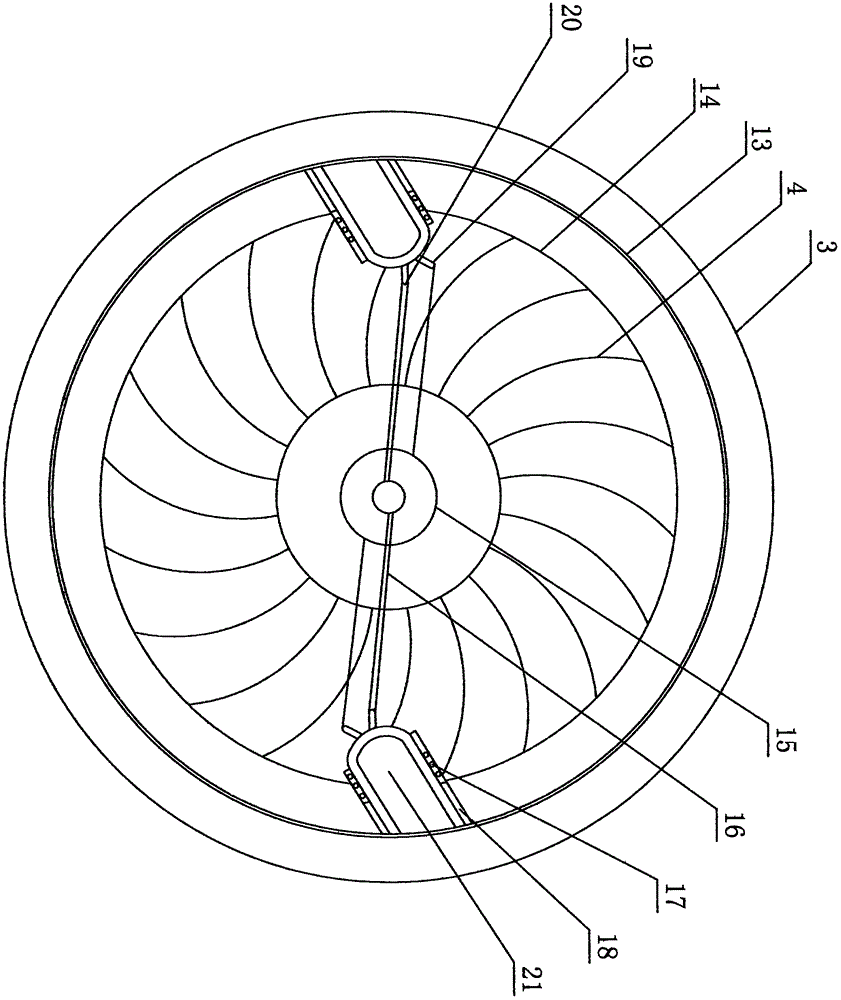

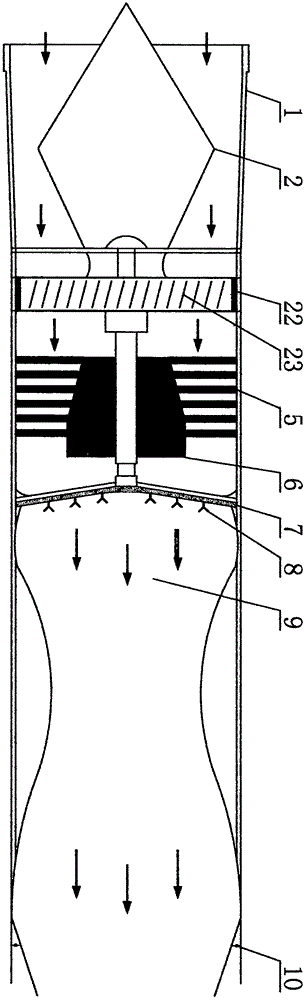

[0012] Such as figure 1 , 2 Shown, a kind of internal-combustion type non-turbine jet engine, it is by it to be combined into one by jet engine part and internal-combustion engine part, jet engine part: comprises housing 1, outer duct, adjustable air inlet 2 , internal combustion engine 3, turbofan 4, compressor 5, swirler 6, oxygen supply and oil supply pipe 7, afterburner nozzle 8, combustion chamber 9, adjustable nozzle 10, gas mixture pipe 11, union 12 , bearing, load-bearing frame, internal combustion engine 3 parts: including outer circle 13, flywheel 14, turbofan 4, shaft 15, gas mixture pipe 16, spring 17, gas ring 18, spark plug 19, injector 20, combustion chamber 21 , brushes, electric wires, computers, instruments and meters, and electronic switches are characterized in that: an air jet hole is arranged at the bottom of the combustion chamber 9, and an afterburner nozzle 8 and a spark plug are installed, and a part of the outer circle 13 of the internal combustion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com