A kind of sliding compound friction and wear test device and its method

A friction and wear test, punching and sliding technology, applied in measuring devices, testing wear resistance, instruments, etc., can solve the problems of less development, difficulty in reproduction or simulation, etc., and achieve large punching and sliding strokes, good self-locking performance, accurate lifting and lowering. The effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

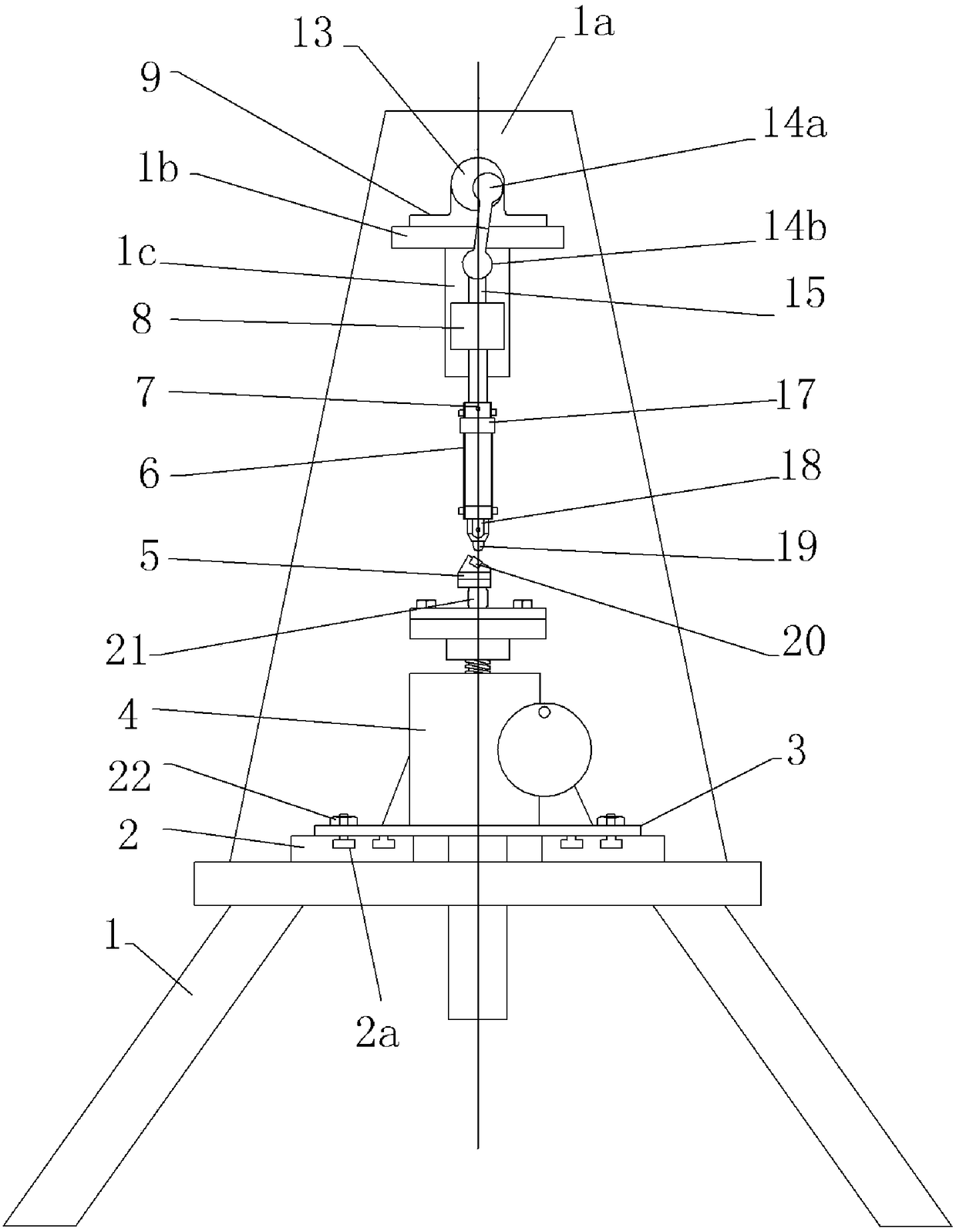

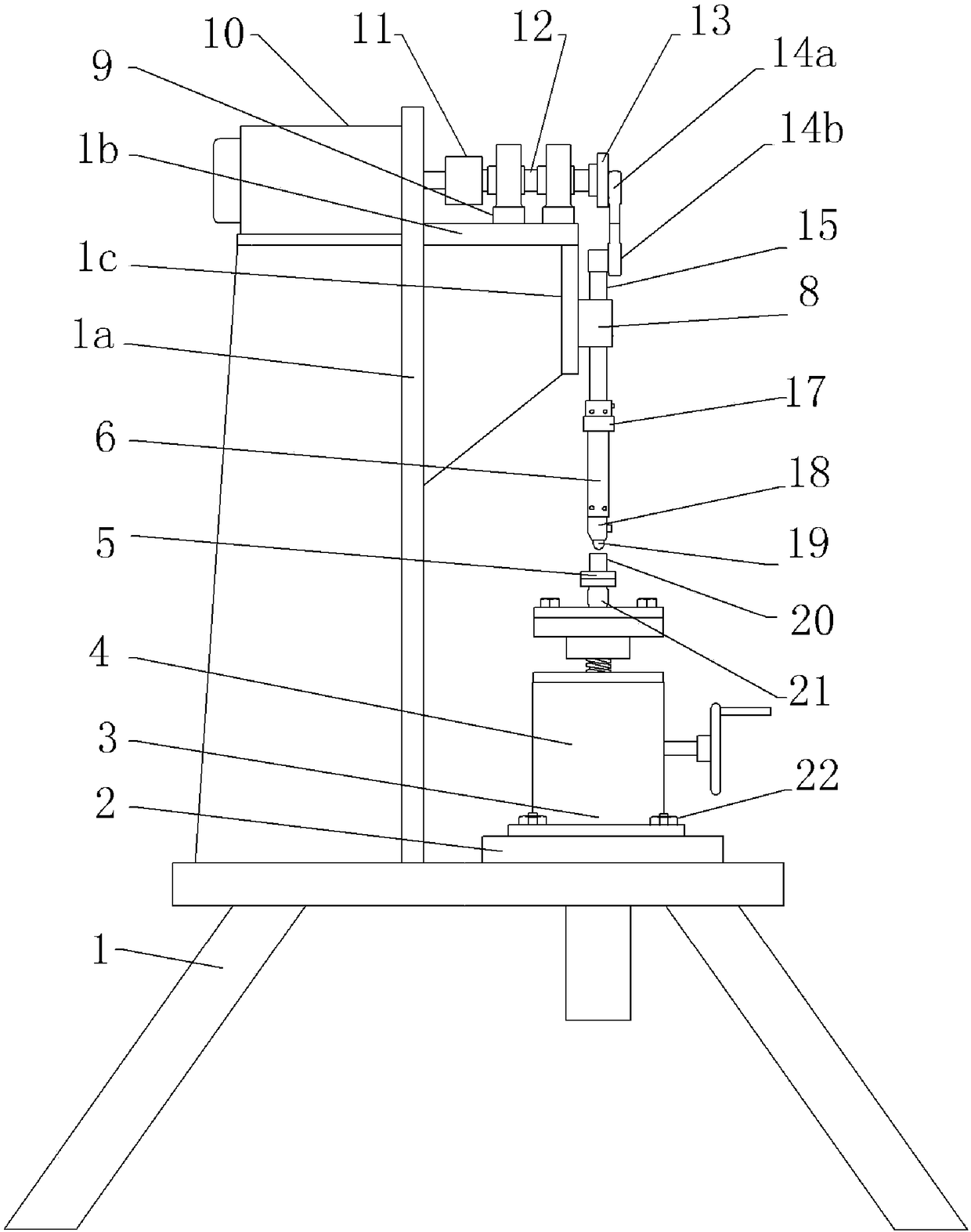

[0034] figure 1 , figure 2 It is shown that a specific embodiment of the present invention is an impact-slip composite friction and wear test device, which is characterized by:

[0035] A precision screw lifting platform 4 is installed on the workbench 2 in the lower part of the frame 1, a three-dimensional dynamic piezoelectric sensor 21 is installed on the top of the precision screw lifting platform 4, and a lower clamp 5 is installed on the top of the three-dimensional dynamic piezoelectric sensor 21;

[0036] The back plate 1a of the upper part of the frame 1 is equipped with a longitudinal servo motor 10, the shaft of the servo motor 10 is connected to the inner center of the eccentric disk 13, and the outer side of the eccentric disk 13 is eccentrically connected to the inner ring of the upper joint bearing 14a, and the upper joint bearing The joint of 14a is connected to the joint of the lower joint bearing 14b, the inner ring of the lower joint bearing 14b is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com