A kind of preparation method of highly sensitive optical ammonia-sensitive material

A sensitive and optical technology, applied in the field of ammonia-sensitive materials, can solve the problems of difficult industrialization, high production cost, complex process, etc., and achieve the effect of easy industrialization, fast response speed and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

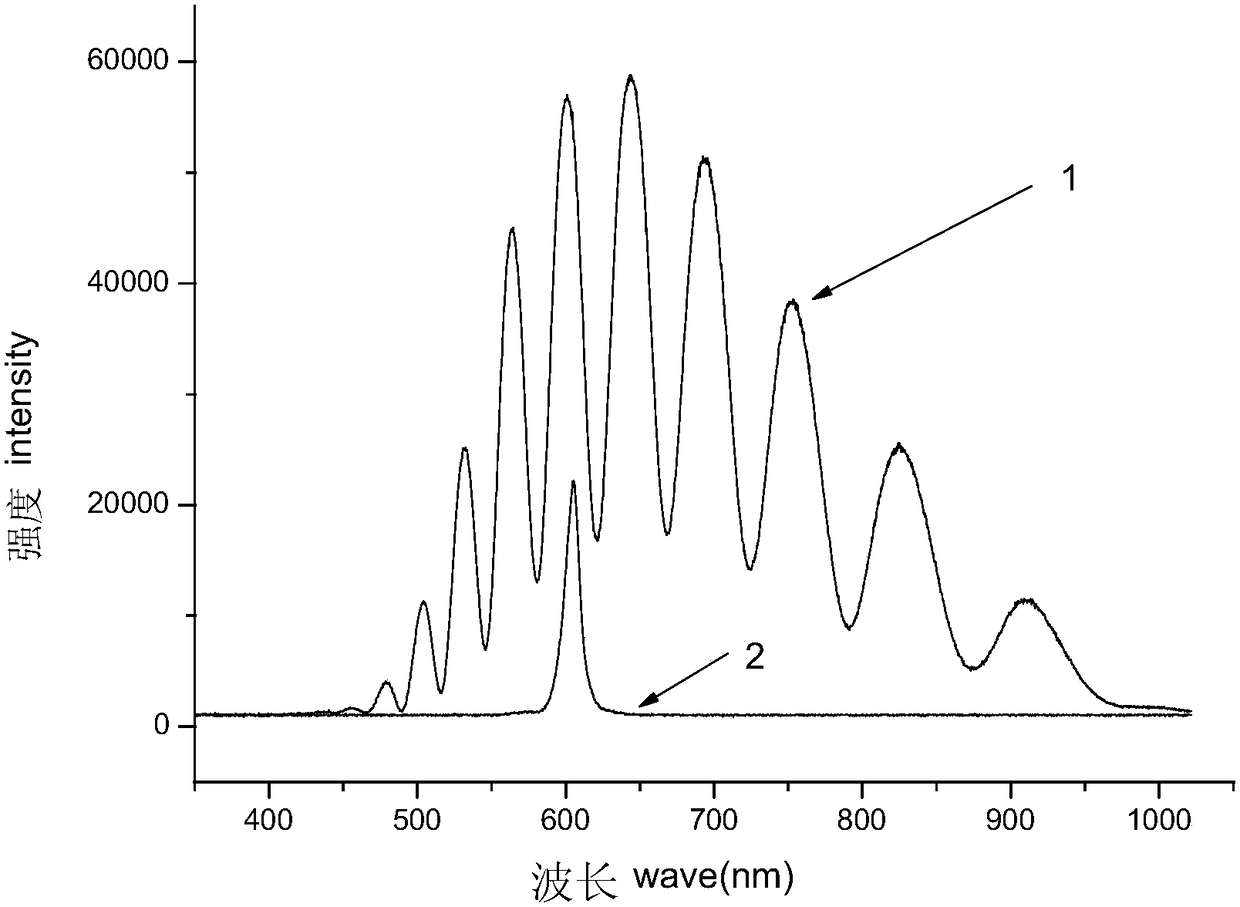

Method used

Image

Examples

Embodiment 1

[0036] Preparation of nanoporous materials: use a solution mixed with hydrofluoric acid / ethanol / glycerol with a volume ratio of 3.5:1:0.005 as the electrolyte, and perform DC etching with an average etching current of 20mA / cm 2 , the etching time is 1200s, rinse with ethanol after etching, and dry with nitrogen to obtain nanoporous materials.

[0037] Preparation of the porous material carrier: the nanoporous material was oxidized at 550° C. for 1 hour to obtain the porous material carrier.

[0038]Preparation of ammonia-sensitive materials: Bromothymol blue is formulated into an ethanol solution with a mass percentage of 0.1% to form an ethanol solution of bromothymol blue, and then mixed with an aqueous solution of acetic acid with a mass percentage of 2% at a volume ratio of 10:0.5 for proton chemical treatment, and then loaded onto the surface of the porous material carrier by spin coating, and dried in a vacuum oven to obtain highly sensitive optical ammonia-sensitive mat...

Embodiment 2

[0041] Preparation of nanoporous materials: use a solution mixed with hydrofluoric acid / ethanol / glycerol with a volume ratio of 3.5:1:0.0005 as the electrolyte, and conduct DC etching with an average etching current of 100mA / cm 2 , the etching time is 200s, rinse with ethanol after etching, and blow dry with nitrogen to obtain nanoporous materials.

[0042] Preparation of the porous material carrier: the nanoporous material was oxidized at 450° C. for 3 hours to obtain the porous material carrier.

[0043] Preparation of ammonia-sensitive material: Bromocresol green is formulated into a 1% by mass ethanol solution to form an ethanol solution of bromcresol green, and then mixed with 2% by mass acetic acid solution at a volume ratio of 10:2 for proton chemical treatment, and then loaded onto the surface of the porous material carrier by dip-dyeing, and dried in a vacuum oven to obtain highly sensitive optical ammonia-sensitive materials.

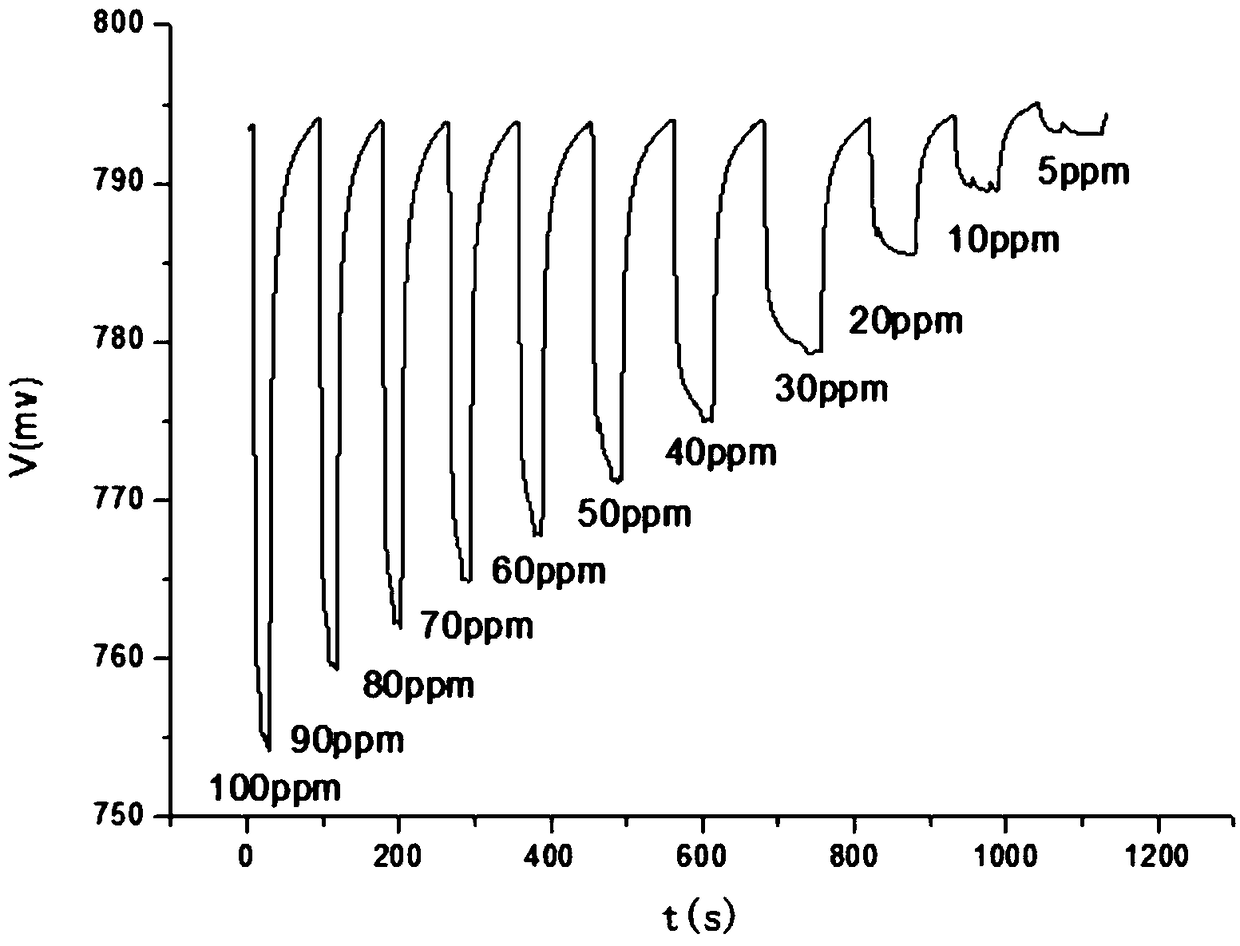

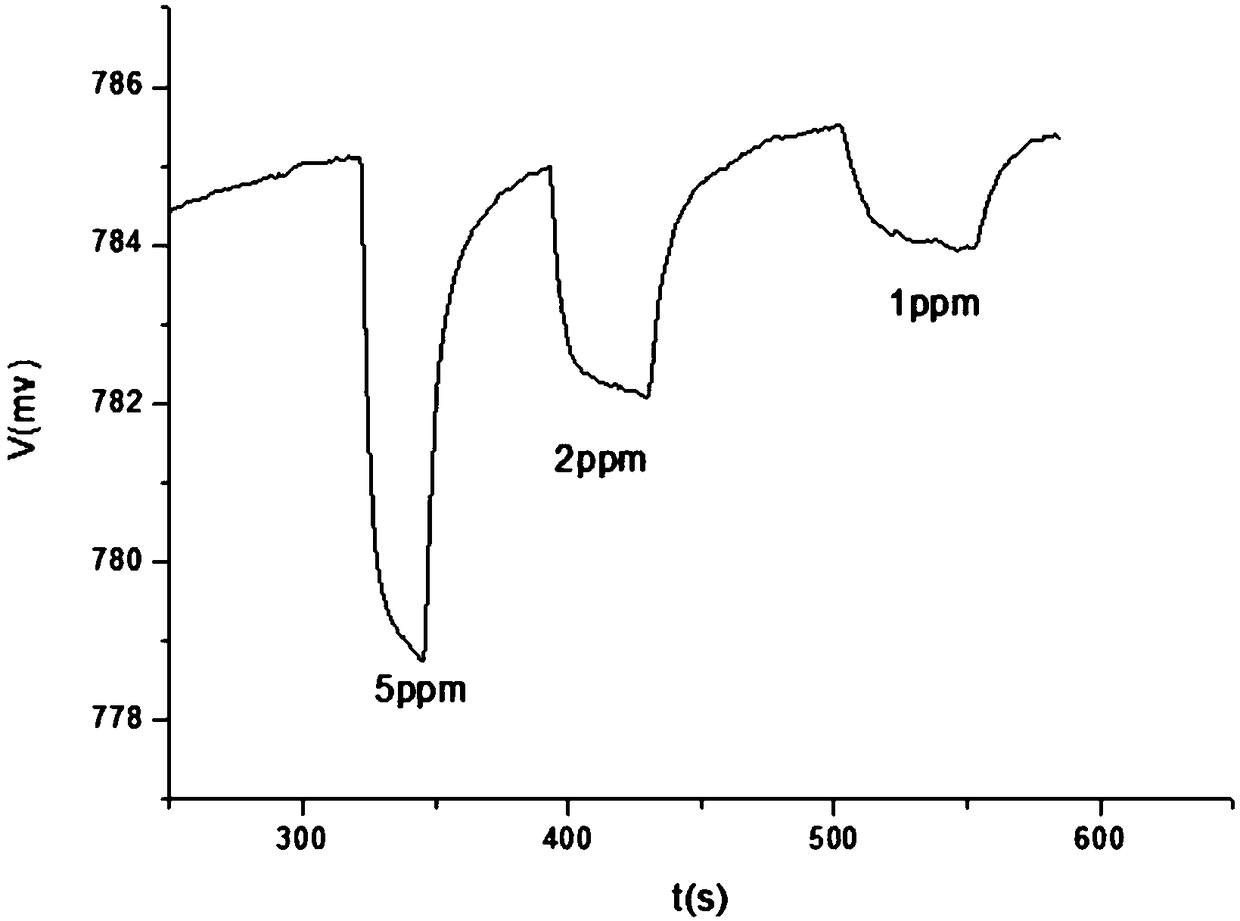

[0044] The ammonia sensor made of this...

Embodiment 3

[0047] Preparation of nanoporous materials: use a solution mixed with hydrofluoric acid / ethanol / glycerol with a volume ratio of 3.5:1:0.0025 as the electrolyte, and conduct DC etching with an average etching current of 60mA / cm 2 , the etching time is 600s, rinse with ethanol after etching, and blow dry with nitrogen to obtain nanoporous materials.

[0048] Preparation of the porous material carrier: the nanoporous material was oxidized at 400° C. for 5 hours to obtain the porous material carrier.

[0049] Preparation of ammonia-sensitive materials: Bromophenol blue is made into 0.5% by mass ethanol solution to form an ethanol solution of bromophenol blue, and then mixed with 2% by mass acetic acid solution at a volume ratio of 10:1.5 for protonation treatment , and then loaded onto the surface of the porous material carrier by drop coating, and dried in a vacuum oven to obtain a high-sensitivity optical ammonia-sensitive material.

[0050] The ammonia sensor made of this ammo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com